Exploring The Wonders Of Electronic Potting Compound From Potting Material Manufacturers

- Electronic Potting Material Manufacturer

- June 12, 2024

- customize china electronic potting silicone factories, customize china electronic potting silicone manufacturer, customize china electronic potting silicone supplier, electrical potting compound, electronic epoxy encapsulant potting compounds, electronic potting compound, electronic potting material, electronic potting silicone manufacturers china, inductor potting thermal management, potting compound for electronics, potting compounds for electronics, potting electronic components, potting electronics, potting material, potting material for electronic components, potting material for electronic compounds, potting material for electronics, silicone potting compound for electronics

Exploring The Wonders Of Electronic Potting Compound From Potting Material Manufacturers

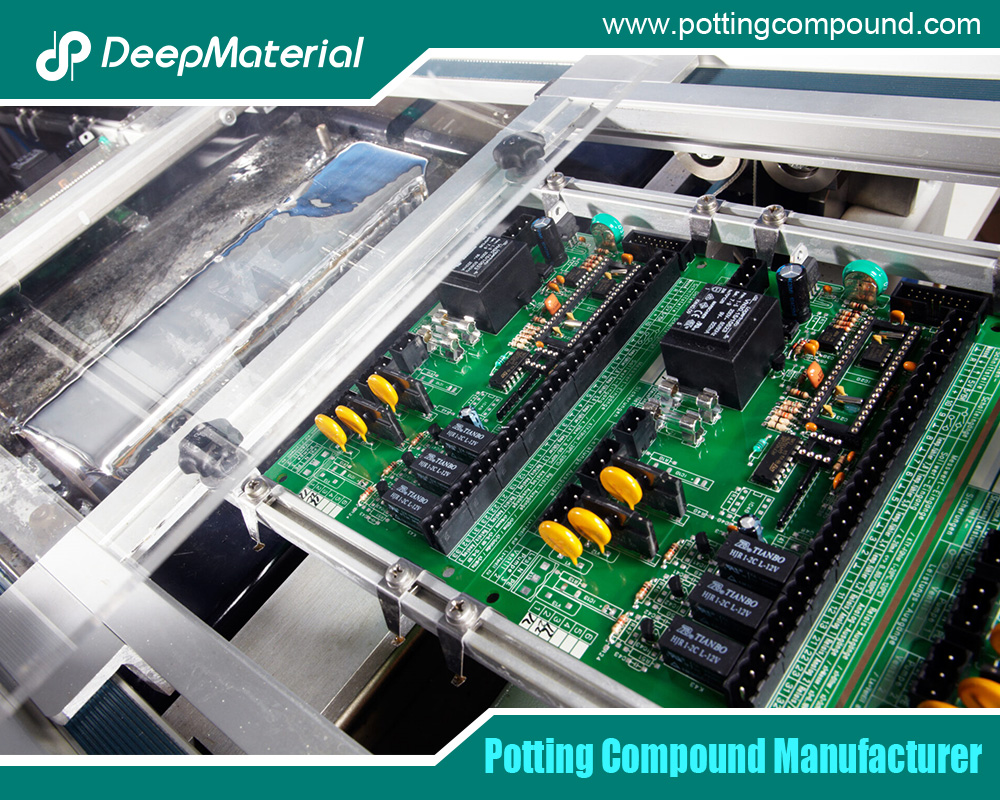

In the intricate world of electronics manufacturing, ensuring the longevity and reliability of electronic components is paramount. The electronic potting compound is a crucial solution in situations like these. Often overlooked but indispensable, electronic potting compounds are vital in protecting sensitive electronic components from environmental factors, moisture, vibration, and other hazards. This blog post aims to explore the world of electronic potting compounds, exploring their uses, benefits, and applications.

What is an Electronic Potting Compound?

An electronic potting compound is a specialized material that encapsulates electronic components, protecting them from environmental factors such as moisture, dust, chemicals, and physical shock. It typically comes as a liquid resin or gel-like substance composed of epoxy, polyurethane, silicone, or other polymers. The primary purpose of electronic potting compounds is to create a protective barrier around electronic assemblies, safeguarding them against damage and ensuring their reliability and longevity. This compound is essential in various industries where electronic components are exposed to harsh conditions, such as automotive, aerospace, consumer electronics, industrial automation, and renewable energy.

Benefits of Electronic Potting Compound

Electronic potting compound offers a range of advantages that contribute to the reliability and longevity of electronic assemblies. Here are some key benefits:

Enhanced Protection:

- Creates a protective barrier around electronic components, shielding them from moisture, dust, chemicals, and other environmental hazards.

- The electronic potting compound prevents corrosion, electrical shorts, and damage caused by physical shock or vibration.

- Extends the lifespan of electronic devices by safeguarding sensitive circuitry from wear and tear.

Improved Thermal Management:

- It helps dissipate heat generated by electronic components, reducing the risk of overheating and thermal damage.

- Enhances electronic devices’ overall performance and efficiency by maintaining optimal operating temperatures.

- Ensures reliable operation of electronic assemblies in demanding thermal environments.

Vibration Damping:

- Absorbs mechanical shock and vibration, minimizing the risk of component failure and solder joint cracking.

- It provides stability and reliability in applications subjected to constant movement or mechanical stress.

- It protects delicate components from damage both during transportation and operation.

Electrical Insulation:

- It acts as an insulator, preventing electrical leakage and short circuits between conductive elements.

- Improves safety by reducing the risk of electric shock and fire hazards in electronic devices.

- Enhances the reliability and performance of electronic assemblies by maintaining electrical isolation.

Versatility:

- Compatible with a wide range of electronic components, substrates, and encapsulation techniques.

- It can be tailored to meet specific application requirements, such as flexibility, hardness, and chemical resistance.

- It suits various industries and applications, including automotive, aerospace, consumer electronics, industrial automation, and renewable energy.

Electronic potting compound offers comprehensive protection, thermal management, vibration damping, electrical insulation, and versatility, making it an essential material for ensuring the reliability and longevity of electronic assemblies across diverse industries.

Applications of Electronic Potting Compound

Electronic potting compounds find diverse applications across industries, safeguarding electronic components from environmental hazards and enhancing reliability and longevity. The demand for these compounds is expected to increase as technology advances, driven by the need for robust protection in various electronic systems and devices.

Electronics Protection

- The encapsulation of sensitive electronic components such as PCBs, sensors, and microchips enhances their protection.

- Shields components from moisture, heat, and mechanical stress, ensuring reliability.

Automotive Electronics

- Potting ECUs, sensors, and connectors effectively withstand vibration, thermal shock, and chemical exposure.

- It enhances the performance and durability of vehicle electronics, which is crucial for safety.

Aerospace and Defense

- Potting avionics systems, radar equipment, and navigation devices are essential for ensuring their functionality in extreme conditions.

- It withstands temperature fluctuations, altitude changes, and harsh environments reliably.

Renewable Energy Systems

- It protects solar inverters, wind turbine control, and battery management systems from environmental damage and electrical hazards.

- It guards against UV radiation, humidity, and temperature variations, prolonging its lifespan.

Industrial Electronics

- Encapsulating industrial sensors, actuators, and control panels enhances their durability and performance in harsh environments.

- Shields components from chemicals, dust, and debris in industrial settings, ensuring reliability.

Choosing the Right Electronic Potting Compound

Selecting the appropriate electronic potting compound is essential for ensuring the reliability and performance of electronic assemblies. With a wide range of formulations available, choosing the suitable compound requires careful consideration of environmental conditions, compatibility, cure time, and mechanical properties. This section outlines guidelines for selecting the most appropriate electronic potting compound for specific applications.

Environmental Conditions:

- Consider the operating environment, including temperature, humidity, and exposure to chemicals or solvents.

- Choose a potting compound that can withstand the anticipated environmental conditions without degradation or loss of performance.

- Select specialized formulations for extreme environments such as automotive, aerospace, or industrial applications.

Compatibility:

- Ensure compatibility with the materials used in the electronic assembly, including substrates, components, and coatings.

- Verify compatibility with adhesives, sealants, and other materials that may come into contact with the potting compound.

- Test compatibility with potential contaminants or environmental factors affecting the compound’s performance.

Cure Time and Process:

- Evaluate the required cure time and process compatibility with production requirements and assembly methods.

- Select a potting compound with the desired cure profile, temperature, and humidity.

- Consider factors such as pot life, working time, and reactivity to optimize the potting process and minimize production time.

Mechanical Properties:

- Assess the mechanical properties of the potting compound, including flexibility, hardness, and impact resistance.

- Choose a compound with mechanical properties that match the application’s requirements, such as thermal cycling, vibration, or mechanical stress.

- For specific performance criteria, consider additional properties such as thermal conductivity, flame resistance, and dielectric strength.

By considering factors such as environmental conditions, compatibility, cure time, and mechanical properties, manufacturers can select the most suitable electronic potting compound for their specific application requirements. They ensure optimal electronic assemblies’ performance, reliability, and longevity in various industries and environments.

Best Practices for Using Electronic Potting Compound

Effective use of electronic potting compounds is crucial for ensuring the reliability and longevity of electronic assemblies. Adhering to best practices can optimize the encapsulation process and enhance the performance of electronic devices. Below are some critical guidelines for using electronic potting compounds efficiently.

Proper Mixing:

- Follow the manufacturer’s instructions for mixing ratios and procedures.

- Use calibrated equipment to ensure accurate measurements.

- Mix thoroughly to achieve uniform consistency and avoid air pockets.

Degassing:

- Eliminate air bubbles by degassing the compound before application.

- Utilize vacuum chambers or other degassing techniques for optimal results.

- Ensure complete removal of trapped air to prevent voids in the encapsulation.

Encapsulation Technique:

- Choose the most suitable method based on the size and complexity of the assembly.

- Consider factors such as vacuum potting, pressure potting, or dip coating for uniform coverage.

- Apply the compound evenly to ensure all components are adequately protected.

Cure and Curing Conditions:

- Allow sufficient curing time as per the manufacturer’s recommendations.

- Maintain appropriate temperature, humidity, and atmospheric pressure during curing.

- Monitor curing parameters closely to prevent under-curing or over-curing.

Quality Control:

- Implement strict quality control measures to detect any defects or inconsistencies.

- Conduct regular inspections and testing of encapsulated assemblies.

- Ensure compliance with industry standards and specifications to uphold quality standards.

By following these best practices, manufacturers can maximize the effectiveness of electronic potting compounds and ensure the reliability of electronic assemblies in various applications.

Conclusion

Electronic potting compound may seem like a small detail in the vast landscape of electronics manufacturing, but its impact is profound. Electronic potting compounds contribute to electronic devices’ reliability, performance, and longevity across various industries by providing robust protection, thermal management, and insulation. As technology advances and the demand for more durable and efficient electronics grows, the role of electronic potting compounds will only become more indispensable. By understanding its uses, benefits, and best practices, manufacturers can harness the full potential of electronic potting compounds to create electronic assemblies that stand the test of time.

For more about exploring the wonders of electronic potting compound from potting material manufacturers,you can pay a visit to DeepMaterial at https://www.pottingcompound.com/electronic-potting-compound/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?