Unleashing the Power of Waterproof Potting Compound: Enhancing Durability in Electronics

- Electronic Potting Material Manufacturer

- July 16, 2024

- Automotive potting material manufacturers, Benefits of Potting Electronics, circuit board potting compound, custom automated electronics potting, deepmaterial PCB Potting, electrical potting compound, electronic epoxy encapsulant potting compounds, Electronic Potting and Encapsulation, Electronic Potting and Encapsulation Resins, electronic potting compound, Electronic Potting Compounds Manufacturer, electronic potting material, epoxy potting compound manufacturers, LED Potting Compound, PCB Potting Compound, polyurethane potting compound, polyurethane potting compound for electronics, Polyurethane Potting Compound Manufacturer, potting compound for electronics, potting compound for pcb, waterproof potting compound

Unleashing the Power of Waterproof Potting Compound: Enhancing Durability in Electronics

Durability is a paramount concern in electronics. Whether a device is exposed to harsh environmental conditions or submerged in water, the need for protection against moisture and other elements is undeniable. This is where waterproof potting compound comes into play, offering a robust solution to safeguard electronic components. This article delves into the significance of waterproof potting compounds and explores their diverse applications across various industries.

Waterproof Potting Compound: A Shield Against Environmental Threats

- Enhanced Protection:Waterproof potting compound forms a protective barrier around electronic components, shielding them from moisture, dust, chemicals, and other environmental hazards. This ensures prolonged durability and reliability of the devices, even in the harshest conditions.

- Versatility:One key advantage of waterproof potting compound is its versatility. It can be customized to meet specific requirements, including temperature resistance, flexibility, and adhesion properties. This versatility makes it suitable for various automotive, aerospace, marine, and consumer electronics applications.

- Improved Performance:Manufacturers can enhance their performance and longevity by encapsulating electronic assemblies in waterproof potting compounds. The compound helps dissipate heat, reduce the risk of thermal damage, and prevent contaminants’ ingress, optimizing the devices’ overall efficiency.

- Cost-Effectiveness:Investing in a waterproof potting compound upfront can save long-term costs. By preventing premature failures and minimizing the need for repairs or replacements, manufacturers can reduce maintenance costs and enhance the lifespan of their products, ultimately improving the bottom line.

- Environmental Sustainability:In an era where environmental consciousness is paramount, waterproof potting compound offers a sustainable solution. Extending the lifespan of electronic devices and reducing electronic waste contribute to a more eco-friendly approach to manufacturing and consumption.

Applications Across Industries

- Automotive:In the automotive industry, waterproof potting compound protects electronic components in vehicles, including sensors, control units, and ignition systems, from moisture, vibrations, and temperature fluctuations. This ensures reliable performance even in challenging driving conditions.

- Aerospace:In aerospace applications, where electronics are exposed to extreme temperatures, pressure changes, and humidity levels, a waterproof potting compound is crucial in safeguarding critical systems such as avionics, communication devices, and navigation equipment, ensuring uninterrupted operation.

- Marine:On ships and offshore platforms, where exposure to saltwater and corrosive environments is inevitable, waterproof potting compound protects electronic systems, preventing corrosion and electrical failures that could compromise safety and operational efficiency.

- Consumer Electronics:Waterproof potting compounds are increasingly used in consumer electronics products such as smartphones, tablets, and wearable devices to make them more resistant to water damage, extend their lifespan, and enhance their appeal to consumers who value durability and reliability.

The Science Behind Waterproofing: How Potting Compound Works

Waterproof potting compounds are vital in various industries. They protect sensitive electronic components from moisture and environmental factors. Understanding the science behind their effectiveness unveils the intricate mechanisms at play.

Mechanism of Action:

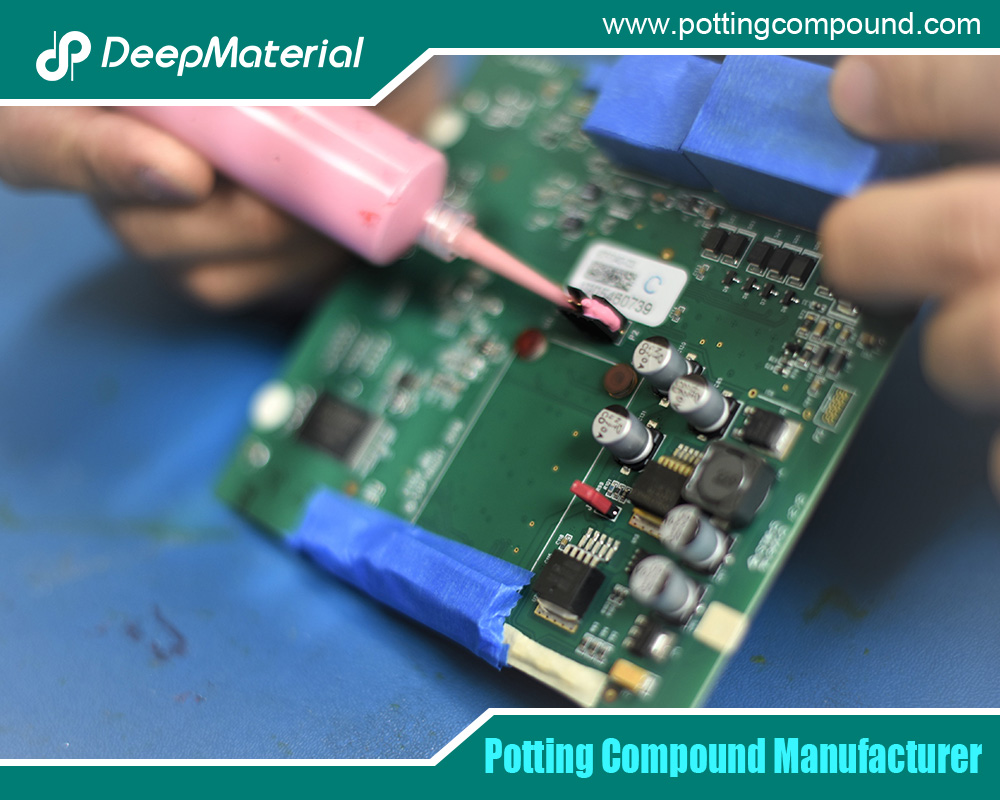

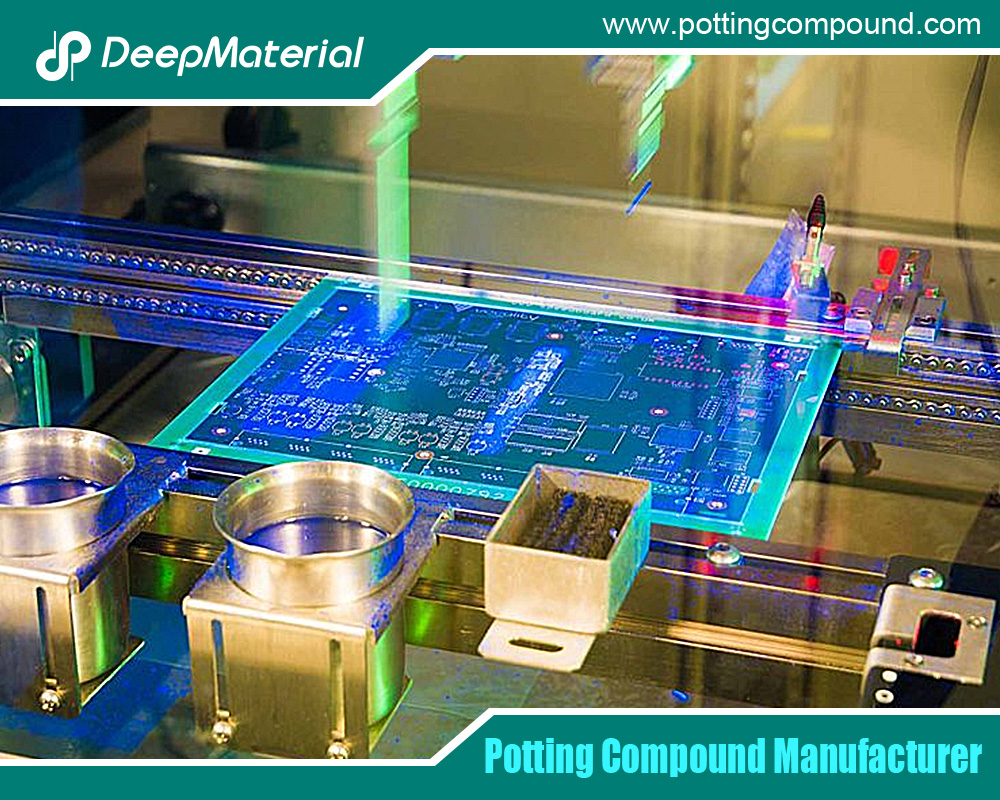

- Encapsulation:Potting compounds form a robust barrier around electronic assemblies, encapsulating them entirely.

- Chemical Composition: Typically, these compounds consist of polymers such as epoxy, silicone, or urethane, offering both flexibility and durability.

- Crosslinking:Chemical reactions within the compound create a three-dimensional network, enhancing its structural integrity.

Key Features:

- Water Resistance: Potting compounds repel water, preventing it from infiltrating sensitive electronics.

- Chemical Stability: Resistant to various chemicals, ensuring prolonged protection even in harsh environments.

- Thermal Conductivity:Some formulations offer efficient heat dissipation, which is crucial for maintaining optimal operating temperatures.

- Electrical Insulation: Prevents short circuits by insulating components from moisture and contaminants.

Working Principles:

- Hydrophobicity: The inherent hydrophobic nature of the compound repels water molecules, preventing them from penetrating the encapsulated area.

- Adhesion:Strong adhesion properties ensure the compound forms a tight seal around components, minimizing the chances of water ingress.

- Flexibility:Allows the compound to adapt to the expansion and contraction of materials due to temperature variations without compromising its integrity.

- Curing Process:Upon application, the compound undergoes a curing process, transforming from a liquid to a solid, impenetrable barrier.

Applications:

- Electronics: Used extensively in electronic devices, from consumer electronics to industrial control systems, safeguarding circuitry from moisture damage.

- Automotive:Protects electronic control units (ECUs), sensors, and vehicle wiring harnesses from water ingress, ensuring reliable operation.

- Aerospace:Vital in aerospace applications, where electronic components are exposed to extreme conditions, including high altitude and temperature fluctuations.

- Renewable Energy: Plays a crucial role in solar inverters, wind turbine control systems, and battery management systems, prolonging their lifespan in outdoor environments.

Environmental Testing and Certification Standards for Waterproof Potting Compounds

Waterproof potting compounds are essential materials used in various industries to protect electronic components from moisture, chemicals, and other environmental hazards. These compounds undergo rigorous testing and certification based on industry standards to ensure their effectiveness and reliability. Here’s a breakdown of the environmental testing and certification standards for waterproof potting compounds:

- IP Rating Testing:The Ingress Protection (IP) rating system assesses the degree of protection provided by enclosures against solids and liquids. Waterproof potting compounds are subjected to IP rating tests to evaluate their resistance to water ingress. Standard IP ratings include IP67, indicating protection against immersion up to 1 meter for 30 minutes, and IP68, which signifies protection against continuous immersion beyond 1 meter.

- ASTM Standards:The American Society for Testing and Materials (ASTM) sets standards for the performance and quality of materials, including waterproof potting compounds. ASTM D570 outlines the standard test method for water absorption of plastics, providing guidelines for measuring the water absorption of potting compounds under controlled conditions.

- UL Certification: Underwriters Laboratories (UL) certification is widely recognized as a mark of product safety and reliability. Waterproof potting compounds may undergo UL testing to verify their compliance with specific standards, such as UL 94 for flammability and UL 746C for polymeric materials used in electrical equipment.

- IEC Standards:The International Electrotechnical Commission (IEC) develops international standards for electrical and electronic technologies. IEC 60529 establishes testing procedures for determining the degree of protection enclosures provide against water ingress and foreign objects. Waterproof potting compounds are evaluated according to IEC 60529 to ensure they meet specified ingress protection levels.

- Salt Spray Testing:Salt spray testing, or ASTM B117 testing, assesses the corrosion resistance of materials exposed to a saline environment. Waterproof potting compounds may undergo salt spray testing to simulate harsh marine or coastal conditions and evaluate their long-term durability and resistance to corrosion.

- Temperature and Humidity Testing:Environmental chambers subject waterproof potting compounds to temperature and humidity cycling tests. These tests simulate real-world conditions, including extreme temperatures and humidity levels, to assess the compound’s stability and performance over time.

- Environmental Compliance:Besides performance testing, waterproof potting compounds must comply with various environmental regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Compliance with these regulations ensures the compounds’ and their components’ safety and sustainability.

Conclusion

Waterproof potting compound is a game-changer in electronics, offering a robust solution to protect electronic components from environmental threats. Its versatility, effectiveness, and cost-effectiveness make it indispensable across industries, from automotive and aerospace to marine and consumer electronics. By investing in waterproof potting compounds, manufacturers can enhance their products’ durability, performance, and sustainability, ensuring they withstand the test of time in even the most challenging conditions.

For more about Unleashing the Power of Waterproof Potting Compound: Enhancing Durability in Electronics, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?