Electronic Epoxy Encapsulant Potting Compounds: Enhancing Performance and Reliability in Modern Electronics

- Electronic Potting Material Manufacturer

- July 17, 2024

- circuit board potting compound, Connector Potting Compound, electrical potting compound, electronic encapsulant potting compounds, electronic epoxy encapsulant potting compounds, electronic potting compound, electronic potting compounds, Electronic Potting Compounds Manufacturer, encapsulant potting compounds, Encapsulants and Potting Compounds Suppliers, epoxy encapsulant potting compounds, epoxy potting compound, epoxy potting compound manufacturers, Flexible Potting Compound, LED Potting Compound, PCB Potting Compound, polyurethane potting compound, polyurethane potting compound for electronics, Polyurethane Potting Compound Manufacturer, polyurethane potting compound manufacturers china, potting compound for electronics, potting compound for pcb

Electronic Epoxy Encapsulant Potting Compounds: Enhancing Performance and Reliability in Modern Electronics

The protection and reliability of electronic components are paramount in modern electronics manufacturing. Electronic epoxy encapsulant potting compounds safeguard delicate electronics from environmental stresses, mechanical damage, and chemical exposure. This article explores in detail the various aspects of these compounds, from their composition and properties to applications across different industries and emerging trends in their development.

- Understanding Electronic Epoxy Encapsulant Potting Compounds

Electronic epoxy encapsulant potting compounds are specialised materials that encase or encapsulate electronic components such as circuit boards, sensors, and modules. They are formulated to provide a protective barrier that shields these components from moisture, dust, vibrations, and other external factors that could compromise their functionality and longevity.

1.1 Composition and Basic Properties

Electronic epoxy encapsulant potting compounds typically consist of epoxy resins as the primary binder, curing agents, fillers, and additives. Epoxy resins offer excellent adhesion to various substrates and provide robust mechanical and chemical properties. Curing agents initiate cross-linking, transforming the liquid resin into a solid, durable material.

1.2 Role in Protecting Electronic Components

The primary function of these potting compounds is to create a protective barrier around electronic components. By encapsulating them, the compounds prevent moisture ingress, which can lead to corrosion and short circuits. They also enhance mechanical stability, protecting components from physical shock and vibration.

1.3 Types and Variants

Electronic epoxy encapsulant potting compounds are available in several formulations to suit different application requirements:

- Epoxy-Based Compounds:Known for their high mechanical strength and chemical resistance, epoxy-based compounds are widely used in applications where robust protection is crucial, such as automotive and aerospace electronics.

- Silicone-Based Compounds:Silicone potting compounds offer excellent flexibility and thermal stability over a wide temperature range, making them suitable for outdoor and high-temperature environments.

- Polyurethane-Based Compounds:These compounds provide good adhesion and flexibility, making them ideal for applications where shock absorption and thermal cycling resistance are essential.

Each type has distinct properties that cater to specific environmental and performance criteria.

- Properties and Benefits

Electronic epoxy encapsulant potting compounds offer a range of beneficial properties that enhance the performance and reliability of encapsulated electronics:

2.1 Electrical Insulation

These compounds provide high dielectric strength, effectively insulating components from electrical currents. This property is crucial in preventing short circuits and electrical malfunctions.

2.2 Thermal Conductivity

Some formulations are designed to enhance thermal conductivity, dissipating heat generated by electronic components. This feature helps maintain optimal operating temperatures and extends the lifespan of sensitive electronics.

2.3 Chemical Resistance and Environmental Protection

Potting compounds, including solvents, fuels, and corrosive substances, shield components from chemical exposure. They also offer protection against environmental factors such as UV radiation, moisture, and dust ingress.

2.4 Mechanical Stability and Impact Resistance

The encapsulation process significantly improves the mechanical stability of electronic assemblies, reducing the risk of damage from physical impacts, vibration, and mechanical stress.

2.5 Long-Term Reliability

These compounds contribute to the long-term reliability of electronic devices by providing a protective barrier and enhancing environmental resilience, reducing maintenance costs and downtime.

- Applications in Electronics

Electronic epoxy encapsulant potting compounds find widespread use across various industries:

3.1 Consumer Electronics

These compounds protect delicate circuitry in consumer electronics, such as smartphones, tablets, and wearables, from everyday wear and tear, moisture, and accidental impacts.

3.2 Automotive Electronics

Automotive applications demand robust protection against temperature variations, vibrations, and exposure to automotive fluids. Potting compounds ensure the reliability of electronic control units (ECUs), sensors, and lighting systems.

3.3 Aerospace and Defense

In aerospace and defence applications, where electronics must withstand extreme temperatures, high altitudes, and rigorous conditions, potting compounds provide critical protection for avionics, radar systems, and communication devices.

3.4 Industrial Equipment

Industrial electronics, including motor drives, power supplies, and control panels, benefit from potting compounds that enhance reliability in harsh industrial environments, such as manufacturing facilities and outdoor installations.

- Factors to Consider When Choosing Potting Compounds

Selecting the suitable potting compound involves considering several factors:

4.1 Compatibility with Electronic Components

Compounds must be compatible with the materials used in electronic components to ensure proper adhesion and performance.

4.2 Environmental Factors

Environmental conditions such as temperature extremes, humidity levels, and chemical exposure dictate the choice of potting compound formulation.

4.3 Curing Time and Process

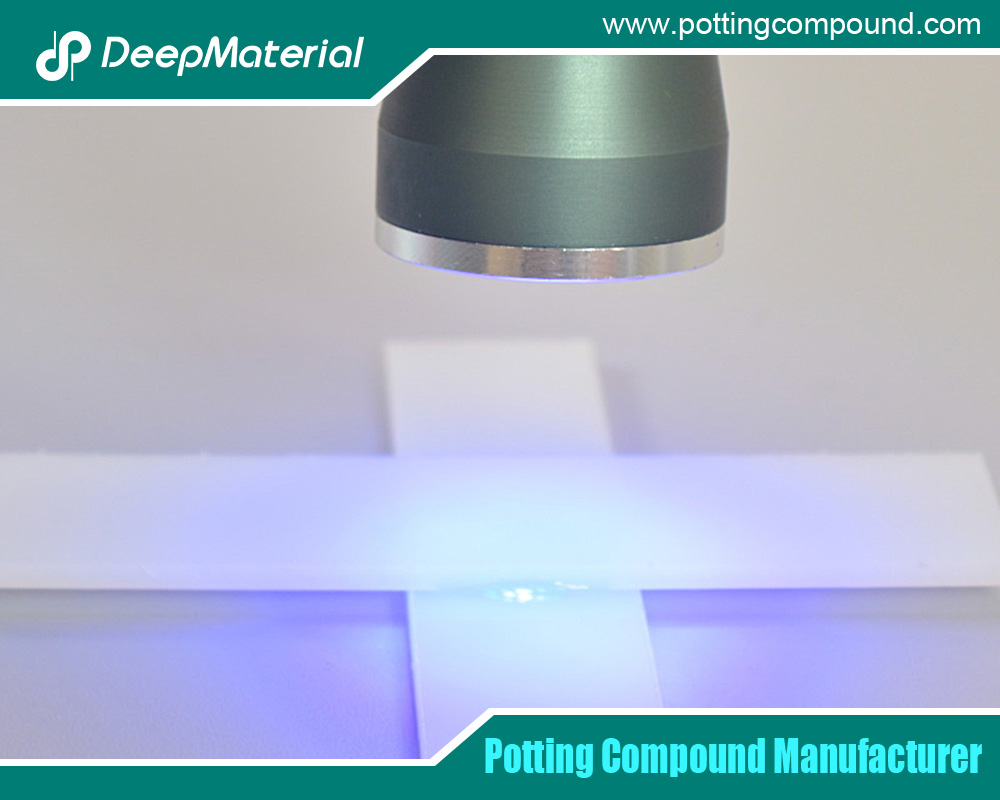

The curing process—whether room temperature, heat-activated, or UV-cured—affects production timelines and assembly processes.

4.4 Application Methods

Manual potting techniques may be suitable for small-scale production or prototyping, while automated dispensing systems ensure consistency and efficiency in large-scale manufacturing.

4.5 Regulatory Compliance

Adherence to regulatory standards such as Restriction of Hazardous Substances (RoHS) and REACH ensures the compounds’ safety and environmental sustainability.

- Application Methods

The method of applying potting compounds varies depending on production requirements and scale:

5.1 Manual Potting

In manual potting, operators carefully apply the compound to electronic assemblies using syringes or dispensing tools. This method allows for precise application but may be labour-intensive for large-scale production.

5.2 Automated Dispensing Systems

Automated dispensing systems use robots or machines to apply potting compounds consistently and efficiently. This method is ideal for high-volume production and ensures uniform encapsulation.

5.3 Challenges and Considerations

Both manual and automated potting methods require careful consideration of material viscosity, pot life, and curing conditions to achieve optimal results.

- Case Studies and Examples

Real-world applications demonstrate the effectiveness of electronic epoxy encapsulant potting compounds in enhancing reliability and performance:

6.1 Example 1: Automotive Electronics

A leading automotive manufacturer uses epoxy-based potting compounds to protect ECUs from moisture and vibrations, ensuring reliable performance in all weather conditions.

6.2 Example 2: Aerospace Applications

In aerospace applications, silicone potting compounds encapsulate avionics systems, providing thermal stability and protection against electromagnetic interference (EMI).

- Future Trends and Innovations

Technological advancements and industry demands drive the evolution of electronic epoxy encapsulant potting compounds:

7.1 Emerging Technologies

Advances in nanotechnology and hybrid materials are leading to developing potting compounds with enhanced thermal conductivity, flexibility, and environmental sustainability.

7.2 Sustainable Practices

Manufacturers increasingly focus on developing eco-friendly formulations that minimize environmental impact without compromising performance.

7.3 Integration with Smart Electronics

Integrating potting compounds with intelligent electronics and flexible substrates enables new applications in wearable devices, IoT sensors, and flexible displays.

Conclusion

Electronic epoxy encapsulant potting compounds are indispensable in ensuring modern electronic devices’ reliability, durability, and performance across various industries. By providing robust protection against environmental stresses and mechanical damage, these compounds contribute to the longevity and functionality of electronic assemblies. As technology advances and new materials are developed, the role of potting compounds in electronics manufacturing will continue to evolve, supporting innovations in automotive, aerospace, consumer electronics, and industrial applications.

For more about the electronic epoxy encapsulant potting compounds: enhancing performance and reliability in modern electronics, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?