PCB Potting Services: A Comprehensive Guide

- Electronic Potting Material Manufacturer

- August 15, 2024

- Automotive potting material manufacturers, Benefits of Potting Electronics, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, conformal coating for pcb, conformal coating for pcb standards, conformal coating pcb, Connector Potting Compound, custom automated electronics potting, customize china electronic potting silicone factories, customize china electronic potting silicone manufacturer, customize china electronic potting silicone supplier, deepmaterial PCB Potting, deepmaterial potting compound, electrical potting compound, electronic encapsulant potting compounds, electronic epoxy encapsulant potting compounds, Electronic Potting and Encapsulation, Electronic Potting and Encapsulation Resins, electronic potting compound, pcb conformal coating, pcb encapsulation, pcb encapsulation epoxy, pcb encapsulation epoxy adhesive glue, pcb potting, PCB Potting Compound, PCB Potting Compound and Conformal Coating Adhesive, PCB potting compounds, PCB potting service, PCB Potting Services, potting compound for pcb, potting pcb, what is pcb potting

PCB Potting Services: A Comprehensive Guide

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, enabling the functionality and performance of everything from smartphones to industrial machinery. As these devices become increasingly sophisticated and sensitive, protecting PCBs becomes paramount. One of the most effective methods for safeguarding PCBs from environmental factors and mechanical damage is through potting. This article delves into PCB potting services, exploring their significance, processes, materials, advantages, and applications.

Understanding PCB Potting

What is PCB Potting?

PCB potting is the process of encasing a PCB in a protective material to shield it from various external factors. The potting material, often a resin, encapsulates the entire board, forming a barrier against moisture, dust, chemicals, and mechanical shocks. This process not only enhances the durability of the PCB but also improves its electrical insulation and thermal management properties.

Why Potting is Essential

The primary purpose of potting is to protect the sensitive components on a PCB from harsh environmental conditions and potential damage. Here are some key reasons why potting is essential:

- Environmental Protection: Potting shields the PCB from moisture, dust, and corrosive chemicals, which can cause short circuits and component degradation.

- Mechanical Stability: The potting material provides mechanical support, reducing the risk of damage from vibrations, impacts, and physical stresses.

- Thermal Management: Certain potting materials have excellent thermal conductivity, helping to dissipate heat generated by the PCB components and preventing overheating.

- Electrical Insulation: Potting materials offer high dielectric strength, ensuring electrical insulation and avoiding short circuits and electrical arcing.

- Enhanced Longevity: Potting significantly extends the device’s lifespan by protecting the PCB from environmental and mechanical factors.

The Potting Process

Step-by-Step Potting Procedure

- Preparation: The PCB is cleaned thoroughly to remove any contaminants that might affect the adhesion of the potting material. Components that do not require potting, such as connectors, are masked off to prevent them from being encapsulated.

- Mixing: The potting material, typically a two-part resin system (such as epoxy, silicone, or polyurethane), is mixed according to the manufacturer’s instructions. Proper mixing is crucial to ensure the material cures correctly and achieves its desired properties.

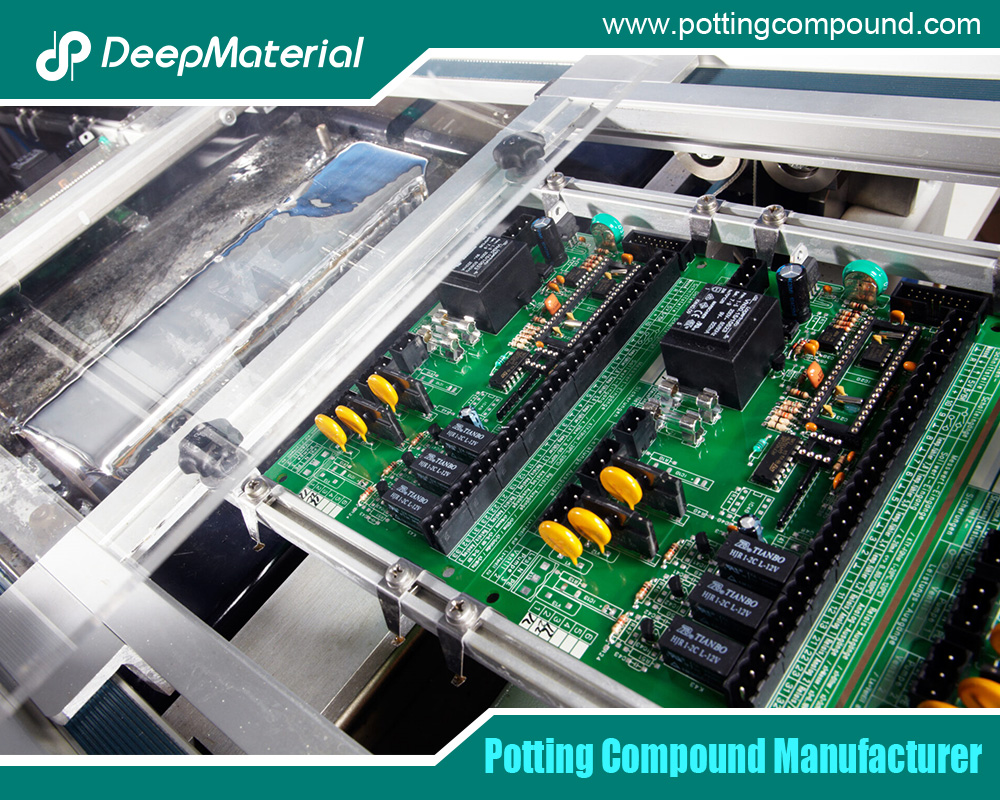

- Dispensing: The mixed potting material is dispensed onto the PCB. This can be done manually or using automated dispensing systems for precise application. The material flows around the components, filling gaps and covering the entire surface.

- Curing: The potted PCB is then left to cure. The curing process can be accelerated using heat or UV light, depending on the type of resin used. Curing ensures that the potting material hardens and forms a robust protective layer.

- Inspection: After curing, the potted PCB is inspected for any defects or voids in the potting material. Proper inspection ensures the effectiveness of the potting process and the integrity of the protection provided.

Materials Used in Potting

Different potting materials offer varying properties, making them suitable for different applications. Here are the most commonly used potting materials:

- Epoxy Resins: Epoxy is known for its excellent adhesion, high mechanical strength, and chemical resistance. It provides strong protection against moisture and physical damage, making it ideal for harsh environments.

- Silicone Resins: Silicone offers flexibility, high-temperature resistance, and excellent electrical insulation properties. It is suitable for applications where thermal management and flexibility are crucial.

- Polyurethane Resins: Polyurethane provides good mechanical properties, chemical resistance, and flexibility. It is often used in applications requiring a balance between hardness and flexibility.

- Acrylic Resins: Acrylic is known for its transparency and UV resistance. It is used in applications where optical clarity is essential, such as LED encapsulation.

Advantages of PCB Potting

Enhanced Durability and Reliability

Potting significantly enhances the durability and reliability of PCBs by providing a robust barrier against environmental and mechanical stressors. This ensures that the electronic components continue to function optimally over extended periods, even in challenging conditions.

Improved Electrical Performance

The high dielectric strength of potting materials ensures excellent electrical insulation, reducing the risk of short circuits and electrical failures. This is particularly important in high-voltage applications where electrical isolation is critical.

Thermal Management

Potting materials with high thermal conductivity help dissipate heat generated by the PCB components. This prevents overheating, ensuring the longevity and performance of the electronic device.

Protection from Moisture and Chemicals

Potting creates a waterproof and chemical-resistant seal around the PCB, preventing moisture ingress and chemical exposure. This is crucial for applications in humid or corrosive environments.

Vibration and Shock Resistance

The mechanical support provided by potting materials reduces the risk of damage from vibrations and mechanical shocks. This is especially important in automotive, aerospace, and industrial applications, where devices are subjected to constant movement and impact.

Applications of PCB Potting

Automotive Industry

The automotive industry uses PCBs in various critical systems, including engine control units, infotainment systems, and safety devices. Potting ensures these systems function reliably under extreme temperature fluctuations, vibrations, and exposure to moisture and chemicals.

Aerospace and Defense

Aerospace and defense applications demand high reliability and durability from electronic components. Potting protects PCBs in avionics, communication systems, and navigation equipment from harsh environmental conditions and mechanical stresses.

Industrial Equipment

Industrial equipment often operates in challenging environments with high dust, moisture, and chemicals—potting shields PCBs in control systems, sensors, and machinery, ensuring consistent performance and longevity.

Consumer Electronics

In consumer electronics, potting protects sensitive components in smartphones, tablets, and wearables from moisture, dust, and physical damage, enhancing their durability and reliability.

Medical Devices

Medical devices require high levels of reliability and safety. Potting protects PCBs in diagnostic equipment, patient monitors, and implantable devices from environmental factors, ensuring accurate and consistent performance.

Telecommunications

PCBs are used in routers, switches, and base stations in telecommunications. Potting protects from moisture, dust, and temperature fluctuations, ensuring reliable communication networks.

Choosing the Right Potting Service Provider

Factors to Consider

Selecting the right potting service provider is crucial for ensuring the quality and effectiveness of the potting process. Here are some factors to consider when choosing a provider:

- Experience and Expertise: Look for providers with extensive experience in PCB potting. Experienced providers are more likely to understand the specific requirements of your application and offer tailored solutions.

- Material Selection: Ensure that the provider provides a range of potting materials and can help you choose the suitable material based on your application needs.

- Quality Control: A reliable provider should have robust quality control processes to ensure their potting services’ consistency and reliability.

- Turnaround Time: Consider the provider’s turnaround time and ability to meet project deadlines.

- Customer Support: Good customer support is essential for addressing any issues or concerns arising during the potting process.

Case Studies and Success Stories

Reviewing case studies and success stories can provide valuable insights into a potting service provider’s capabilities and reliability. Look for providers who have successfully handled projects similar to yours and have a track record of delivering high-quality results.

Challenges and Considerations

Potential Issues in Potting

While potting offers numerous benefits, it also presents some challenges that need to be addressed:

- Void Formation: Voids or air bubbles in the potting material can compromise the protection and insulation provided. Proper mixing and dispensing techniques are essential to minimize void formation.

- Material Compatibility: Ensuring compatibility between the potting material and the PCB components is crucial to avoid chemical reactions or damage.

- Heat Dissipation: While potting materials can improve thermal management, improper application can lead to heat buildup and potential overheating. Careful consideration of the thermal properties of the potting material is essential.

- Cost: Potting can add to the overall cost of PCB manufacturing. Balancing the benefits of potting with the associated costs is critical for cost-effective production.

Regulatory and Environmental Considerations

Regulatory compliance and environmental considerations play a significant role in the potting process:

- Regulatory Compliance: Ensure that the potting materials and processes comply with industry standards and regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

- Environmental Impact: Consider the environmental impact of the potting materials used. Opt for materials that are environmentally friendly and sustainable.

Future Trends in PCB Potting

Advancements in Potting Materials

Developing new potting materials with enhanced properties is an ongoing trend in the industry. Future materials may offer improved thermal conductivity, flexibility, and environmental resistance, further enhancing the protection and performance of PCBs.

Automation and Precision

Automation in the potting process is becoming increasingly prevalent. Advanced dispensing systems and robotics ensure the precise application of potting materials, reducing the risk of defects and improving consistency.

Integration with IoT and Smart Devices

The demand for reliable and durable PCBs will increase as the Internet of Things (IoT) and smart devices continue to grow. Potting will play a crucial role in ensuring the performance and longevity of these connected devices.

Sustainable Potting Solutions

The industry is moving towards more sustainable potting solutions, including biodegradable and recyclable materials. This shift aims to reduce the environmental impact of electronic waste and promote sustainability.

Conclusion

PCB potting services are essential for enhancing electronic devices’ durability, reliability, and performance across various industries. By providing robust protection against environmental and mechanical stressors, potting ensures that PCBs continue to function optimally in challenging conditions. As advancements in potting materials and technologies continue, the future of PCB potting promises even more significant benefits and opportunities for innovation. Whether in automotive, aerospace, industrial, or consumer applications, potting remains vital in the quest for reliable and long-lasting electronic devices.

For more about choosing the top PCB potting services: a comprehensive guide, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?