Sealing Success: Unveiling the Power of Waterproof Potting Compounds

- Electronic Potting Material Manufacturer

- August 19, 2024

- Automotive potting material manufacturers, Benefits of Potting Electronics, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, Connector Potting Compound, custom automated electronics potting, customize china electronic potting silicone factories, customize china electronic potting silicone manufacturer, customize china electronic potting silicone supplier, deepmaterial epoxy adhesive glue, deepmaterial PCB Potting, deepmaterial potting compound, electrical potting compound, electronic encapsulant potting compounds, electronic epoxy encapsulant potting compounds, Electronic Potting and Encapsulation Resins, electronic potting compound, Electronic Potting Compounds Manufacturer, encapsulant potting compounds, Encapsulants and Potting Compounds Suppliers, epoxy encapsulant potting compounds, epoxy potting compound, epoxy potting compound manufacturers, Flexible Potting Compound, LED Potting Compound, PCB Potting Compound, PCB Potting Compound and Conformal Coating Adhesive, PCB potting compounds, polyurethane potting compound, Waterproof potting compounds

Sealing Success: Unveiling the Power of Waterproof Potting Compounds

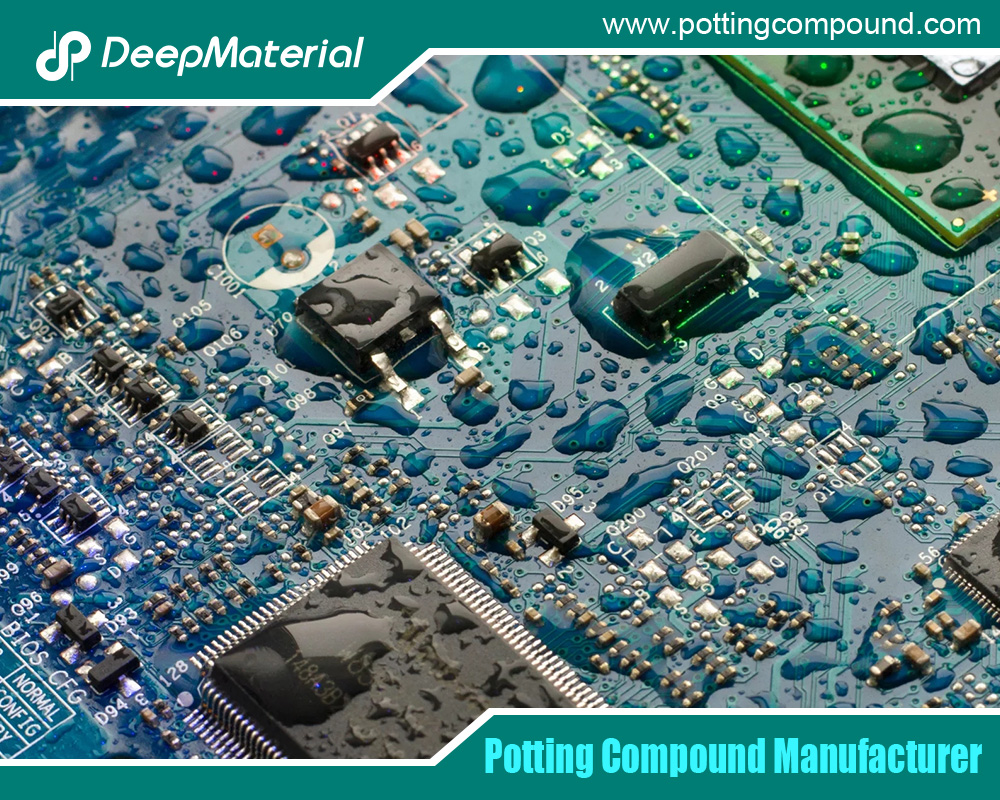

In the ever-evolving world of electronics and electrical engineering, the need to protect sensitive components from harsh environmental conditions has led to significant advancements in materials science. One such advancement is the development of waterproof potting compounds. These materials are crucial in safeguarding electronic assemblies, ensuring longevity and reliable performance even in challenging environments. This article delves into the world of waterproof potting compounds, exploring their composition, applications, benefits, and considerations for use.

What is a Waterproof Potting Compound?

A waterproof potting compound is an encapsulating material that protects electronic components from moisture, dust, vibration, and other environmental hazards. Potting involves filling the electronic assembly with a liquid compound that hardens to form a solid, protective layer. The primary purpose of this compound is to create a barrier against water and other contaminants, thereby enhancing the durability and reliability of the electronic device.

Composition and Types

Waterproof potting compounds come in various formulations, each designed to meet specific requirements. The most common types include:

- Epoxy Compounds:Known for their excellent mechanical and chemical resistance, they are widely used for potting applications. They provide a robust and durable seal that can withstand extreme conditions.

- Polyurethane Compounds:These compounds offer flexibility and are suitable for applications where thermal cycling is a concern. Polyurethanes can absorb mechanical stress, making them ideal for protecting delicate components.

- Silicone Compounds:Silicones are known for their high-temperature resistance and flexibility. They are often used in applications where thermal stability and flexibility are crucial.

- Acrylic Compounds:Acrylic potting compounds are appreciated for their ease of use and fast curing times. They offer good protection against moisture and are suitable for applications requiring quick turnaround.

Applications of Waterproof Potting Compounds

Waterproof potting compounds find applications across various industries, each with unique requirements and challenges. Here are some of the key sectors that benefit from these protective materials:

Automotive Industry

Electronic components in the automotive sector are exposed to harsh conditions, including extreme temperatures, humidity, and mechanical vibrations. Waterproof potting compounds protect sensors, control units, and other electronic assemblies, ensuring their reliable operation throughout the vehicle’s lifespan. These compounds help prevent corrosion and damage caused by water ingress, ultimately enhancing vehicle safety and performance.

Marine and Offshore

Marine and offshore environments are particularly challenging due to constant exposure to saltwater, humidity, and fluctuating temperatures. Waterproof potting compounds protect electronic components in navigation systems, communication devices, and underwater equipment. By providing a robust barrier against moisture, these compounds help extend the life of critical systems used in marine applications.

Consumer Electronics

Consumer electronics like smartphones, wearable devices, and home automation systems require protection from accidental spills, splashes, and humidity. Waterproof potting compounds seal and protect internal components, ensuring these devices continue to function reliably in everyday use. The trend towards water-resistant and waterproof consumer gadgets has driven the demand for effective potting solutions.

Renewable Energy

Solar panels, wind turbines, and other outdoor installations in the renewable energy sector are exposed to the elements. Waterproof potting compounds protect electronic control systems and power conversion units from moisture and environmental contaminants. This protection is crucial for maintaining the efficiency and longevity of renewable energy systems.

Benefits of Using Waterproof Potting Compounds

Using waterproof potting compounds offers numerous benefits that contribute to the reliability and performance of electronic assemblies. Here are some of the key advantages:

Enhanced Protection

The primary benefit of waterproof potting compounds is their ability to protect electronic components from moisture, dust, and other environmental factors. This protection helps prevent corrosion, short circuits, and electrical failures, ensuring the device’s longevity.

Improved Mechanical Strength

Potting compounds add mechanical strength to electronic assemblies, helping to absorb shocks and vibrations. This is particularly important in applications where devices are subject to constant movement or impact, such as in automotive and industrial settings.

Thermal Management

Many waterproof potting compounds are designed to offer thermal conductivity, which helps dissipate heat generated by electronic components. Effective thermal management prevents overheating and ensures the device’s optimal performance.

Chemical Resistance

Electronic components can be exposed to various chemicals in industrial and automotive environments. Waterproof potting compounds protect against chemical exposure, reducing the risk of damage and malfunction.

Customization and Versatility

Waterproof potting compounds are available in various formulations, allowing customization based on specific application requirements. This versatility ensures that the suitable compound can be selected to meet the unique needs of different industries and environments.

Considerations for Using Waterproof Potting Compounds

While waterproof potting compounds offer significant benefits, there are several considerations to keep in mind when selecting and using these materials:

Compatibility

Ensuring that the potting compound is compatible with the materials used in the electronic assembly is essential. Compatibility issues can lead to poor adhesion, reduced effectiveness, and potential damage to components.

Curing Time

Different potting compounds have varying curing times, which can impact production schedules. It is essential to choose a compound that aligns with the desired production timeline and process.

Application Method

The method of applying the potting compound can affect its performance. Proper dispensing equipment and techniques are necessary to ensure even coverage and eliminate air bubbles that could compromise the protective barrier.

Environmental Conditions

The specific environmental conditions to which the electronic assembly will be exposed should guide the selection of the potting compound. Factors such as temperature extremes, humidity levels, and chemical exposure should be considered to ensure optimal performance.

Rework and Repair

In some cases, electronic assemblies may require rework or repair. Choosing a potting compound that allows for easy removal and reapplication is essential. Some compounds are designed for easier removal without damaging the underlying components.

Future Trends and Innovations

The demand for waterproof potting compounds is expected to grow as industries continue to seek ways to enhance the durability and reliability of electronic devices. Several trends and innovations are shaping the future of these protective materials:

Nanotechnology

Nanotechnology is playing a significant role in the development of advanced potting compounds. Nanomaterials can enhance potting compounds’ mechanical, thermal, and chemical properties, providing superior protection for electronic assemblies.

Sustainable and Eco-Friendly Formulations

As environmental concerns continue to rise, there is a growing emphasis on developing sustainable and eco-friendly potting compounds. Manufacturers are exploring the use of bio-based materials and environmentally friendly curing agents to reduce the environmental impact of these products.

Smart Potting Compounds

An emerging trend is the integration of intelligent technologies into potting compounds. These compounds can incorporate sensors and monitoring systems that provide real-time data on the condition of the electronic assembly, enabling proactive maintenance and reducing the risk of failure.

Improved Thermal Management

Innovations in thermal management lead to the development of potting compounds with enhanced heat dissipation properties. These compounds can efficiently manage heat generated by high-power electronic components, improving overall performance and reliability.

Conclusion

Waterproof potting compounds are indispensable in protecting electronic components across various industries. Their ability to safeguard against moisture, dust, vibrations, and chemicals ensures the longevity and reliable performance of electronic assemblies. As technology advances, the development of new and improved potting compounds will play a crucial role in meeting the evolving demands of modern electronics. By understanding the composition, applications, benefits, and considerations of waterproof potting compounds, engineers and manufacturers can make informed decisions to enhance the durability and reliability of their products.

For more about sealing success: unveiling the power of waterproof potting compounds, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?