Epoxy Powder Coating for Electrical Insulation

- Electronic Potting Material Manufacturer

- September 19, 2024

- Acrylic Conformal Coating, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, conformal coating material, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating types, conformal coating waterproof, Electronic Conformal Coating, Epoxy Coating, epoxy coating for electrical insulation, epoxy conformal coating, epoxy potting compound, Epoxy Powder Coating, Epoxy Powder Coating for Electrical, epoxy powder coating for electrical insulation, Industrial Conformal Coating, insulating epoxy coating, pcb conformal coating, polyurethane potting compound, potting compound for electronics, potting compound vs epoxy, powder coating, Silicone Conformal Coating, thermal potting compound, Urethane Conformal Coating, UV Cure Conformal Coating, UV curing potting compound, Waterproof Conformal Coating, waterproof potting compound

Epoxy Powder Coating for Electrical Insulation

Epoxy powder coating is a widely used method for providing electrical insulation, offering several benefits such as durability, chemical resistance, and excellent dielectric properties. This article will delve into the specifics of epoxy powder coating, its application in electrical insulation, the process involved, and its advantages over other methods.

What is Epoxy Powder Coating?

Epoxy powder coating is a thermoset polymer coating applied as a free-flowing, dry powder. Unlike liquid coatings, which require a solvent, powder coatings are applied electrostatically and cured under heat to form a hard, solid layer. Epoxy is famous for powder coatings because of its strong adhesion, chemical resistance, and electrical insulation properties.

The essential components of epoxy powder coatings include:

- Epoxy Resin:The primary component that provides the coating’s mechanical and chemical properties.

- Curing Agents:These chemicals help the epoxy resin harden when heated.

- Pigments and Fillers:These are added to provide color and other specific properties, such as UV resistance.

- Additives:These enhance the coating’s flow, leveling, and surface finish.

Epoxy powder coatings are especially popular in applications requiring high performance and durability, such as electrical insulation.

The Role of Epoxy Powder Coating in Electrical Insulation

Electrical insulation is critical in various industries, especially electronics, automotive, and power generation. Its primary purpose is to prevent the passage of electricity, protect components and users from electrical shocks, and ensure the proper functioning of electrical systems.

Epoxy powder coatings are widely used for electrical insulation due to their superior dielectric properties. They offer the following advantages:

- High Dielectric Strength:Epoxy coatings can withstand high voltages without breaking down, making them ideal for insulating electrical components.

- Thermal Stability:Epoxy coatings maintain their insulating properties even at high temperatures, which is crucial for applications like transformers and motors.

- Chemical Resistance:These coatings resist chemicals, moisture, and other environmental factors that could degrade insulation over time.

- Durability:Epoxy powder coatings are tough and can withstand mechanical stresses without cracking or peeling, ensuring long-lasting insulation.

These properties make epoxy powder coatings preferred for insulating electrical components such as transformers, capacitors, coils, and circuit boards.

The Process of Applying Epoxy Powder Coating for Electrical Insulation

The application of epoxy powder coating involves several key steps, each crucial for ensuring the coating’s effectiveness as an electrical insulator.

- Surface Preparation:

- The surface to be coated must be thoroughly cleaned to remove any contaminants such as oil, grease, dirt, or rust. This is typically done through sandblasting, chemical cleaning, or acid etching.

- The cleaned surface may be pre-treated with a phosphate or chromate coating to enhance adhesion.

- Powder Application:

- The epoxy powder is applied using an electrostatic spray gun. The gun charges the powder particles, which are then attracted to the ground surface of the coated part.

- This method ensures an even distribution of the powder on complex shapes and all coated areas.

- Curing:

- After the powder is applied, the coated part is heated in an oven to a specific temperature, usually between 150°C and 200°C (300°F to 400°F), depending on the formulation of the epoxy.

- The heat causes the epoxy powder to melt, flow, and then chemically react to form a hard, durable coating. This process is called curing, which is essential for developing the coating’s insulating properties.

- Cooling and Inspection:

- After curing, the part is cooled to room temperature. The coating should be smooth, even, and free of defects.

- The coated part is then inspected for thickness, adhesion, and dielectric strength to ensure it meets the required standards for electrical insulation.

Advantages of Epoxy Powder Coating for Electrical Insulation

Epoxy powder coating offers several advantages over traditional liquid coatings and other insulation methods:

- Superior Insulation Properties:

- Epoxy coatings provide excellent electrical insulation with high dielectric strength and low conductivity. This makes them ideal for high-voltage applications.

- Environmental Benefits:

- Unlike liquid coatings, powder coatings do not require solvents, producing fewer volatile organic compounds (VOCs). This makes epoxy powder coatings more environmentally friendly and safer for workers.

- Durability and Resistance:

- Epoxy coatings are highly resistant to mechanical wear, chemicals, moisture, and corrosion. This ensures the insulation remains effective over the long term, even in harsh environments.

- Cost-Effectiveness:

- The powder coating process can be highly automated, reducing labor costs. Additionally, oversprayed powder can be recycled, minimizing waste and reducing material costs.

- Consistency and Quality:

- Powder coatings provide a uniform, smooth finish with consistent thickness, which is difficult to achieve with liquid coatings. This ensures reliable insulation performance across all parts.

- Ease of Application:

- The electrostatic application allows for even coating complex shapes and ensures complete coverage of all areas, reducing the risk of weak spots in the insulation.

Applications of Epoxy Powder Coating in Electrical Insulation

Epoxy powder coatings are used in various applications where electrical insulation is critical. Some of the standard applications include:

- Transformers:

- Transformers are essential components in power distribution systems, and they require robust insulation to prevent electrical faults. Epoxy powder coatings insulate the windings and core, ensuring reliable operation.

- Motors and Generators:

- Electric motors and generators operate under high temperatures and mechanical stresses. Epoxy coatings provide the necessary insulation to prevent short circuits and ensure efficient operation.

- Capacitors:

- Capacitors store electrical energy and require insulation to avoid leakage and to maintain performance. Epoxy powder coatings provide the necessary dielectric strength and stability.

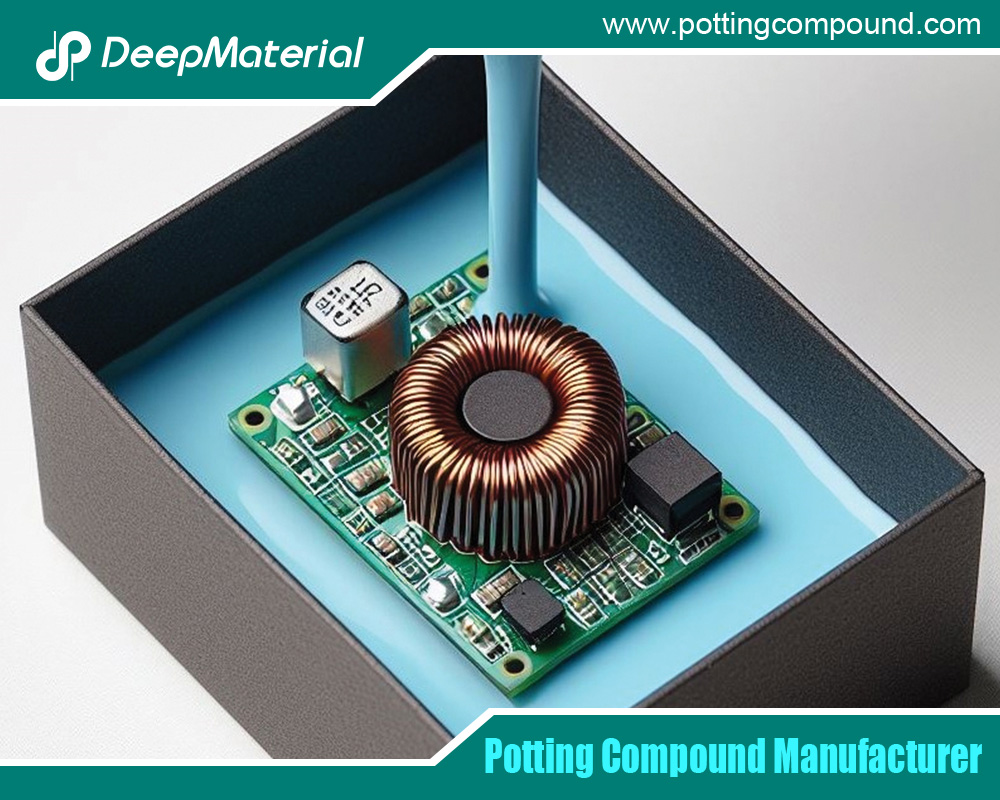

- Printed Circuit Boards (PCBs):

- PCBs are the backbone of electronic devices, requiring insulation to protect the circuitry from electrical interference and damage. Epoxy powder coatings offer a reliable solution for insulating PCBs.

- Coils and Inductors:

- Coils and inductors are used in various electronic devices and require insulation to prevent electrical shorts and maintain functionality. Epoxy coatings provide a durable and practical insulation layer.

- Busbars:

- Busbars are used to distribute electrical power in industrial and commercial settings. They require insulation to prevent electrical faults and ensure safe operation. Epoxy powder coatings are commonly used for this purpose.

Challenges and Considerations in Epoxy Powder Coating for Electrical Insulation

While epoxy powder coating offers numerous benefits for electrical insulation, there are also challenges and considerations to keep in mind:

- Thickness Control:

- Achieving the correct coating thickness is critical for ensuring proper insulation. Too thin a coating may not provide adequate insulation, while too thick a coating can lead to cracking and reduced flexibility.

- Curing Process:

- The curing process must be carefully controlled to ensure the epoxy coating fully cross-links and develops its insulating properties. Improper curing can result in a weak or brittle coating.

- Surface Preparation:

- Proper surface preparation is essential for good adhesion and insulation performance. Any contaminants or imperfections on the surface can lead to coating defects and reduced insulation quality.

- Thermal Cycling:

- In applications where the coated part is subjected to thermal cycling (repeated heating and cooling), the epoxy coating must withstand these temperature changes without cracking or losing its insulating properties.

- Cost Considerations:

- While epoxy powder coating is generally cost-effective, the initial investment in equipment and the cost of high-quality epoxy powders can be significant. However, long-term benefits and reduced maintenance requirements often offset these costs.

Future Trends in Epoxy Powder Coating for Electrical Insulation

The demand for epoxy powder coatings in electrical insulation is expected to grow in the coming years, driven by technological advancements and the increasing need for reliable and durable insulation solutions. Some of the future trends in this field include:

- Nanotechnology:

- Incorporating nanomaterials into epoxy powder coatings could enhance their electrical insulation properties and mechanical performance. For example, adding nanoparticles could improve the coating’s thermal stability and dielectric strength.

- Environmentally Friendly Formulations:

- There is a growing demand for environmentally friendly coatings with low VOCs and reduced environmental impact. Advances in resin chemistry and curing agents are expected to lead to the development of more sustainable epoxy powder coatings.

- Advanced Application Techniques:

- Innovations in application technology, such as robotics and automation, are expected to improve the consistency and efficiency of epoxy powder coating processes. This will enable more precise control over coating thickness and quality.

- Smart Coatings:

- Developing intelligent coatings that can respond to environmental changes or provide real-time data on insulation performance is an exciting area of research. These coatings could offer enhanced protection and monitoring capabilities for critical electrical components.

- Hybrid Coatings:

- Combining epoxy powder coatings with other coatings, such as polyesters or acrylics, could provide a balance of properties tailored to specific applications. Hybrid coatings could offer improved flexibility, UV resistance, and other desirable characteristics.

Conclusion

Epoxy powder coating is a versatile and effective solution for electrical insulation. It offers benefits such as high dielectric strength, durability, and resistance to chemicals and environmental factors. Its application in various industries, from power generation to electronics, highlights its importance in ensuring electrical systems’ safe and reliable operation.

For more about choosing the top epoxy powder coating for electrical insulation, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB