The Potting Material Manufacturer: Essential Players in Electronics Protection

- Electronic Potting Material Manufacturer

- October 15, 2024

- Automotive potting material manufacturers, Benefits of Potting Electronics, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, Connector Potting Compound, custom automated electronics potting, customize china electronic potting silicone factories, customize china electronic potting silicone manufacturer, customize china electronic potting silicone supplier, deepmaterial PCB Potting, deepmaterial potting compound, electrical potting compound, Electronic Encapsulant Potting Compound, electronic encapsulant potting compounds, Electronic Encapsulation in Potting Material Manufacturing, Electronic Epoxy Encapsulant Potting Compound, electronic epoxy encapsulant potting compounds, electronic potting material manufacturer, Epoxy potting material manufacturers, potting material manufacturer, potting material manufacturers, Potting material manufacturers in usa

The Potting Material Manufacturer: Essential Players in Electronics Protection

In today’s rapidly advancing technological landscape, the demand for reliable and efficient electronic devices has never been higher. As devices become more compact and complex, protecting sensitive components from environmental stressors like moisture, dust, chemicals, and mechanical impact is crucial. Potting materials are essential in this context. Potting materials encapsulate electronic components, ensuring their durability and functionality over time. The manufacturers of these materials are critical players in the electronics industry, developing advanced solutions that meet the evolving needs of various sectors, including automotive, aerospace, healthcare, and consumer electronics. This blog post will explore the role of potting material manufacturers, the types of materials they produce, their applications, and future trends in the industry.

What are Potting Materials?

Potting materials are polymeric substances used to encapsulate electronic components, providing a protective layer that enhances their resilience against environmental factors. This process, known as potting, involves filling a mold or housing with liquid potting material that hardens to form a solid, protective barrier around sensitive electronic parts.

Critical Functions of Potting Materials:

- Protection from Moisture:Potting materials create a moisture barrier, preventing corrosion and electrical failures in sensitive components.

- Thermal Management:Many potting materials help dissipate heat generated by electronic components, preventing overheating and prolonging the device’s lifespan.

- Electrical Insulation: Potting materials provide electrical insulation, preventing short circuits and enhancing safety.

- Mechanical Support:Potting’s added rigidity helps protect against mechanical stress and vibration, ensuring components remain securely in place.

Types of Potting Materials

Manufacturers produce various potting materials to meet different application requirements. The choice of material largely depends on the specific environmental conditions the electronics will face. Here are some of the most commonly used potting materials:

Epoxy Resins

- Properties:The material’s properties include excellent adhesion, chemical resistance, and thermal stability.

- Applications:Due to their robustness, these materials are widely used in automotive, aerospace, and industrial electronics.

Polyurethane Resins

- Properties:The material’s properties include flexibility, good moisture and chemical resistance, and excellent thermal cycling capabilities.

- Applications:This material is ideal for applications where vibration and mechanical stress are significant concerns, such as automotive and industrial devices.

Silicone Resins

- Properties:The properties of this material include high flexibility, thermal stability, and resistance to extreme temperatures.

- Applications:This material is commonly used in aerospace and medical devices due to its reliability in high-stress environments.

Acrylic Resins

- Properties:The properties of this material include UV resistance and strong adhesion.

- Applications:This material is suitable for outdoor applications and devices exposed to sunlight, providing adequate protection against environmental elements.

Thermally Conductive Potting Compounds

- Properties:The properties of this material include enhanced thermal management capabilities that facilitate heat dissipation.

- Applications:This material is used in high-power electronics, including LED lighting, power supplies, and battery systems.

The Potting Process: From Application to Curing

The potting process is critical in ensuring that electronic components are adequately protected. Here’s an overview of the typical steps involved in potting:

Preparation

- Cleaning:Components must be cleaned to remove dust, grease, and contaminants that could interfere with adhesion.

- Drying: Ensuring that components are dehydrated is essential to prevent moisture from being trapped in the potting material.

Mold Design and Setup

- Mold Creation:A mold or housing is designed to accommodate the electronic components, ensuring that the potting material can fully encapsulate them.

- Placement:The components are securely placed in the mold before applying potting material.

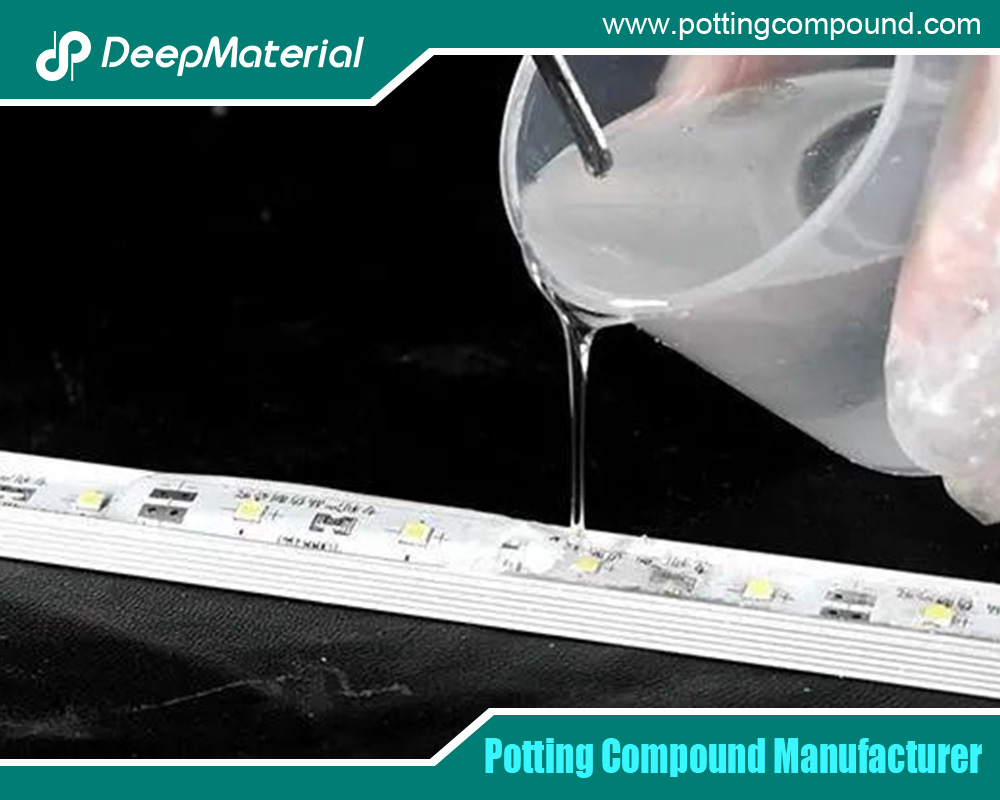

Application of Potting Material

- Pouring/Inserting:The liquid potting material is poured or injected into the mold, filling all voids around the components.

- Avoiding Air Pockets:Care must be taken to eliminate air pockets, which can compromise the protective layer.

Curing

- Curing Process:Depending on the material used, the potting compound is cured at room temperature, heated, or cured with UV light.

- Solidification:This process transforms the liquid material into a solid protective layer, securing the components.

Final Inspection

- Quality Control:Once cured, the encapsulated assembly undergoes inspection to ensure it does not have defects, such as cracks or bubbles.

- Testing:Manufacturers may further test to verify that the potting material meets the required performance specifications.

The Role of Potting Material Manufacturers

Potting material manufacturers play a vital role in the electronics industry by developing innovative materials that meet the growing demands for reliability and performance. Their contributions can be categorized into several key areas:

Material Development

- Research and Innovation:Manufacturers invest in research and development to create new formulations that improve performance, enhance thermal management, and offer better environmental resistance.

- Custom Solutions:They provide tailored solutions to meet specific application needs, ensuring customers receive the most suitable potting material for their projects.

Technical Expertise and Support

- Consultation:Manufacturers offer expert consultation services to help customers select suitable potting materials based on application requirements.

- Technical Support:Ongoing support is provided to troubleshoot issues and ensure proper application and curing processes.

Quality Assurance

- Rigorous Testing:Manufacturers conduct comprehensive testing to ensure that potting materials meet industry standards and customer specifications.

- Certifications:Many manufacturers obtain product certifications, demonstrating compliance with environmental and safety regulations.

Sustainability Efforts

- Eco-Friendly Products:With increasing environmental concerns, manufacturers are focusing on developing eco-friendly potting materials that reduce VOC emissions and are recyclable.

- Sustainable Practices:Many manufacturers are adopting sustainable practices in their production processes to minimize waste and energy consumption.

Future Trends in Potting Material Manufacturing

The potting material manufacturing industry is evolving and driven by technological advancements and market demands. Here are some future trends that are shaping the landscape:

Advancements in Material Science

- Innovative Materials:Research is ongoing into developing intelligent potting materials that adapt to changing environmental conditions, enhancing protection for sensitive components.

- Nanotechnology:Incorporating nanomaterials into potting compounds is expected to enhance performance, providing better thermal management and improved mechanical strength.

Increased Focus on Sustainability

- Green Manufacturing:Manufacturers will likely invest in sustainable production processes, utilizing renewable resources and minimizing waste.

- Recyclable Materials:Developing recyclable potting materials will become increasingly important as environmental regulations become stricter.

Customization and Specialization

- Tailored Solutions:As industries evolve, the demand for specialized potting materials that meet unique application requirements will grow.

- Collaborative Development:Manufacturers may increasingly collaborate with end-users to develop custom solutions that address specific challenges in various industries.

Technological Integration

- Industry 4.0: Integrating innovative manufacturing technologies like IoT and AI will streamline production processes and enhance quality control in potting material manufacturing.

- Automation:Increased automation in the potting process will improve efficiency and reduce the likelihood of human error.

Challenges Facing Potting Material Manufacturers

Despite the promising outlook for the potting material manufacturing industry, there are several challenges that manufacturers must navigate:

Regulatory Compliance

- Stricter Regulations:Manufacturers must stay updated on evolving environmental regulations, ensuring their products meet stringent safety and environmental standards.

Market Competition

- Intense Competition:The potting material market is becoming increasingly competitive, requiring manufacturers to innovate and differentiate their products continuously.

Supply Chain Issues

- Raw Material Availability:Fluctuations in the availability and prices of raw materials can impact production and profitability, necessitating robust supply chain management strategies.

Conclusion

Potting material manufacturers are essential players in the electronics industry, providing critical solutions that enhance the reliability and performance of electronic components. With advancements in material science, a focus on sustainability, and the growing need for specialized solutions, the role of these manufacturers will continue to evolve. As industries increasingly rely on technology, the demand for effective encapsulation will only grow, making potting material manufacturers vital to ensuring the durability and functionality of electronic devices. By understanding the industry’s trends and challenges, manufacturers can position themselves for success in a competitive and dynamic marketplace.

For more about choosing the potting material manufacturer: essential players in electronics protection, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?