Ceramic Potting Compound Manufacturers: Innovating the Future of Electronics Protection

- Electronic Potting Material Manufacturer

- October 29, 2024

- adhesive glue manufacturer, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting compound, Connector Potting Compound, deepmaterial potting compound, electrical potting compound, Electronic Encapsulant Potting Compound, Electronic Epoxy Encapsulant Potting Compound, Electronic Epoxy Potting Compound, electronic potting compound, Electronic Potting Compound Market, Encapsulant Potting Compound, Encapsulants and Potting Compounds Suppliers, Epoxy Encapsulant Potting Compound, epoxy potting compound, Flexible Potting Compound, industrial adhesive suppliers, Industrial Conformal Coating, pcb conformal coating, potting compound, Silicone Potting Compound, silicone potting compound for electronics, Urethane Conformal Coating, UV Cure Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating

Ceramic Potting Compound Manufacturers: Innovating the Future of Electronics Protection

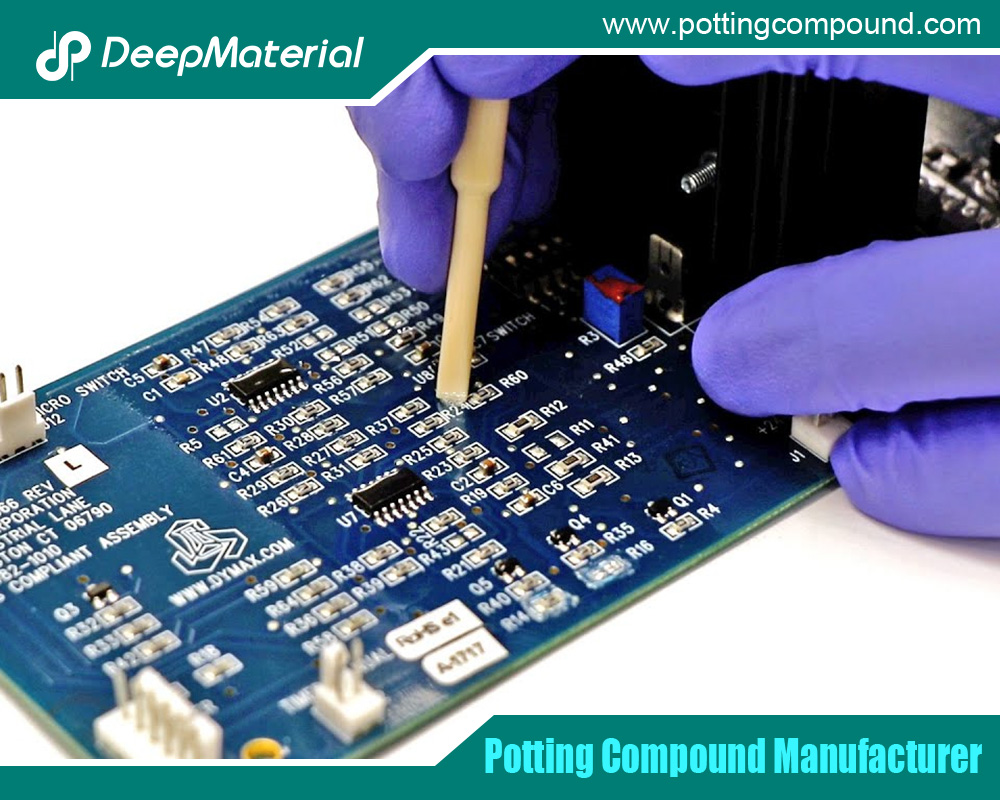

Ceramic potting compounds have become essential materials in the electronics industry, providing unparalleled protection for sensitive electronic components. As the demand for reliable and durable electronic devices grows, manufacturers of ceramic potting compounds are stepping up to meet the challenge. These specialized compounds offer high thermal stability, excellent electrical insulation, and resistance to harsh environmental conditions. This blog post explores the role of ceramic potting compound manufacturers, the types of ceramic potting compounds available, their applications, market trends, challenges, and the future outlook of this critical industry.

Understanding Ceramic Potting Compounds

Ceramic potting compounds are specialized materials designed to encapsulate electronic components and provide protection against various environmental factors. They are typically composed of inorganic materials, offering high-temperature resistance and durability. Unlike traditional organic potting compounds, ceramic-based formulations provide unique advantages that make them suitable for specific applications.

Critical Properties of Ceramic Potting Compounds:

- High Thermal Stability:Ceramic potting compounds can withstand extreme temperatures without degrading, making them ideal for high-heat applications.

- Excellent Electrical Insulation: These compounds provide superior electrical insulation, protecting components from short circuits and electrical failures.

- Chemical Resistance:Ceramic compounds exhibit excellent resistance to chemicals, oils, and solvents, ensuring longevity in harsh environments.

- Mechanical Strength:The inherent strength of ceramic materials provides mechanical protection against vibrations, shocks, and impacts.

Types of Ceramic Potting Compounds

Ceramic potting compound manufacturers produce various formulations to cater to diverse application requirements. Some common types include:

Epoxy Ceramic Potting Compounds

- Description:These compounds blend epoxy resins and ceramic fillers, providing a balance of flexibility and rigidity.

- Applications:These materials suit automotive electronics, aerospace components, and high-power devices.

Polyurethane Ceramic Potting Compounds

- Description:By combining polyurethane with ceramic materials, manufacturers create compounds that offer flexibility and resistance to thermal cycling.

- Applications: These are ideal for applications requiring mechanical flexibility, such as wearable electronics.

Silicone Ceramic Potting Compounds

- Description:Silicone-based ceramic potting compounds provide excellent high-temperature stability and flexibility.

- Applications:These materials are widely used in aerospace, automotive, and industrial applications.

Thermosetting Ceramic Potting Compounds

- Description:These compounds cure to form a rigid structure, providing high mechanical strength and thermal stability.

- Applications:These materials are suitable for high-reliability applications in harsh environments.

Key Applications of Ceramic Potting Compounds

Ceramic potting compounds serve a variety of industries, providing critical protection for electronic components. Here are some key sectors where ceramic potting compounds are commonly used:

Aerospace Industry

- Avionics Systems:Ceramic potting compounds are essential for encapsulating avionics systems, ensuring protection from extreme temperatures and mechanical stress.

- Communication Equipment: Used in satellite communication systems and radar equipment, providing durability and reliability.

Automotive Industry

- Engine Control Units (ECUs): Ceramic potting compounds protect ECUs from high temperatures, moisture, and vibrations.

- Sensors:These are used to encapsulate sensors that operate in harsh environments, ensuring accuracy and longevity.

Industrial Applications

- Control Systems:Potting compounds protect electronic control systems in machinery and equipment from environmental stressors.

- Robotics:These materials are used in robotics applications to enhance the durability of electronic components.

Consumer Electronics

- Smartphones and Tablets:Ceramic potting compounds improve the reliability and durability of smartphones and tablets, protecting them from moisture and impact.

- Wearable Devices: Widely used in wearable technology to ensure the performance and longevity of electronic components.

Medical Devices

- Diagnostic Equipment:Protects sensitive electronics in diagnostic and monitoring equipment, ensuring reliable operation in clinical settings.

- Implantable Devices:Ceramic potting compounds are developed to meet biocompatibility standards for healthcare applications.

Market Trends Influencing the Ceramic Potting Compound Industry

The ceramic potting compound market is shaped by several key trends that influence product development and consumer demand.

Technological Advancements

- Innovative Materials:Developing intelligent ceramic potting compounds that adapt to changing environmental conditions is gaining traction, enhancing protection for sensitive components.

- Nanotechnology:Incorporating nanomaterials into ceramic formulations is expected to improve performance, providing better thermal management and enhanced mechanical strength.

Sustainability Initiatives

- Eco-Friendly Formulations:Increasing environmental concerns drive manufacturers to develop eco-friendly ceramic potting compounds that minimize VOC emissions and utilize renewable resources.

- Sustainable Manufacturing Practices:Many manufacturers adopt sustainable practices in their production processes, focusing on waste reduction and energy efficiency.

Growing Demand for Miniaturization

- Compact Electronics: The trend towards miniaturization in electronics is increasing the need for advanced ceramic potting compounds that can effectively protect smaller footprints.

- High-Density Assemblies:Potting compounds must accommodate electronic assemblies’ growing complexity and density.

Regulatory Compliance

- Stricter Regulations:Manufacturers must comply with increasingly stringent regulations regarding chemical safety and environmental impact, significantly influencing their product formulations and marketing strategies.

Challenges Facing Ceramic Potting Compound Manufacturers

While the ceramic potting compound market is growing, manufacturers face several challenges:

Raw Material Availability

- Supply Chain Disruptions: Fluctuations in the availability and prices of raw materials can impact production and profitability, necessitating robust supply chain management strategies.

Competition

- Market Saturation:The potting compound market is becoming increasingly competitive, requiring manufacturers to innovate and differentiate their products continuously.

Technological Complexity

- Keeping Up with Advancements: Rapid technological advancements demand continuous investment in research and development to create high-performance potting compounds.

Future Outlook of the Ceramic Potting Compound Market

The ceramic potting compound market is poised for growth in the coming years, driven by emerging technologies and increasing demand for reliable protective solutions. Here are some key factors influencing the future outlook:

Expanding End-Use Industries

- Growth in Automotive and Aerospace:The increasing demand for electric vehicles (EVs) and advanced aerospace technologies will drive the need for high-performance ceramic potting compounds.

- Healthcare Innovations:The growth of the medical device industry will further boost demand for reliable encapsulation solutions.

Innovations in Product Development

- Customized Solutions:Manufacturers will likely focus on developing tailored ceramic potting compounds that meet specific application needs, enhancing performance and reliability.

- Advancements in Formulation Technology:Continuous research will lead to the creation of advanced formulations with improved properties, addressing the evolving needs of various industries.

Sustainability Focus

- Eco-Friendly Products:As regulations tighten, developing sustainable ceramic potting compounds that minimize environmental impact will become increasingly important.

- Circular Economy Initiatives:Manufacturers may adopt circular economy practices, focusing on recycling and reusing potting materials to reduce waste.

Conclusion

Ceramic potting compound manufacturers are crucial players in the electronics industry, providing essential protective solutions for sensitive electronic components. With their unique properties, ceramic potting compounds offer high thermal stability, excellent electrical insulation, and resistance to harsh environmental conditions. As the demand for reliable and durable electronic devices continues to grow, the ceramic potting compound market is expected to experience significant growth. Manufacturers will need to navigate challenges such as raw material availability and competition while continuing to innovate and develop high-performance ceramic potting compounds that meet the evolving needs of various industries. The future of this market looks promising, driven by technological advancements, sustainability initiatives, and a growing emphasis on the durability and reliability of electronic devices.

For more about choosing the Top Ceramic Potting Compound Manufacturers: Innovating the Future of Electronics Protection, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?