The Epoxy Potting Process: A Comprehensive Guide to Protecting Electronic Components

- Electronic Potting Material Manufacturer

- November 25, 2024

- adhesive glue manufacturer, conformal coating for electronics, conformal coating for pcb, conformal coating pcb, conformal coating silicone, conformal coating spray, conformal coating types, conformal coating waterproof, Connector Potting Compound, electronic potting compound, epoxy potting compound, Epoxy Potting Process, Epoxy Potting Process China OEM, Epoxy Potting Process China Wholesale, Epoxy Potting Process Factory Hotsale, Epoxy Potting Process Factory OEM, Epoxy Potting Process Factory Wholesale, Epoxy Potting Process Hotsale, Epoxy Potting Process Manufacturer, Epoxy Potting Process OEM, Epoxy Potting Process Supplier, Epoxy Potting Process Wholesale, Flexible Potting Compound, industrial adhesive suppliers, LED Potting Compound, PCB Potting Compound, polyurethane potting compound, Silicone Potting Compound, UV Cure Potting Compound, waterproof potting compound

The Epoxy Potting Process: A Comprehensive Guide to Protecting Electronic Components

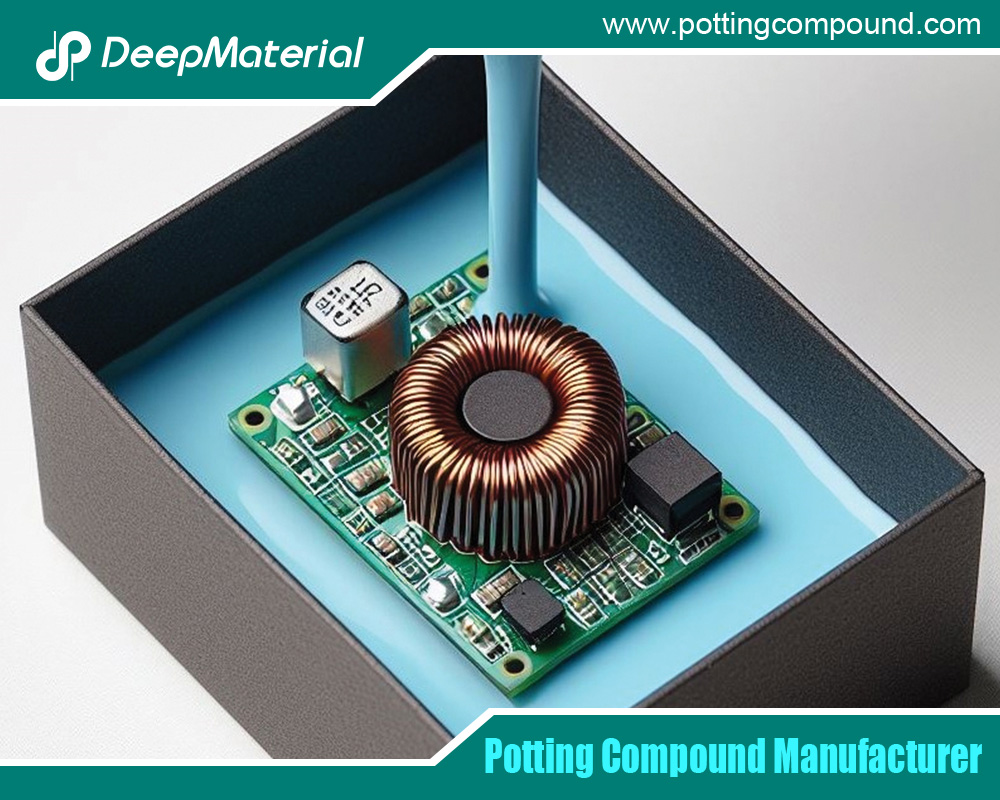

In the realm of electronics, the durability and reliability of components are paramount. As devices become more compact and are exposed to increasingly harsh environments, manufacturers must seek practical solutions to safeguard sensitive electronic parts. One of the most effective methods for achieving this is through the epoxy potting process. This technique encapsulates electronic components in a protective epoxy resin, enhancing their performance and lifespan. This blog post will explore the epoxy potting process in detail, covering its significance, the materials used, application techniques, benefits, challenges, and future trends.

Understanding the Epoxy Potting Process

Epoxy potting involves encasing electronic components in epoxy resin, a thermosetting polymer known for its excellent adhesive properties, thermal stability, and electrical insulation capabilities. The potting process protects components from environmental hazards and enhances their mechanical strength and electrical performance.

Critical Components of the Epoxy Potting Process

- Epoxy Resin: The primary material used for potting, chosen for its durability and protective properties.

- Hardener: A curing agent mixed with epoxy resin to initiate the hardening process.

- Component Preparation: The steps taken to prepare electronic components for potting, ensuring optimal adhesion and performance.

- Application Techniques: Methods employed to apply the epoxy resin effectively.

- Curing Process: The procedures followed to harden the epoxy resin and ensure a solid encapsulation around the components.

Why Use Epoxy for Potting Electronics?

Epoxy is favored for potting electronics due to its numerous benefits, which include:

Environmental Protection

Epoxy potting provides a robust barrier against environmental factors that could damage electronic components, such as:

- Moisture Ingress: Prevents corrosion and short circuits caused by water exposure.

- Dust and Contaminants: Shields sensitive parts from debris and contaminants that could impair functionality.

- UV Radiation: Protects against degradation due to ultraviolet light exposure.

Mechanical Strength

Encapsulating components with epoxy resin enhances their mechanical integrity, providing:

- Vibration Resistance: Protects against damage from vibrations, especially in automotive and aerospace applications.

- Impact Resistance: Safeguards components from physical shocks and impacts during use.

Electrical Insulation

Epoxy resin’s high dielectric strength helps prevent electrical failures by providing:

- Reduced Short Circuits Risk: Minimizes electrical failure chancesdue to moisture or contamination.

- Improved Signal Integrity: Ensures consistent performance in sensitive electronic systems.

Longevity and Reliability

Using epoxy for potting can extend the lifespan of electronic components, resulting in:

- Fewer Failures: Reduces the need for repairs and replacements, leading to lower maintenance costs.

- Enhanced Performance: Ensures that components operate reliably over extended periods.

The Epoxy Potting Process: Step-by-Step Guide

The epoxy potting process consists of several critical steps, each essential for achieving optimal results. Here’s a detailed breakdown:

Step 1: Preparation

Proper preparation is critical to a successful potting process. This includes:

- Cleaning the Components: Thoroughly clean the electronic components to remove dirt, dust, or grease. This ensures proper adhesion of the epoxy resin.

- Drying: Ensure the components are dehydrated, as moisture can interfere with curing.

Step 2: Selecting the Epoxy Resin

Choosing the suitable epoxy resin is crucial for achieving the desired performance characteristics. Key considerations include:

- Material Properties: Select epoxy resins suitable for the application based on viscosity, curing time, and thermal stability.

- Compatibility: To prevent adverse reactions, ensure that the epoxy resin is compatible with the materials used in the electronic components.

Step 3: Mixing the Epoxy Resin

Mixing the epoxy resin with the hardener is a critical step in the potting process:

- Proportions: Follow the manufacturer’s guidelines for the correct mixing ratio to ensure optimal curing and performance.

- Mixing Technique: Use a clean container thoroughly to achieve a uniform consistency.

Step 4: Application of the Epoxy Resin

The method of applying epoxy resin can vary depending on the specific requirements of the components:

- Manual Application: This method is suitable for small batches or specialized components. It involves pouring or dispensing the epoxy resin by hand.

- Automated Dispensing: This is ideal for large-scale production where precise dispensing of the epoxy resin is required. Automated systems can use various methods, such as syringe dispensing or pressure pots.

Step 5: Curing the Epoxy Resin

Curing hardens the epoxy resin to form a solid encapsulation around the components. This can be achieved through various methods:

- Room Temperature Curing: Some epoxy resins cure at ambient temperatures, making this method convenient and energy-efficient.

- Heat Curing: Applying heat can accelerate the curing process and enhance the properties of the epoxy resin, resulting in a stronger bond.

- UV Curing: Certain epoxy formulations can be cured using ultraviolet light, providing quick curing times and high-performance characteristics.

After completing the potting process, conducting quality control checks is crucial to ensure the components meet the required specifications. This may include:

- Visual Inspection: Checking for any defects or irregularities in the epoxy encapsulation.

- Electrical Testing: Verifying the electrical performance of the encapsulated components to ensure they function as intended.

Benefits of the Epoxy Potting Process

The epoxy potting process offers numerous advantages, including:

- Enhanced Durability: Protects components from environmental hazards, ensuring long-lasting performance.

- Improved Reliability: Reduces the likelihood of component failures, leading to more excellent system reliability.

- Cost Savings: Lowers maintenance and repair costs by minimizing the need for replacements.

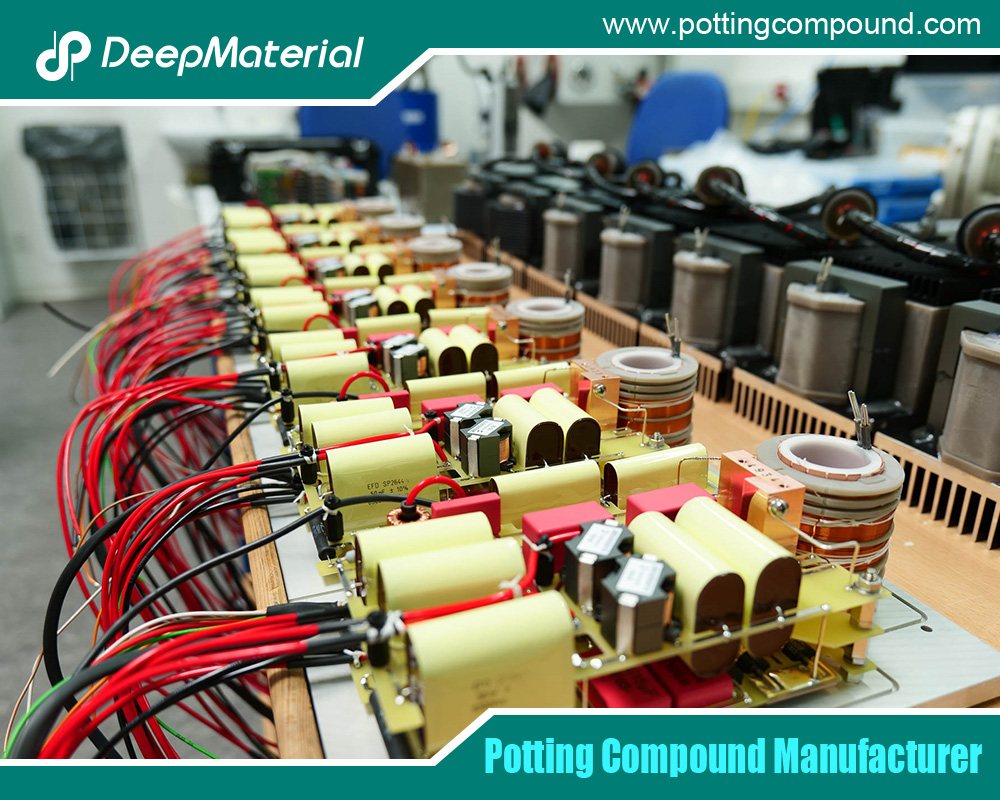

- Versatility: Suitable for various applications across multiple industries, including automotive, aerospace, medical devices, and consumer electronics.

Challenges in the Epoxy Potting Process

While epoxy potting offers significant advantages, there are also challenges that manufacturers must consider:

Material Selection

Choosing the appropriate epoxy resin is critical, as different materials exhibit varying properties. Factors to consider include:

- Curing Time: Longer curing times can slow production, while quick-curing materials may compromise performance.

- Thermal Stability: Selecting a resin that can withstand the operating temperatures of the application is essential.

Application Techniques

Applying epoxy resin can be challenging, particularly for complex component designs. Issues may arise from:

- Air Entrapment: Care must be taken to avoid trapping air bubbles during application, which can compromise the protective barrier.

- Inconsistent Coating: Ensuring a uniform application is essential for adequate protection.

Curing Conditions

Achieving the right curing conditions is crucial for optimal performance. Factors include:

- Temperature and Humidity: Fluctuations in these conditions can affect curing, leading to inconsistent results.

- Time Constraints: Balancing the need for quick production with the required curing times can be challenging.

Innovations and Future Trends in Epoxy Potting

As technology advances, so does the use of epoxy in potting applications. Some emerging trends include:

Eco-Friendly Epoxy Resins

With increasing environmental concerns, there is a growing demand for eco-friendly epoxy resins. Manufacturers are increasingly seeking:

- Biobased Epoxy Resins: Made from renewable resources to reduce environmental impact.

- Low-VOC Formulations: To improve workplace safety and reduce harmful emissions.

Smart Materials

Innovative materials that can respond to environmental changes are being developed. These innovative epoxy solutions may include:

- Self-healing Epoxy Resins: Capable of repairing minor damage automatically, enhancing longevity.

- Temperature-Sensitive Resins: These can adapt to temperature fluctuations, providing better protection.

Advanced Automation

The use of automation and robotics in the potting process is becoming more prevalent, offering several advantages:

- Increased Precision: Automated systems ensure consistent application and reduce the risk of human error.

- Higher Throughput: Automation allows for faster production rates, improving overall efficiency.

Conclusion

The epoxy potting process is vital for protecting electronic components in various applications. Manufacturers can safeguard against environmental hazards, mechanical stress, and electrical failures by encapsulating components in epoxy resin. While challenges exist, advancements in materials and technology continue to improve the effectiveness of the potting process.

For more about choosing the Top Epoxy Potting Process: A Comprehensive Guide to Protecting Electronic Components, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?