Understanding PCB Potting Materials: A Comprehensive Guide for Manufacturers

- Electronic Potting Material Manufacturer

- December 9, 2024

- Acrylic Conformal Coating, Connector Potting Compound, Electronic Conformal Coating, electronic potting compound, epoxy conformal coating, epoxy potting compound, Flexible Potting Compound, Industrial Conformal Coating, LED Potting Compound, pcb conformal coating, PCB Potting Compound, PCB Potting Material, PCB potting material china hotsale, PCB potting material china OEM, PCB potting material china wholesale, PCB potting material factory hotsale, PCB potting material factory OEM, PCB potting material factory wholesale, polyurethane potting compound, Silicone Conformal Coating, Silicone Potting Compound, Urethane Conformal Coating, UV Cure Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating, waterproof potting compound

Understanding PCB Potting Materials: A Comprehensive Guide for Manufacturers

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the essential pathways for electrical connections. The demand for reliable and durable PCBs has grown exponentially as technology advances. One critical aspect of ensuring the longevity and performance of these boards is the selection of appropriate potting materials. This article will delve into the essentials of PCB potting materials, emphasizing the role of suppliers in providing high-quality options for manufacturers. We will explore various types of potting materials, their applications, and the selection criteria for choosing a PCB potting material supplier.

What is PCB Potting?

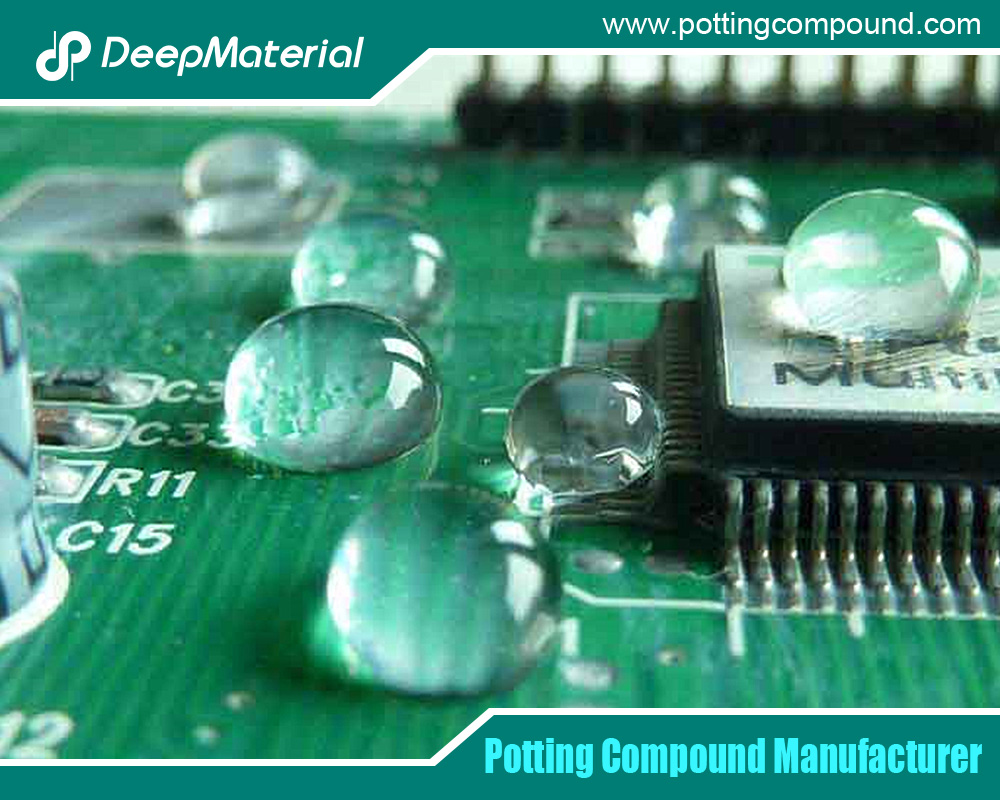

PCB potting involves encasing electronic components within a protective material to enhance their durability and reliability. Potting serves multiple purposes, including:

- Protection Against Environmental Factors:Potting materials shield components from moisture, dust, chemicals, and extreme temperatures.

- Mechanical Stability: The process enhances mechanical strength and helps protect against vibrations and shocks.

- Electrical Insulation:Potting materials provide electrical insulation, preventing short circuits and ensuring safe operation.

- Thermal Management: They aid in heat dissipation, helping to manage the thermal characteristics of sensitive components.

Types of Potting Materials

The choice of potting material is crucial for optimizing PCB performance and lifespan. Various materials are commonly used in potting applications, each with distinct characteristics and benefits.

1. Epoxy Resins

Description: Epoxy resins are famous for their excellent adhesion, chemical resistance, and mechanical properties.

Advantages:

- High thermal stability

- Low shrinkage during curing

- Excellent electrical insulation properties

Applications: Ideal for harsh environments, including automotive and aerospace electronics.

2. Polyurethane Resins

Description: Polyurethane potting materials offer flexibility and durability, making them suitable for various applications.

Advantages:

- Good resistance to moisture and UV light

- Flexible, allowing for thermal expansion without cracking

- Easy to process and apply

Applications: Commonly used in consumer electronics and appliances.

3. Silicone Resins

Description: Silicone potting materials provide exceptional temperature resistance and flexibility.

Advantages:

- Wide operating temperature range

- Excellent electrical insulation

- Good chemical resistance

Applications: Suitable for applications in high-temperature environments, such as LED lighting.

4. Polyester Resins

Description: Polyester resins are less commonly used but offer cost-effective solutions for specific applications.

Advantages:

- Good balance of strength and flexibility

- Cost-effective compared to other resin types

Applications: Used in less demanding applications where high performance is not critical.

Factors to Consider When Selecting Potting Materials

Manufacturers must consider several key factors when choosing potting materials for PCB applications to ensure optimal performance.

Environmental Resistance

Evaluate the environmental conditions the PCB will encounter, including:

- Humidity levels

- Temperature fluctuations

- Exposure to chemicals or solvents

Mechanical Properties

Assess the mechanical stresses the PCB will experience, including:

- Vibration and shock resistance

- Flexibility or rigidity required

Thermal Conductivity

Consider the thermal properties of the potting material:

- Ability to dissipate heat generated by electronic components

- Thermal expansion characteristics

Electrical Insulation

- Ensure the chosen material provides adequate electrical insulation to prevent short circuits and enhance safety.

Curing Time

Take into account the curing time required for the potting material:

- Faster curing times can improve production efficiency

- Ensure compatibility with existing manufacturing processes

Choosing the Right PCB Potting Material Supplier

Selecting a reliable PCB potting material supplier ensures access to high-quality materials and expert support. Here are key considerations when evaluating potential suppliers:

Experience and Reputation

Research the supplier’s experience in the industry:

- Years of operation

- Customer testimonials and reviews

- Recognition in the industry

Product Range

Evaluate the supplier’s range of potting materials:

- Availability of various resin types

- Custom formulations to meet specific requirements

Technical Support

Assess the level of technical support offered by the supplier:

- Availability of engineering expertise

- Assistance with material selection and application techniques

Quality Assurance

Inquire about the supplier’s quality control processes:

- Certifications and compliance with industry standards

- Testing and validation of potting materials

Logistics and Delivery

Consider the supplier’s logistics capabilities:

- Timeliness of delivery

- Inventory management and order fulfillment

Applications of PCB Potting Materials

Potting materials are utilized across various industries, each requiring specific properties to ensure reliability and performance. Here are some notable applications:

Automotive Electronics

- Potting materials protect components from harsh automotive environments, including moisture and vibrations.

Aerospace Applications

- In aerospace, potting materials safeguard sensitive electronics against extreme temperatures and pressure changes.

Consumer Electronics

- Potting enhances durability and reliability in consumer products, ensuring a longer product life.

Medical Devices

- Potting materials protect sensitive medical electronics from contaminants and enhance patient safety.

Industrial Equipment

- Potting is vital for industrial control systems, protecting against dust, moisture, and chemical exposure.

Future Trends in PCB Potting Materials

The field of PCB potting materials is continually evolving and influenced by technological advancements and changing industry demands. Key trends include:

Sustainable Materials

- Growing interest in eco-friendly potting materials, such as bio-based resins, to reduce environmental impact.

Advanced Formulations

- Development of high-performance potting materials with enhanced properties for demanding applications.

Integration with Smart Technologies

- Innovative potting materials can be used to monitor the condition of electronic components and provide real-time feedback.

Automation in Potting Processes

- Increasing use of automated potting techniques to enhance efficiency and precision in manufacturing.

Benefits of Using PCB Potting Materials

Utilizing potting materials in PCB manufacturing provides several key advantages that enhance product performance and reliability. Here are some notable benefits:

- Enhanced Durability: Potting materials protect against physical damage from vibrations, shocks, and impacts, extending the lifespan of electronic components.

- Moisture and Corrosion Resistance: They create a waterproof barrier, preventing moisture ingress and reducing the risk of corrosion that can compromise functionality.

- Improved Thermal Management:Potting materials assist in heat dissipation, preventing overheating and ensuring optimal electronic device operation.

- Electrical Safety: Potting materials help prevent short circuits by providing superior insulation, enhancing the overall safety of electronic systems.

- Noise Reduction: Potting materials can dampen vibrations, helping to minimize operational noise and making devices quieter and more efficient.

Best Practices for Potting Application

To ensure optimal performance and effectiveness of potting materials in PCBs, manufacturers should follow these best practices:

- Surface Preparation:Clean the surfaces of the components to be potted thoroughly to promote adhesion and prevent contamination.

- Proper Mixing:Adhere to the manufacturer’s instructions for mixing potting compounds to ensure uniformity and effectiveness.

- Controlled Environment: Apply potting materials in a controlled environment to prevent contamination and ensure consistent curing conditions.

- Testing for Compatibility:Conduct compatibility tests between potting materials and PCB components to avoid adverse reactions that could affect performance.

- Quality Assurance:Implement stringent quality control measures to verify the consistency and reliability of the potting process, ensuring long-term performance.

Conclusion

The selection of appropriate PCB potting materials is essential for ensuring electronic components’ reliability, durability, and performance. Manufacturers must carefully evaluate the types of materials available, their properties, and the specific needs of their applications. Choosing the right PCB potting material supplier is critical for accessing high-quality products and technical support. As technology advances, staying informed about the latest trends and innovations in potting materials will help manufacturers meet the evolving demands of the electronics industry. By prioritizing quality and performance, manufacturers can enhance their PCBs’ longevity and contribute to their products’ overall success.

For more about understanding PCB potting materials: a comprehensive guide for manufacturers, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?