Understanding Circuit Board Potting Compounds: Essential Protection for Electronics

- Electronic Potting Material Manufacturer

- December 13, 2024

- Automotive potting material manufacturers, Benefits of Potting Electronics, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting compound, circuit board potting compound china hotsale, circuit board potting compound china OEM, circuit board potting compound china wholesale, circuit board potting compound factory hotsale, circuit board potting compound factory OEM, circuit board potting compound factory wholesale, circuit board potting compound hotsale, circuit board potting compound wholesale, Connector Potting Compound, custom automated electronics potting, deepmaterial potting compound, electric motor potting compound, electric motor potting compound china hotsale, electrical potting compound, Electronic Encapsulant Potting Compound, Electronic Epoxy Encapsulant Potting Compound, potting compound

Understanding Circuit Board Potting Compounds: Essential Protection for Electronics

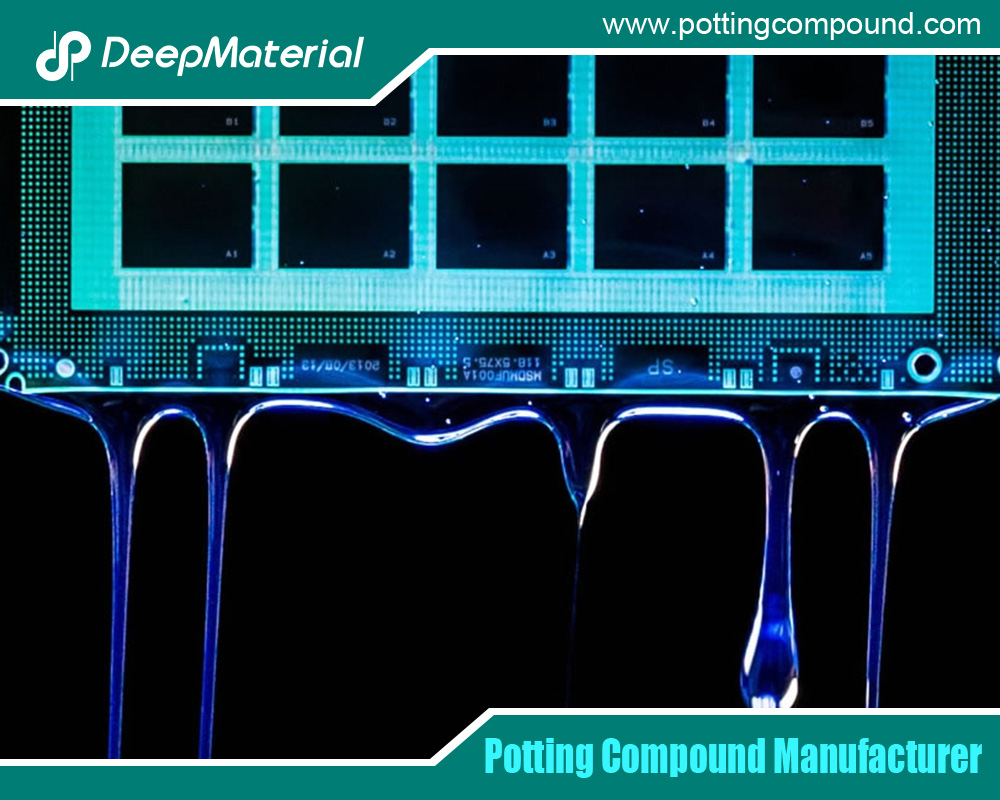

In the realm of electronics, circuit boards’ reliability and longevity are paramount. As these boards are the backbone of virtually all electronic devices, protecting them from environmental factors is crucial. Circuit board potting compounds provide a protective barrier that enhances durability, ensuring that devices can withstand various conditions. This article explores the importance of potting compounds, their types, applications, and innovations that shape their future in electronics.

Core Advantages of Circuit Board Potting Compounds

Circuit board potting compounds offer numerous advantages that significantly contribute to the reliability of electronic devices. Here are some core benefits:

- Moisture Resistance: Prevents corrosion and damage from humidity and water exposure.

- Thermal Stability: Assists in heat dissipation, protecting components from overheating.

- Mechanical Protection: Shields circuit boards from impacts, vibrations, and physical stress.

- Electrical Insulation: Enhances dielectric strength, reducing the risk of short circuits.

- Chemical Resistance:Protects against exposure to harmful chemicals and solvents.

Major Types of Potting Compounds and Their Unique Properties

Potting compounds come in various formulations, each suited for specific applications. Here are the most common types and their unique properties:

Epoxy Compounds

- Characteristics: High strength, excellent moisture resistance, and good thermal stability.

- Applications: Ideal for industrial applications and harsh environments.

Silicone Compounds

- Characteristics:Flexibility, excellent temperature tolerance, and resistance to extreme conditions.

- Applications:Commonly used in automotive and aerospace industries.

Polyurethane Compounds

- Characteristics: Good impact resistance and flexibility, more accessible to rework.

- Applications: Often used in consumer electronics and less harsh environments.

Acrylic Compounds

- Characteristics: Fast curing, excellent UV resistance.

- Applications: Suitable for outdoor applications and devices exposed to sunlight.

Choosing the Right Potting Compound: Essential Factors to Consider

Selecting the appropriate potting compound for a circuit board involves careful consideration of various factors:

Environmental Conditions

- Temperature fluctuations

- Moisture exposure

- Chemical exposure

Physical Properties

- Hardness and flexibility

- Adhesion strength to substrates

- Thermal conductivity

Reworkability

- Ease of removal for future repairs

- Ability to rework without damaging the circuit board

The Potting Process: Steps to Ensure Effective Circuit Board Protection

The application of potting compounds is a critical process that must be executed precisely. Here are the key steps:

Surface Preparation

- Clean the circuit board to remove dust, oils, and contaminants.

Application

- Dispense the potting compound using appropriate equipment to ensure even coverage.

Curing

- Allow the compound to cure according to the manufacturer’s instructions, which can vary based on the type of compound.

Testing

- Conduct functionality tests post-curing to ensure the integrity of the circuit board remains intact.

Industry Applications: Where and Why Potting Compounds are Essential

Potting compounds are utilized across various industries due to their protective qualities. Key applications include:

Automotive Electronics

- Protection for sensors and control modules from vibrations and extreme temperatures.

Aerospace and Defense

- They are safeguarding sensitive avionics and electronics from harsh environmental conditions.

Medical Devices

- It is enhancing the reliability of equipment subjected to sterilization and frequent use.

Consumer Electronics

- Increasing the durability and waterproofing of everyday devices like smartphones and wearables.

Techniques for Achieving Optimal Potting Results in Electronics

Achieving optimal results with potting compounds requires careful attention to detail. Here are some effective techniques:

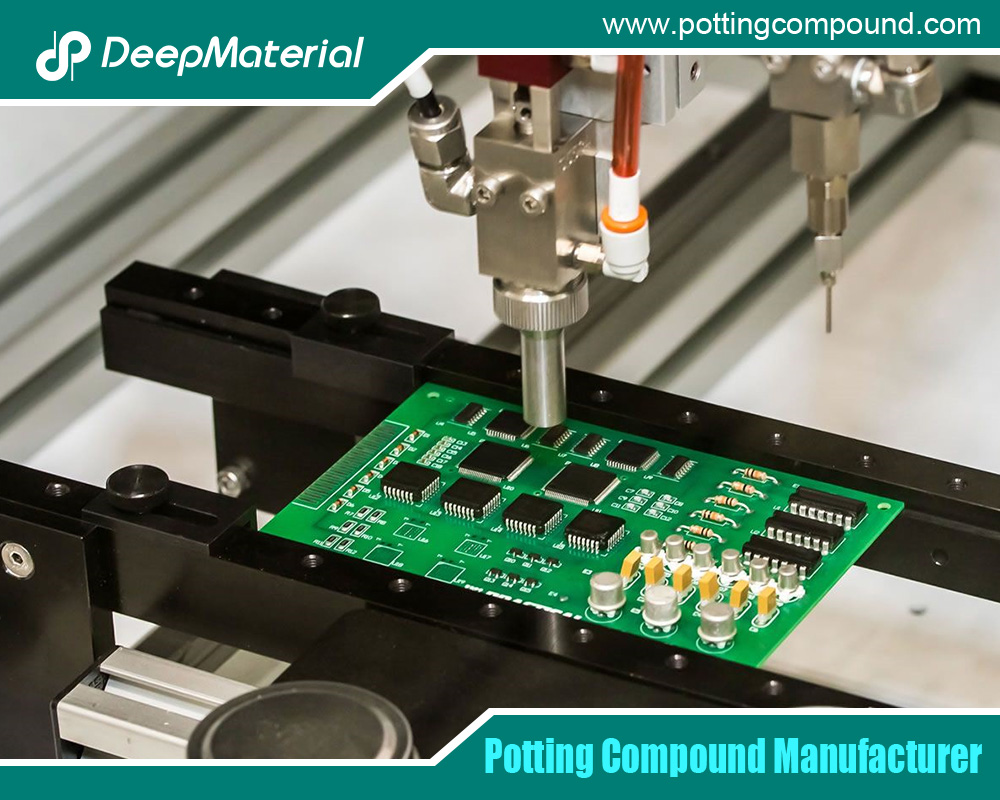

Controlled Dispensing

- Automated dispensing systems for consistent application and minimal waste.

De-aeration Processes

- Employ vacuum or de-aeration techniques to eliminate air bubbles before curing.

Cure Time Management

- Monitor and control cure times to prevent overheating and ensure adequate bonding.

Thermal, Chemical, and Physical Properties of Potting Compounds

Understanding the properties of potting compounds helps select the suitable material for specific applications. Key properties include:

Thermal Conductivity

- Necessary for heat dissipation in high-performance electronics.

Chemical Resistance

- Ability to withstand exposure to solvents, oils, and other chemicals.

Mechanical Strength

- The toughness of the potting compound impacts its protective capabilities.

Tackling Common Potting Issues: Tips for Optimal Application

Common challenges can arise during the potting process, but they can be addressed effectively. Here are some issues and solutions:

Air Bubbles in the Compound

- Cause: Trapped air during application.

- Solution:Use vacuum techniques or low-viscosity compounds to reduce air entrapment.

Excessive Heat Generation

- Cause: High exothermic reactions during curing.

- Solution: Apply in thinner layers and select low-exothermic materials.

Inconsistent Coverage

- Cause:Manual application can lead to uneven layers.

- Solution: Implement automated dispensing systems for uniform coverage.

Recent Innovations Shaping the Potting Compound Market

The potting compound market is evolving with innovations that enhance performance and usability. Notable advancements include:

Smart Potting Compounds

- These compounds possess self-healing properties, allowing them to repair minor damages over time.

Nanocomposite Materials

- Incorporating nanomaterials improves thermal, mechanical, and insulating properties, catering to high-performance electronics.

Eco-Friendly Formulations

- The demand for sustainability has led to the development of biodegradable and low-VOC potting compounds.

Environmental Considerations: Developing Sustainable Potting Compounds

Sustainability is increasingly important in the development of potting compounds. Key considerations include:

Biodegradability

- Formulations that break down naturally over time to reduce environmental impact.

Low-VOC Content

- Compounds emit fewer volatile organic compounds during application, and curing enhances quality.

Sustainable Sourcing

- They are utilizing materials derived from renewable resources to minimize their ecological footprint.

Ensuring Reliability with Potting Compounds in Challenging Conditions

Circuit boards often operate in challenging environments. Potting compounds enhance reliability by providing the following:

Protection Against Temperature Extremes

- Ensuring functionality in a wide range of temperatures.

Resistance to Environmental Contaminants

- Shielding components from dust, dirt, and moisture.

Long-Term Durability

- They are extending the lifespan of electronics by preventing degradation over time.

The Future of Circuit Board Potting Technology and Materials

As technology advances, the future of potting compounds holds exciting possibilities. Expected trends include:

Integration of Smart Features

- Future compounds may incorporate sensors for real-time monitoring of environmental conditions.

Advancements in Curing Technology

- Innovations in curing processes, such as rapid curing with UV light, will streamline production.

Customizable Formulations

- Tailored potting compounds that meet specific application needs, enhancing performance and efficiency.

Conclusion

Circuit board potting compounds protect electronics in an increasingly complex and demanding environment. By enhancing moisture resistance, thermal stability, and mechanical protection, these compounds ensure the reliability and longevity of circuit boards across various applications. As innovations continue to emerge, the future of potting compounds looks promising, with sustainable and high-performance materials paving the way for enhanced electronics protection. Embracing these advancements will be crucial for manufacturers aiming to meet modern technology’s demands while ensuring their products’ reliability.

For more about understanding circuit board potting compounds: essential protection for electronics, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?