Conformal Coatings for Electronics Applications

- Electronic Potting Material Manufacturer

- August 14, 2024

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating material, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating spray, conformal coating types, conformal coating waterproof, conformal coatings for electronics, conformal coatings for electronics applications, electrical potting compound, epoxy potting compound, polyurethane potting compound, potting compound vs epoxy, silicone potting compound for electronics, UV curing potting compound, waterproof potting compound

Conformal Coatings for Electronics Applications

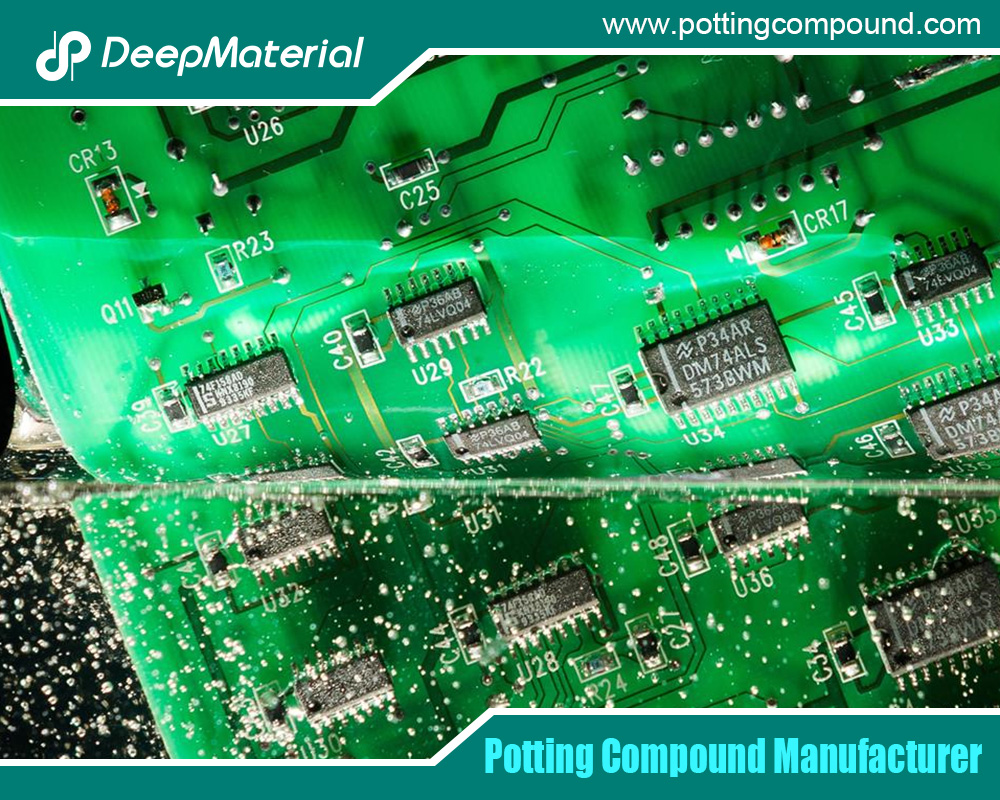

Conformal coatings are thin protective layers applied to electronic components and printed circuit boards (PCBs) to safeguard them against environmental factors such as moisture, dust, chemicals, and temperature extremes. These coatings conform to the contours of the electronics, providing a uniform layer of protection without compromising functionality. As electronic devices become more sophisticated and are used in increasingly demanding environments, the importance of conformal coatings has grown significantly.

Types of Conformal Coatings

Several types of conformal coatings are commonly used in the electronics industry, each with its unique properties and applications:

Acrylic Coatings

Acrylic conformal coatings are known for their ease of application and reworkability. They provide reasonable protection against moisture and humidity and are widely used in consumer electronics, automotive, and industrial applications. Acrylic coatings cure quickly and offer excellent electrical insulation properties. However, they may not provide the same chemical resistance level as other coatings.

Polyurethane Coatings

Polyurethane conformal coatings offer superior chemical resistance compared to acrylic coatings. They provide excellent protection against solvents, fuels, and other harsh chemicals, making them suitable for aerospace, automotive, and military applications. Polyurethane coatings also offer good moisture resistance and flexibility, but they can be more challenging to apply and rework.

Silicone Coatings

Silicone conformal coatings are known for their flexibility and high-temperature resistance. They can withstand various temperatures, making them ideal for automotive, aerospace, and outdoor applications. Silicone coatings provide excellent protection against moisture, dust, and environmental contaminants. However, they may not offer the same abrasion resistance level as other coatings.

Epoxy Coatings

Epoxy conformal coatings provide excellent mechanical strength and chemical resistance. They offer superior protection against moisture, dust, and chemicals, making them suitable for harsh environments such as oil and gas, industrial and marine applications. Epoxy coatings can be more rigid than others, which may lead to cracking under thermal stress. They are also more challenging to rework.

Parylene Coatings

Parylene conformal coatings are unique because they are applied through a vapor deposition process, resulting in an ultra-thin, uniform layer of protection. Parylene coatings offer excellent moisture, chemical, and dielectric protection and are used in medical, aerospace, and military applications. Due to their high-performance characteristics and complex application process, Parylene coatings are more expensive than other coatings.

Application Methods for Conformal Coatings

The application method for conformal coatings can significantly impact their performance and effectiveness. Various techniques are used to apply conformal coatings, including:

Brushing

Brushing is a manual method where the coating is applied using a brush. This simple and cost-effective method makes it suitable for small-scale production or rework. However, achieving a uniform coating thickness and consistency with brushing can be challenging, and it may not be ideal for high-volume production.

Spraying

Spraying is a standard application method for conformal coatings, particularly for large-scale production. The coating is sprayed onto the electronic components using a spray gun or automated system. Spraying allows for more uniform coverage and is suitable for complex geometries. However, it can result in overspray and waste, requiring proper ventilation and safety measures.

Dipping

Dipping involves immersing the electronic components in a bath of conformal coating material. This method ensures complete coverage and uniform thickness, making it ideal for high-volume production. However, controlling the coating thickness can be challenging and unsuitable for components with intricate designs or sensitive parts.

Selective Coating

Selective coating is an automated process where the conformal coating is applied only to specific areas of the electronic components. This method minimises waste, making it suitable for complex assemblies and high-volume production. Selective coating systems use robotic arms and specialised nozzles to apply the coating accurately.

Vapour Deposition

Vapour deposition is a specialised application method used for Parylene coatings. The process involves placing the electronic components in a vacuum chamber and exposing them to vaporised Parylene monomer, which polymerizes and forms a thin, uniform layer. Vapour deposition provides excellent coverage and protection but requires specialised equipment and expertise.

Advantages of Conformal Coatings

Conformal coatings offer numerous advantages for electronic components and assemblies, including:

Environmental Protection

Conformal coatings provide a barrier against moisture, dust, chemicals, and other environmental contaminants that can damage electronic components. This protection helps extend the lifespan and reliability of electronic devices, particularly in harsh environments.

Electrical Insulation

Conformal coatings offer excellent electrical insulation properties, preventing short circuits and electrical failures caused by conductive contaminants. This insulation is critical for ensuring electronic devices’ safe and reliable operation.

Thermal Management

Certain conformal coatings like silicone provide high-temperature resistance and thermal management properties. These coatings help dissipate heat and protect components from thermal stress, improving electronic devices’ overall performance and longevity.

Mechanical Protection

Conformal coatings offer mechanical protection against vibration, shock, and abrasion. This protection is essential for electronic components used in automotive, aerospace, and industrial applications, where mechanical stress occurs daily.

Cost-Effectiveness

Conformal coatings can be a cost-effective solution for protecting electronic components, reducing the need for more expensive and complex protective enclosures. They also help minimise maintenance and repair costs by enhancing the durability and reliability of electronic devices.

Challenges and Considerations

While conformal coatings offer numerous benefits, there are also challenges and considerations to keep in mind:

Application Complexity

The application process for conformal coatings can be complex, requiring specialized equipment and expertise. Ensuring uniform coverage and proper adhesion can be challenging, particularly for components with intricate designs or sensitive parts.

Rework and Repair

Reworking or repairing conformal coatings can be difficult, particularly for non-elastically removable ones like epoxy or perylene. Special care must be taken during rework or repair to avoid damaging the underlying components.

Material Selection

Selecting the appropriate conformal coating material is critical for achieving the desired level of protection and performance. Each type of coating has its unique properties and limitations, and the selection process should consider factors such as environmental conditions, mechanical stress, and chemical exposure.

Inspection and Testing

Ensuring the quality and effectiveness of conformal coatings requires thorough inspection and testing. This process can involve visual inspection, thickness measurement, adhesion testing, and electrical testing to verify the coating’s performance and integrity.

Innovations and Future Trends

The field of conformal coatings is continuously evolving, with ongoing research and development leading to new materials and application methods. Some of the key innovations and future trends in conformal coatings include:

Advanced Materials

Researchers are developing new conformal coating materials with enhanced properties, such as improved flexibility, higher temperature resistance, and more excellent chemical resistance. These advanced materials aim to provide better protection and performance for electronic components in increasingly demanding applications.

Nano-Coatings

Nano-coatings are ultra-thin conformal coatings that offer excellent protection and performance with minimal impact on the size and weight of electronic components. These coatings are being explored for various applications, including medical devices, consumer electronics, and aerospace.

Environmentally Friendly Coatings

There is a growing focus on developing environmentally friendly conformal coatings that reduce the use of hazardous chemicals and minimise environmental impact. Water-based coatings and bio-based materials are being explored as alternatives to traditional solvent-based coatings.

Smart Coatings

Innovative conformal coatings are being developed to sense and respond to environmental changes, such as temperature, humidity, or mechanical stress. These coatings can provide real-time monitoring and feedback, enhancing the reliability and performance of electronic devices.

Automation and Robotics

Advancements in automation and robotics are improving the precision and efficiency of conformal coating application processes. Automated systems can apply coatings more accurately and consistently, reducing waste and improving production throughput.

Applications of Conformal Coatings

Conformal coatings are used in a wide range of applications across various industries, including:

Consumer Electronics

Conformal coatings protect sensitive components in consumer electronics from moisture, dust, and other contaminants. This protection is essential for smartphones, tablets, and wearable devices, often exposed to everyday environmental challenges.

Automotive Electronics

Automotive electronics are subjected to harsh conditions, including temperature extremes, vibration, and exposure to chemicals and moisture. Conformal coatings provide the necessary protection to ensure the reliability and longevity of components such as engine control units (ECUs), sensors, and infotainment systems.

Aerospace and Defense

Aerospace and defence applications require high-performance conformal coatings to protect electronic components from extreme temperatures, humidity, and mechanical stress. These coatings are used in avionics, communication systems, and navigation equipment, where reliability is critical.

Medical Devices

Conformal coatings protect electronic components in devices such as pacemakers, insulin pumps, and medical diagnostic equipment. These coatings help ensure the safety and reliability of medical devices used in critical applications.

Industrial Electronics

Industrial electronics, such as control systems, sensors, and instrumentation, are often exposed to harsh environments with chemicals, dust, and temperature fluctuations. Conformal coatings provide the necessary protection to maintain the performance and reliability of these components.

Marine and Offshore

Marine and offshore applications involve exposure to saltwater, humidity, and harsh weather conditions. Conformal coatings protect electronic components in navigation systems, communication equipment, and control systems used in ships, offshore platforms, and underwater installations.

Conclusion

Conformal coatings protect electronic components and assemblies from environmental factors, ensuring their reliability and longevity. With a variety of coating materials and application methods available, it is essential to select the appropriate coating based on the specific requirements of each application. As technology advances, new materials and innovations in conformal coatings continue to emerge, offering enhanced protection and performance for electronic devices across various industries. By understanding the benefits, challenges, and future trends in conformal coatings, manufacturers can make informed decisions to safeguard their electronic products and ensure their success in demanding environments.

For more about choosing the top conformal coatings for electronics applications, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB