Conformal Coatings for Electronics Applications

- Electronic Potting Material Manufacturer

- September 14, 2024

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating material, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating spray, conformal coating suppliers, conformal coating types, conformal coating waterproof, Conformal Coatings for Electronic, conformal coatings for electronics applications, Industrial Conformal Coating, pcb conformal coating, Silicone Conformal Coating, Urethane Conformal Coating, UV Cure Conformal Coating, Waterproof Conformal Coating

Conformal Coatings for Electronics Applications

In the world of electronics, ensuring durability and reliability is paramount. One critical method for achieving this is through the application of conformal coatings. These protective layers are essential in safeguarding electronic components from environmental factors such as moisture, dust, chemicals, and temperature extremes. This article explores conformal coatings, covering their types, applications, benefits, and future trends.

1. What Are Conformal Coatings?

Conformal coatings are protective layers applied to electronic circuits and components to shield them from environmental conditions that could cause damage or failure. Unlike traditional coatings, conformal coatings are designed to conform to the contours of the substrate, providing a uniform layer of protection even in complex geometries.

1.1. Purpose and Importance

Conformal coatings’ primary purpose is to enhance the reliability and lifespan of electronic devices. They prevent moisture and contaminants from causing short circuits or corrosion, which can be detrimental to electronic assemblies’ performance. In high-reliability applications, such as aerospace, medical devices, and military electronics, conformal coatings are crucial for maintaining functionality under harsh conditions.

1.2. Types of Conformal Coatings

There are several types of conformal coatings, each with distinct properties and applications:

- Acrylic Coatings:These are popular for their ease of application and removal. Acrylic coatings provide good moisture resistance and are typically used in consumer electronics and general-purpose applications.

- Silicone Coatings:Known for their high-temperature resistance and flexibility, silicone coatings are ideal for applications exposed to extreme temperatures and vibrations. They are commonly used in the automotive and aerospace industries.

- Polyurethane Coatings:These coatings offer excellent chemical resistance and are suitable for environments where chemical exposure is a concern. They are used in industrial electronics and outdoor applications.

- Epoxy Coatings:Epoxy coatings provide robust protection against moisture and chemicals but are more rigid and difficult to remove than other types. They are often used in high-reliability and harsh environment applications.

- Parylene Coatings:Parylene coatings are applied via vapor deposition, creating a thin, uniform layer with excellent barrier properties. They are used in medical devices, electronics, and aerospace applications.

2. Application Methods

Various methods can be used to apply conformal coatings, each suited to different types of coatings and production requirements.

2.1. Spray Application

Spray application is a versatile method for acrylic, polyurethane, and silicone coatings. It involves spraying the coating onto the surface using a spray gun or aerosol can. This method is suitable for both manual and automated processes, making it ideal for prototyping and low—to medium-volume production.

2.2. Dip Coating

Dip coating involves immersing the entire assembly into a coating bath, allowing the coating to cover all surfaces. This method is commonly used for acrylic and polyurethane coatings and is suitable for high-volume production. Dip coating ensures a uniform layer but may not be ideal for assemblies with delicate components.

2.3. Brush Application

Brush application is a manual method for coating with a brush or applicator. This method is helpful for touch-ups or small-scale production but is labor-intensive and may result in uneven coating thickness.

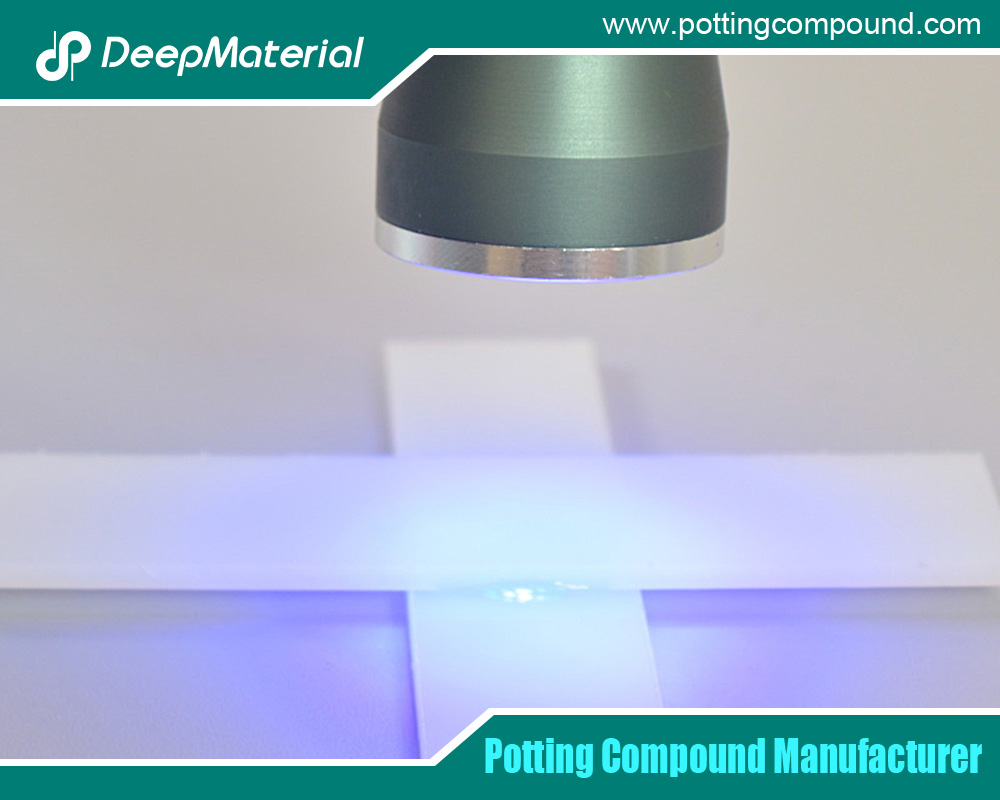

2.4. Selective Coating

Selective coating involves applying the coating only to specific areas of the assembly, typically using automated equipment. This method is ideal for protecting sensitive components while leaving other regions uncoated. It is commonly used with acrylic and silicone coatings in medium to high-volume production.

2.5. Parylene Deposition

Parylene coatings are applied using a vapor deposition process in a vacuum chamber. The coating material is vaporized and then deposited onto the substrate, creating a thin, uniform layer. This method suits applications requiring high precision and consistent coverage, such as medical devices and high-tech electronics.

3. Benefits of Conformal Coatings

Conformal coatings offer several benefits that enhance the performance and longevity of electronic devices.

3.1. Protection Against Environmental Factors

Conformal coatings provide a barrier against moisture, dust, chemicals, and temperature extremes. This protection prevents corrosion, short circuits, and degradation of electronic components, ensuring reliable performance in harsh environments.

3.2. Increased Reliability

Conformal coatings contribute to the overall reliability of electronic assemblies by protecting them from environmental stressors. This is particularly important in critical applications such as aerospace, automotive, and medical devices, where failure can have severe consequences.

3.3. Enhanced Durability

Coated electronic assemblies are more resistant to mechanical stress, vibration, and thermal cycling. This increased durability extends the device’s lifespan and reduces the need for frequent repairs or replacements.

3.4. Improved Performance

Conformal coatings can help maintain electronic components’ performance by preventing contaminants from interfering with their operation. This is especially important for high-frequency and high-precision applications, where even minor interference can impact performance.

3.5. Cost-Effectiveness

While the initial cost of applying conformal coatings may be higher, the long-term benefits outweigh the expense. The increased reliability and durability reduce the need for maintenance and replacements, ultimately resulting in cost savings over the device’s lifespan.

4. Challenges and Considerations

Despite their advantages, conformal coatings present several challenges and considerations that must be addressed.

4.1. Selection of Coating Type

Choosing the appropriate coating type for a specific application requires careful consideration of environmental conditions, component materials, and performance requirements. Each coating has its properties and limitations, making it essential to match the coating to the application’s needs.

4.2. Application Process

The application process for conformal coatings can be complex and may require specialized equipment and expertise. Ensuring uniform coverage, avoiding defects, and controlling coating thickness are critical factors in achieving optimal performance.

4.3. Compatibility with Components

Some conformal coatings may react with certain materials or components, potentially causing damage or affecting performance. To avoid issues, it is essential to test the coating’s compatibility with all components before application.

4.4. Removal and Repair

Removing conformal coatings can be challenging in cases where repairs or modifications are needed. Different coatings require different removal methods; some may be more difficult to remove than others. The coating selection process should consider repairability and ease of coating removal.

5. Future Trends in Conformal Coatings

The field of conformal coatings is continuously evolving, with ongoing research and development leading to new advancements and trends.

5.1. Advanced Materials

Researchers are exploring new materials and formulations for conformal coatings to enhance their properties and performance. Advances in nanotechnology and polymers are leading to the development of coatings with improved barrier properties, flexibility, and environmental resistance.

5.2. Smart Coatings

Innovative coatings are an emerging trend involving incorporating sensors or functional elements into the coating. These coatings can provide real-time monitoring of environmental conditions or changes in the coating’s integrity, offering additional layers of protection and diagnostic capabilities.

5.3. Eco-Friendly Coatings

There is a growing emphasis on developing eco-friendly conformal coatings that minimize environmental impact. Water-based and low-VOC (volatile organic compound) coatings are becoming more common, aligning with sustainability goals and regulatory requirements.

5.4. Integration with Automation

Integrating conformal coating processes with automation and Industry 4.0 technologies enhances production efficiency and consistency. Automated coating systems equipped with advanced control and monitoring capabilities are improving the accuracy and quality of coating applications.

Conclusion

Conformal coatings protect electronic components and ensure their reliability and longevity. With various coating types and application methods available, manufacturers can choose the best solution. While there are challenges to consider, the benefits of conformal coatings make them a valuable investment in high-performance electronics. As technology advances, the field of conformal coatings will continue to evolve, offering new solutions and innovations to meet the demands of an ever-changing electronic landscape.

For more about choosing the best Conformal Coatings for Electronics Applications, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB