Electronics Encapsulation Epoxy Adhesive: An In-Depth Exploration

- Electronic Potting Material Manufacturer

- September 11, 2024

- Automotive potting material manufacturers, Benefits of Potting Electronics, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, circuit board potting compounds, Connector Potting Compound, custom automated electronics potting, customize china electronic potting silicone factories, customize china electronic potting silicone manufacturer, customize china electronic potting silicone supplier, deepmaterial PCB Potting, deepmaterial potting compound, electrical potting compound, Electronic Encapsulant Potting Compound, Electronic Epoxy Encapsulant Potting Compound, Electronic Epoxy Potting Compound, electronics encapsulation adhesive, electronics encapsulation epoxy adhesive, electronics encapsulation epoxy adhesive glue, electronics epoxy adhesive, encapsulation adhesive, encapsulation epoxy adhesive, pcb encapsulation epoxy adhesive glue

Electronics Encapsulation Epoxy Adhesive: An In-Depth Exploration

Reliability and durability are crucial in the ever-evolving world of electronics. One pivotal technology ensuring these characteristics in electronic devices is the use of encapsulation epoxy adhesives. These materials protect electronic components from environmental factors, mechanical stress, and chemical attacks. This article delves into the intricacies of electronics encapsulation epoxy adhesive, exploring its composition, applications, benefits, and the latest advancements in this critical technology.

Composition and Types of Electronics Encapsulation Epoxy Adhesive

Electronics encapsulation epoxy adhesives are specialized materials that safeguard electronic components and assemblies. These adhesives are formulated to offer both excellent bonding properties and exceptional protection against various external stresses. The primary components of these epoxies include:

Resins

The base of any epoxy adhesive is its resin, which provides the fundamental adhesive properties. The most common resins in electronics encapsulation are bisphenol A (BPA) and bisphenol F (BPF) epoxies. These resins offer good chemical resistance and thermal stability, making them suitable for electronic applications.

Hardeners

Hardeners, or curing agents, are added to epoxy resins to initiate the curing process. The choice of hardener affects the epoxy’s final properties, including its thermal resistance, mechanical strength, and chemical resistance. Standard hardeners include amines, anhydrides, and phenolic compounds.

Fillers and Additives

Fillers and additives are incorporated to enhance the epoxy’s performance. These may include silica, alumina, or graphite, which improve thermal conductivity, mechanical strength, and electrical insulation properties. Additives like flame retardants and UV stabilizers are also used to enhance specific characteristics.

Solvents

Solvents adjust the epoxy’s viscosity in some formulations for a more straightforward application. However, many modern encapsulation epoxies are solvent-free to reduce environmental impact and health risks.

Applications of Electronics Encapsulation Epoxy Adhesive

Electronics encapsulation epoxy adhesives are used in a wide range of applications to provide protection and improve the reliability of electronic devices. Some of the critical applications include:

Component Encapsulation

Epoxy adhesives are widely used to encapsulate electronic components such as integrated circuits (ICs), sensors, and microprocessors. This encapsulation protects the components from moisture, dust, and mechanical damage, ensuring long-term reliability.

PCB Coating

Printed Circuit Boards (PCBs) are essential in electronic devices, and their protection is crucial for device performance. Epoxy adhesives are coatings that shield PCBs from environmental factors and mechanical stress.

Thermal Management

In electronic assemblies, managing heat is critical to prevent overheating and ensure optimal performance—epoxy adhesives with high thermal conductivity bond heat sinks and other thermal management components to electronic devices.

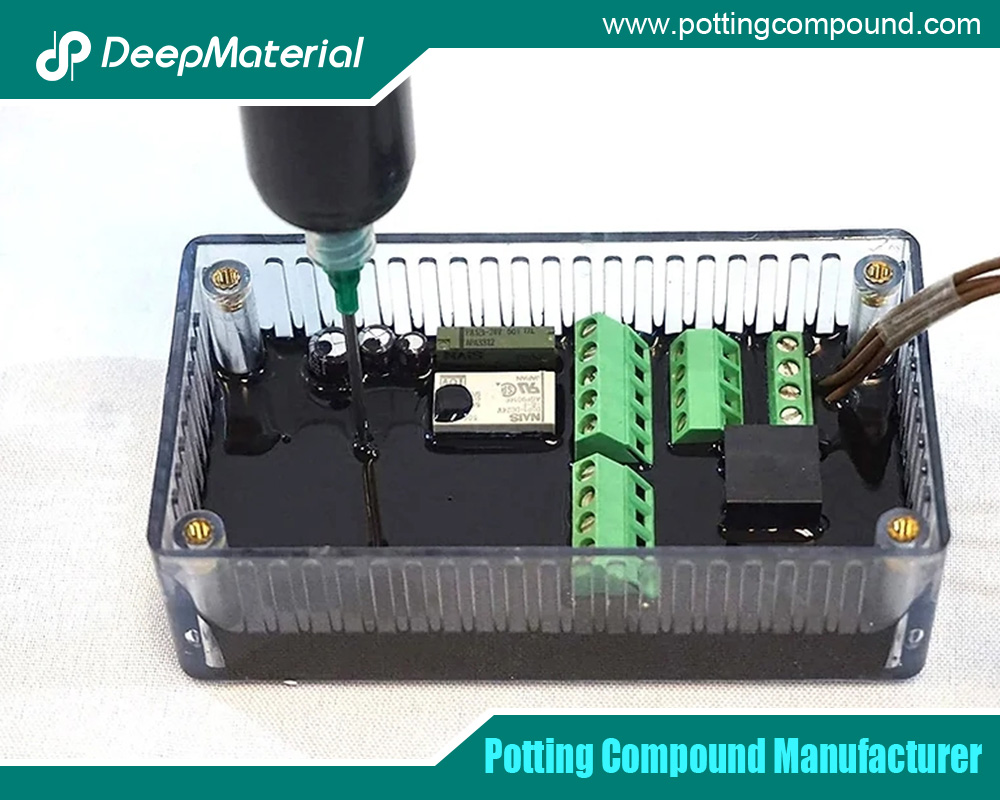

Potting and Encapsulation

Potting involves filling a cavity or enclosure with epoxy adhesive to protect sensitive electronic components from vibration, shock, and environmental factors. This method is commonly used in automotive electronics, aerospace, and military applications.

Wire Bonding and Die Attach

Epoxy adhesives bond wires to semiconductor die and attach dies to substrates. To ensure reliable performance, these adhesives must have excellent electrical insulation properties and thermal stability.

Benefits of Electronics Encapsulation Epoxy Adhesive

The use of encapsulation epoxy adhesives offers numerous advantages in the electronics industry. Some of the key benefits include:

Enhanced Protection

Epoxy adhesives provide robust protection against moisture, chemicals, and mechanical stress. This protection is crucial for maintaining the reliability and longevity of electronic components and assemblies.

Improved Thermal Management

Epoxy adhesives with high thermal conductivity help dissipate heat efficiently, preventing overheating and improving electronic device performance.

Mechanical Strength

The mechanical strength of epoxy adhesives ensures that electronic components remain securely attached and protected from physical damage, vibration, and shock.

Electrical Insulation

Epoxy adhesives offer excellent electrical insulation properties, preventing short circuits and interference from electronic components.

Chemical Resistance

Epoxy adhesives resist various chemicals, including acids, bases, and solvents. This resistance is essential for electronics exposed to harsh environments.

Customizable Properties

Epoxy adhesives can be formulated to meet specific requirements, including adjusting curing times, viscosity, and mechanical properties. This customization allows for optimal performance in different applications.

Challenges and Considerations

While encapsulation epoxy adhesives offer numerous benefits, some challenges and considerations must be addressed:

Curing Process

Temperature, humidity, and the specific formulation used can influence the curing process of epoxy adhesives. Ensuring proper curing conditions is crucial for achieving the desired properties.

Processing and Application

Applying epoxy adhesives requires precise control to ensure even coating and avoid defects. Inadequate application can lead to complete protection and improved performance.

Environmental Impact

Some epoxy adhesives contain solvents and other chemicals that can have environmental and health impacts. The industry increasingly focuses on developing environmentally friendly formulations to address these concerns.

Cost

High-performance epoxy adhesives can be costly, which may impact the overall cost of electronic assemblies. However, the benefits of enhanced protection and reliability often justify the investment.

Recent Advancements in Electronics Encapsulation Epoxy Adhesive

The field of electronics encapsulation epoxy adhesives is continuously evolving, with ongoing research and development leading to significant advancements. Some of the recent trends and innovations include:

Low-Viscosity and High-Flow Epoxies

New formulations of low-viscosity and high-flow epoxies make it easier to apply adhesive coatings evenly and penetrate complex geometries. This advancement improves the reliability and performance of encapsulated components.

Enhanced Thermal Conductivity

Recent developments focus on improving the thermal conductivity of epoxy adhesives. These advancements help better manage heat in high-performance electronic devices like computing and telecommunications.

Environmentally Friendly Formulations

The industry is increasingly adopting environmentally friendly formulations that reduce the use of solvents and other harmful chemicals. These green epoxies contribute to sustainability and reduce health risks.

Advanced Fillers and Additives

The incorporation of advanced fillers and additives enhances the properties of epoxy adhesives. For example, nanomaterials and new flame retardants improve thermal conductivity, mechanical strength, and fire resistance.

Smart Epoxies

Research into intelligent epoxies involves developing adhesives with responsive properties, such as self-healing or adaptive behavior. These smart materials offer the potential for improved reliability and performance in demanding applications.

Conclusion

Electronic encapsulation epoxy adhesives are a cornerstone technology in the electronics industry, providing essential protection and enhancing the performance and reliability of electronic devices. Their composition, applications, and benefits highlight their critical role in modern electronics. As technology advances, epoxy adhesive innovations drive performance, sustainability, and functionality improvements. Understanding these advancements and considerations is crucial for selecting and utilizing the suitable encapsulation epoxy adhesive for specific applications, ensuring the longevity and reliability of electronic components and assemblies.

For more about choosing the best electronics encapsulation epoxy adhesive: an in-depth exploration, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Conformal Coating vs. Potting: What’s the Difference for Your PCB?

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

Tags

Related Posts

Common Mistakes to Avoid When Applying Conformal Coating

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB