Epoxy Resin for Potting Electronics: A Comprehensive Guide

- Electronic Potting Material Manufacturer

- November 21, 2024

- circuit board potting, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, conformal coating material, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating spray, conformal coating waterproof, electrical potting compound, electronic epoxy encapsulant potting compounds, epoxy conformal coating, epoxy potting compound, epoxy resin for potting electronic, pcb conformal coating, polyurethane potting compound, potting compound for electronics, potting compound for pcb, potting compound vs epoxy, Silicone Conformal Coating, silicone potting compound for electronics, thermal potting compound, Urethane Conformal Coating, UV Cure Conformal Coating, UV curing potting compound, waterproof potting compound, what is pcb potting

Epoxy Resin for Potting Electronics: A Comprehensive Guide

In the rapidly evolving world of electronics, ensuring the longevity and reliability of components is more critical than ever. As devices become increasingly compact and complex, manufacturers must seek practical solutions to protect sensitive electronic components from environmental factors, mechanical stress, and electrical failures. Potting, specifically epoxy resin, is one of the most effective methods. This blog post will provide a comprehensive overview of epoxy resin for potting electronics, including its properties, benefits, applications, the potting process, challenges, and future trends.

Understanding Epoxy Resin

Epoxy resin is a thermosetting polymer consisting of an epoxy group and a hardener. When mixed, these components undergo a chemical reaction that transforms the liquid resin into a solid material. Epoxy resins are known for their excellent adhesive properties, chemical resistance, and durability, making them ideal for potting applications in electronics.

Critical Characteristics of Epoxy Resin

- High Adhesion: Epoxy resins bond well with various substrates, including metals, plastics, and ceramics.

- Chemical Resistance: They resist degradation from various chemicals, including oils, solvents, and moisture.

- Thermal Stability: Epoxy resins can withstand high temperatures, making them suitable for applications with varying thermal conditions.

- Electrical Insulation: Their high dielectric strength makes them effective electrical insulators, preventing short circuits and enhancing signal integrity.

- Low Shrinkage: Epoxy resins exhibit minimal shrinkage during curing, ensuring a precise fit around electronic components.

Why Use Epoxy Resin for Potting Electronics?

Using epoxy resin for potting electronics offers several significant advantages:

Protection from Environmental Factors

Epoxy resin provides a robust barrier against environmental hazards, including:

- Moisture: Prevents corrosion and water damage, crucial for outdoor and industrial applications.

- Dust and Contaminants:Seals electronic components, keeping them clean and functional.

- UV Radiation:Protects against degradation caused by ultraviolet exposure.

Enhanced Mechanical Strength

The encapsulation of electronic components with epoxy resin improves their mechanical integrity, offering:

- Vibration Resistance: Reduces the risk of component damage in high-vibration environments, such as automotive and aerospace applications.

- Impact Protection:Safeguards sensitive electronics from physical shocks and impacts.

Improved Electrical Performance

Epoxy resin enhances the electrical performance of electronic components by providing:

- Excellent Dielectric Properties: Reduces the risk of electrical failures and ensures reliable operation.

- Signal Integrity:Maintains signal quality in sensitive electronic systems, preventing interference and degradation.

Cost-Effectiveness

While the initial investment in epoxy resin may be higher than some alternatives, the long-term benefits can outweigh the costs, including:

- Reduced Failures:Minimizes the need for repairs and replacements, leading to lower maintenance costs.

- Extended Lifespan:Prolongs the operational life of electronic devices, providing a better return on investment.

Applications of Epoxy Resin in Potting Electronics

Epoxy resin is widely used in various electronic applications due to its protective properties. Some typical applications include:

Consumer Electronics

- Smartphones and Tablets: Protects internal components from moisture, dust, and mechanical stress, enhancing durability.

- Wearable Devices: Encapsulates sensitive electronics in smartwatches and fitness trackers to withstand daily wear and tear.

Automotive Electronics

- Control Units:Safeguards critical electronic vehicle control units from vibrations and environmental exposure.

- Sensors: Protects automotive sensors from moisture and contaminants, ensuring reliable performance.

Industrial Equipment

- Control Panels: Encapsulates electronic components in control panels to ensure reliability in harsh industrial environments.

- Robotics:Protects sensitive electronics in robots from dust and moisture, extending their operational life.

Medical Devices

- Diagnostic Equipment:Ensures the reliable operation of electronic components in diagnostic machines by protecting them against environmental hazards.

- Implantable Devices: Encapsulates electronics in implantable devices, providing biocompatibility and moisture resistance.

Aerospace

- Flight Control Systems: Protects critical electronics in flight control systems from extreme conditions, ensuring safe operation.

- Navigation Equipment: Encapsulates sensitive electronics in navigation systems to prevent failure in harsh environments.

The Epoxy Potting Process: Step-by-Step

The epoxy resin potting process involves several critical steps to ensure optimal performance and protection. Here’s a detailed breakdown:

Step 1: Preparation

Proper preparation is essential for a successful potting process. Key actions include:

- Cleaning the Components:Remove dirt, dust, and grease from the electronic components to ensure proper adhesion of the epoxy resin.

- Drying:Ensure the components are dehydrated to prevent moisture interference during potting.

Step 2: Selecting the Epoxy Resin

Choosing the suitable epoxy resin is crucial for achieving the desired performance characteristics. Considerations include:

- Material Properties: Select epoxy resins with suitable viscosity, curing time, and thermal stability for the application.

- Compatibility: To avoid adverse reactions, ensure that the epoxy resin is compatible with the materials used in the electronic components.

Step 3: Mixing the Epoxy Resin

Mixing the epoxy resin with the hardener is a critical step in the potting process:

- Proportions:Follow the manufacturer’s guidelines for the correct mixing ratio to ensure optimal curing and performance.

- Mixing Technique:Use a clean container and mix thoroughly to ensure a uniform consistency.

Step 4: Application of the Epoxy Resin

The application method for the epoxy resin can vary depending on the specific requirements of the components:

- Manual Application:This method is suitable for small batches or specialized components. It may involve pouring or dispensing the epoxy resin by hand.

- Automated Dispensing: This is ideal for large-scale production, where precise dispensing of the epoxy resin is required. Automated systems can utilize various methods, such as syringe dispensing or pressure pots.

Step 5: Curing the Epoxy Resin

Curing hardens the epoxy resin to form a solid encapsulation around the components. This can be achieved through various methods:

- Room Temperature Curing:Some epoxy resins cure at ambient temperatures, making this method convenient and energy-efficient.

- Heat Curing:Applying heat can accelerate the curing process and enhance the properties of the epoxy resin, resulting in a stronger bond.

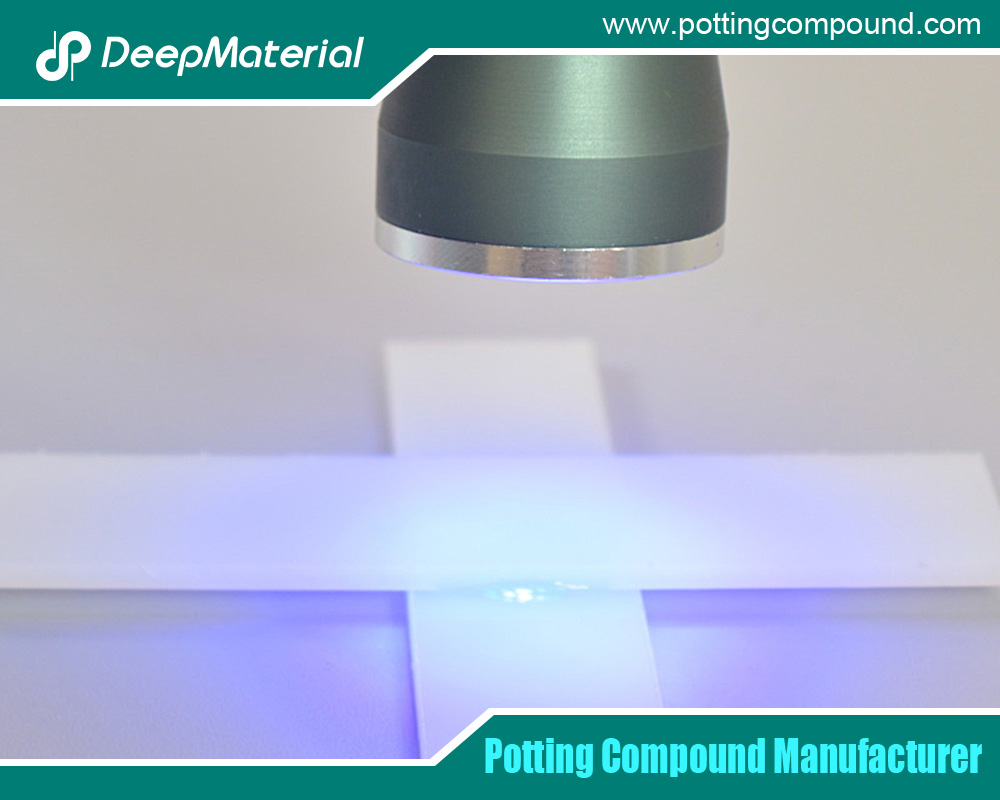

- UV Curing: Certain epoxy formulations can be cured using ultraviolet light, providing quick curing times and high-performance characteristics.

Step 6: Quality Control

After completing the potting process, conducting quality control checks is crucial to ensure the components meet the required specifications. This may include:

- Visual Inspection: Checking for any defects or irregularities in the epoxy encapsulation.

- Electrical Testing: Verifying the electrical performance of the encapsulated components to ensure they function as intended.

Benefits of Using Epoxy Resin for Potting Electronics

The use of epoxy resin for potting electronics provides numerous benefits, including:

- Enhanced Durability: Protects components from environmental hazards, ensuring long-lasting performance.

- Improved Reliability: Reduces the likelihood of component failures, leading to more excellent system reliability.

- Cost Savings: Lowers maintenance and repair costs by minimizing the need for replacements.

- Versatility:Suitable for various applications across multiple industries, including automotive, aerospace, medical devices, and consumer electronics.

Challenges in Using Epoxy Resin for Potting Electronics

While epoxy resin offers significant advantages for potting applications, there are also challenges that manufacturers must consider:

Material Selection

Choosing the appropriate epoxy resin is critical, as different materials exhibit varying properties. Factors to consider include:

- Curing Time:Longer curing times can slow production, while quick-curing materials may compromise performance.

- Thermal Stability: Selecting a resin that can withstand the operating temperatures of the application is essential.

Application Techniques

Applying epoxy resin can be challenging, particularly for complex component designs. Issues may arise from:

- Air Entrapment:Care must be taken to avoid trapping air bubbles during application, which can compromise the protective barrier.

- Inconsistent Coating: Ensuring a uniform application is essential for adequate protection.

Curing Conditions

Achieving the right curing conditions is crucial for optimal performance. Factors include:

- Temperature and Humidity: Fluctuations in these conditions can affect curing, leading to inconsistent results.

- Time Constraints: Balancing the need for quick production with the required curing times can be challenging.

Conclusion

Epoxy resin has emerged as a vital solution for potting electronics. It offers exceptional protection against environmental hazards, mechanical stress, and electrical failures. Its unique properties make it ideal for various applications across multiple industries, from consumer electronics to aerospace.

For more about choosing the top epoxy resin for potting electronics: a comprehensive guide, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB