Laptop Tablet Assembly Adhesive: The Key to Durable and Reliable Device Construction

- Electronic Potting Material Manufacturer

- December 30, 2024

- Acrylic Conformal Coating, Connector Potting Compound, Electronic Conformal Coating, electronic potting compound, epoxy conformal coating, epoxy potting compound, epoxy potting compound manufacturer, Flexible Potting Compound, Industrial Conformal Coating, Laptop Tablet Assembly Adhesive Factory, Laptop Tablet Assembly Adhesive Hotsale, Laptop Tablet Assembly Adhesive Manufacturer, Laptop Tablet Assembly Adhesive OEM, Laptop Tablet Assembly Adhesive Supplier, Laptop Tablet Assembly Adhesive Wholesale, LED Potting Compound, pcb conformal coating, PCB Potting Compound, polyurethane potting compound, Silicone Conformal Coating, Silicone Potting Compound, Urethane Conformal Coating, UV Cure Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating, waterproof potting compound

Laptop Tablet Assembly Adhesive: The Key to Durable and Reliable Device Construction

In today’s fast-paced world, laptops and tablets are essential tools for personal and professional use. As these devices become more advanced and sleek, assembling them efficiently without sacrificing quality becomes increasingly complex. One of the critical components in the manufacturing process is “Laptop Tablet Assembly Adhesive.” Adhesives are crucial for maintaining these devices’ structural integrity, durability, and aesthetic appeal. This article will explore the significance of assembly adhesives in laptops and tablets, their benefits, different types, and how they contribute to the overall performance of electronic devices.

Why Laptop Tablet Assembly Adhesive is Essential

The modern design of laptops and tablets requires that internal components, such as screens, batteries, and circuit boards, be securely bonded without using bulky mechanical fasteners like screws or clips. Adhesives are pivotal in ensuring these devices maintain their sleek design while being durable and reliable.

Benefits of Using Assembly Adhesive in Laptops and Tablets

Assembly adhesives offer several advantages that enhance the manufacturing process and the performance of finished products. Understanding these benefits helps manufacturers choose the most suitable adhesive for their needs.

Improved Durability

- Adhesives used in laptop and tablet assembly create a strong bond that resists impacts, vibrations, and other mechanical stresses. It enhances the device’s overall durability, ensuring it can withstand regular use and accidental drops.

Enhanced Aesthetics

- Unlike traditional fasteners like screws or bolts, adhesives can be applied invisibly, allowing manufacturers to produce sleeker, more streamlined designs. It is essential for devices like tablets, where minimalism and aesthetics are vital to their appeal.

Lightweight Design

- Adhesives contribute to lighter devices by eliminating the need for mechanical fasteners. It is particularly critical for tablets and laptops, where portability is a top priority.

Types of Laptop Tablet Assembly Adhesives

Different types of adhesives are used in the assembly of laptops and tablets, each offering distinct properties suited to specific applications. The choice of adhesive depends on factors such as the materials being bonded, the environmental conditions the device will face, and the desired durability.

1. Epoxy Adhesives

Epoxy adhesives are commonly used in electronics assembly due to their strong bonding capabilities and heat, chemicals, and mechanical stress resistance. They form a rigid bond that provides excellent structural support.

Advantages:

- High-strength bond

- Excellent resistance to heat and chemicals

- Long-lasting durability

Disadvantages:

- Longer curing time

- Less flexibility, which may not be ideal for components that need some movement

2. Acrylic Adhesives

Acrylic adhesives are known for their fast curing times and flexibility, making them suitable for applications where movement or vibration is a concern. They balance strength and elasticity well, making them ideal for bonding lightweight components.

Advantages:

- Quick curing time

- High flexibility and resilience

- Good resistance to environmental factors like moisture and UV light

Disadvantages:

- It may not provide as strong a bond as epoxies

- Can become brittle over time in extreme conditions

3. Silicone Adhesives

Silicone adhesives are valued for their high flexibility and resistance to temperature changes, making them ideal for devices exposed to varying environmental conditions. They commonly bond components that need to move or flex slightly.

Advantages:

- Excellent temperature resistance

- High flexibility and elasticity

- It provides a strong seal against water and dust

Disadvantages:

- Lower bonding strength compared to epoxies and acrylics

- It can take longer to cure

4. Polyurethane Adhesives

Polyurethane adhesives are versatile and offer a combination of strength and flexibility. They are used in applications where components must be bonded securely but require flexibility to absorb shocks or vibrations.

Advantages:

- Strong, flexible bond

- Resistant to moisture, chemicals, and environmental factors

- Can bond a variety of materials, including plastics and metals

Disadvantages:

- More expensive than other types of adhesives

- Requires careful handling and precise application

Factors to Consider When Selecting Laptop Tablet Assembly Adhesive

Selecting the suitable adhesive for laptop and tablet assembly is a critical step that directly impacts the device’s performance, durability, and safety. Several factors should be considered when choosing an adhesive.

- Material Compatibility

- The adhesive must be compatible with the materials used in the device, such as plastics, metals, glass, or composites. Using an incompatible adhesive can lead to weak bonds or degradation over time.

Strength and Flexibility

- Depending on the components being bonded, manufacturers must decide whether they need a rigid bond for structural support or a flexible bond to absorb shocks and vibrations.

Thermal Management

- Devices like laptops and tablets generate significant heat during operation, particularly around the battery and processor. Adhesives with good thermal conductivity help dissipate this heat, ensuring the device stays cool and performs efficiently.

Environmental Resistance

- Laptops and tablets are often exposed to various environmental factors, including moisture, dust, and temperature changes. Adhesives that resist these elements ensure the device remains functional and protected in different environments.

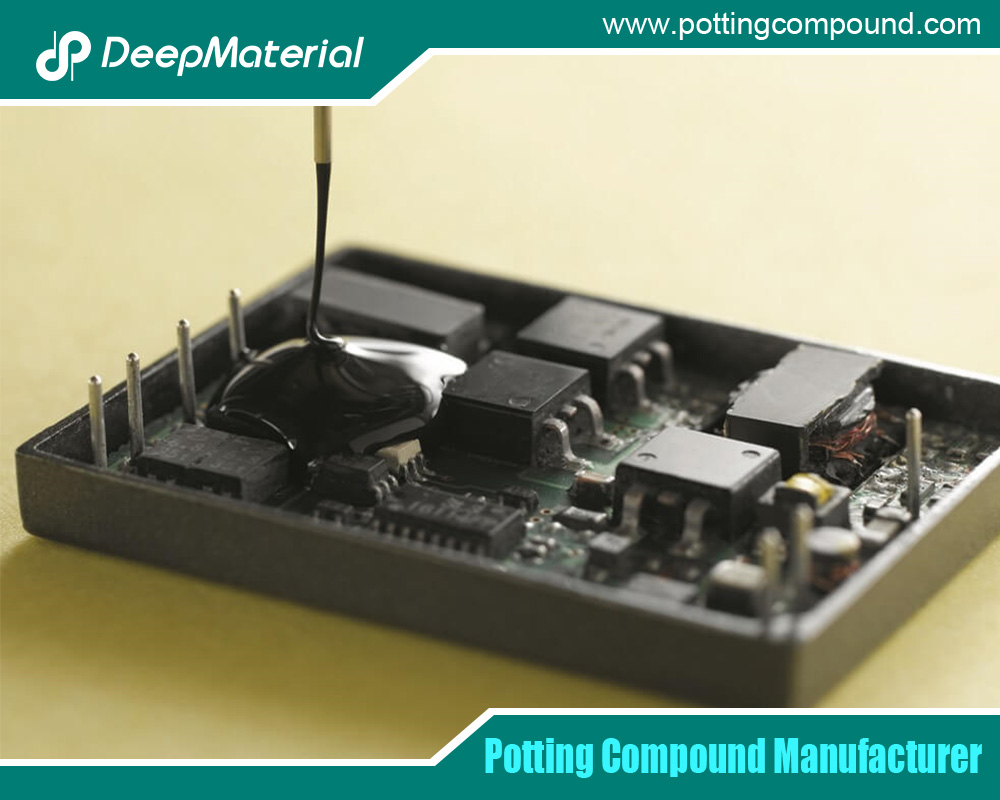

Applications of Laptop Tablet Assembly Adhesive

Adhesives are used in various parts of laptops and tablets to ensure their stability and performance. Each component has specific adhesive requirements based on its role in the device’s functionality.

Bonding the Display

- The display is one of the most delicate components in a laptop or tablet, and adhesives are used to securely attach it to the frame without adding bulk. It ensures that the display remains fixed and protected during regular use.

Securing the Battery

- The battery is a crucial component that needs to be securely fastened to prevent it from moving or becoming damaged. Adhesives provide a stable bond that keeps the battery in place, even when the device is subjected to movement or impact.

Attaching Circuit Boards

- The circuit boards in laptops and tablets are responsible for the device’s functionality, and adhesives hold them securely in place. It ensures that the electrical components remain protected and stable during operation.

Securing Ports and Connectors

- Adhesives are also used to secure the various ports and connectors on the device, ensuring they remain functional and do not become loose over time. This contributes to the device’s durability and usability.

Advantages of Using Adhesives Over Mechanical Fasteners

While mechanical fasteners like screws and bolts have been traditionally used in the assembly of electronic devices, adhesives offer several advantages that make them the preferred choice in modern laptop and tablet construction.

- Weight Reduction:Adhesives eliminate the need for bulky fasteners, contributing to a lighter and more portable device.

- Improved Aesthetics: Adhesives can be applied invisibly, allowing for a cleaner and more streamlined design.

- Faster Assembly:Adhesives can speed up the manufacturing process, as they do not require the time-consuming steps involved in mechanical fastening.

- Enhanced Durability:Adhesives provide better resistance to vibrations and shocks than mechanical fasteners, ensuring the device remains functional over time.

Challenges in Using Laptop Tablet Assembly Adhesives

While adhesives offer many benefits, challenges are associated with their use in laptop and tablet assembly.

- Precision Application

- Applying adhesives requires precision to ensure that the right amount is used in the correct locations. Too much adhesive can lead to unsightly oozing, while too little can weaken bonds.

- Curing Time Management

- Some adhesives require time to cure before they reach their full strength, slowing the production process. Manufacturers must balance the need for fast assembly with the desire for durable, long-lasting bonds.

- Cost Considerations

- High-quality adhesives may be more expensive than traditional mechanical fasteners but often offer better performance and longevity. Manufacturers must weigh the costs against the benefits when choosing adhesives.

Conclusion

In conclusion, “Laptop Tablet Assembly Adhesive” plays a crucial role in the construction of modern electronic devices, offering benefits such as improved durability, heat management, and environmental protection. Different types of adhesives, including epoxy, acrylic, silicone, and polyurethane, are used to meet the specific needs of laptops and tablets. Manufacturers must carefully consider material compatibility, thermal management, and environmental resistance when selecting the suitable adhesive for their devices. While there are challenges associated with the use of adhesives, their advantages in terms of design flexibility, weight reduction, and performance make them the preferred choice in the assembly of today’s laptops and tablets.

For more about choosing the laptop tablet assembly adhesive: the key to durable and reliable device construction, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Conformal Coating vs. Potting: What’s the Difference for Your PCB?

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

Tags

Related Posts

Common Mistakes to Avoid When Applying Conformal Coating

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB