Protecting Innovation: Exploring The Role Of Electronic Encapsulation Suppliers

- Electronic Potting Material Manufacturer

- June 18, 2024

- circuit board encapsulation, electrical encapsulation, electronic board level underfill and encapsulation material market, electronic encapsulation, Electronic encapsulation process, Electronic Encapsulation Suppliers, Electronic Potting and Encapsulation, Electronic Potting and Encapsulation Resins, electronics encapsulation, electronics encapsulation epoxy, encapsulation compounds, encapsulation electronics, encapsulation epoxy, encapsulation of electronic components, encapsulation resins industry, Encapsulation Technologies for Electronic Applications, epoxy encapsulation electronic components, led encapsulation epoxy, pcb encapsulation, pcb encapsulation epoxy, potting and encapsulation, potting and encapsulation machine, potting and encapsulation process, potting and encapsulation services, potting encapsulation, resin encapsulation service

Protecting Innovation: Exploring The Role Of Electronic Encapsulation Suppliers

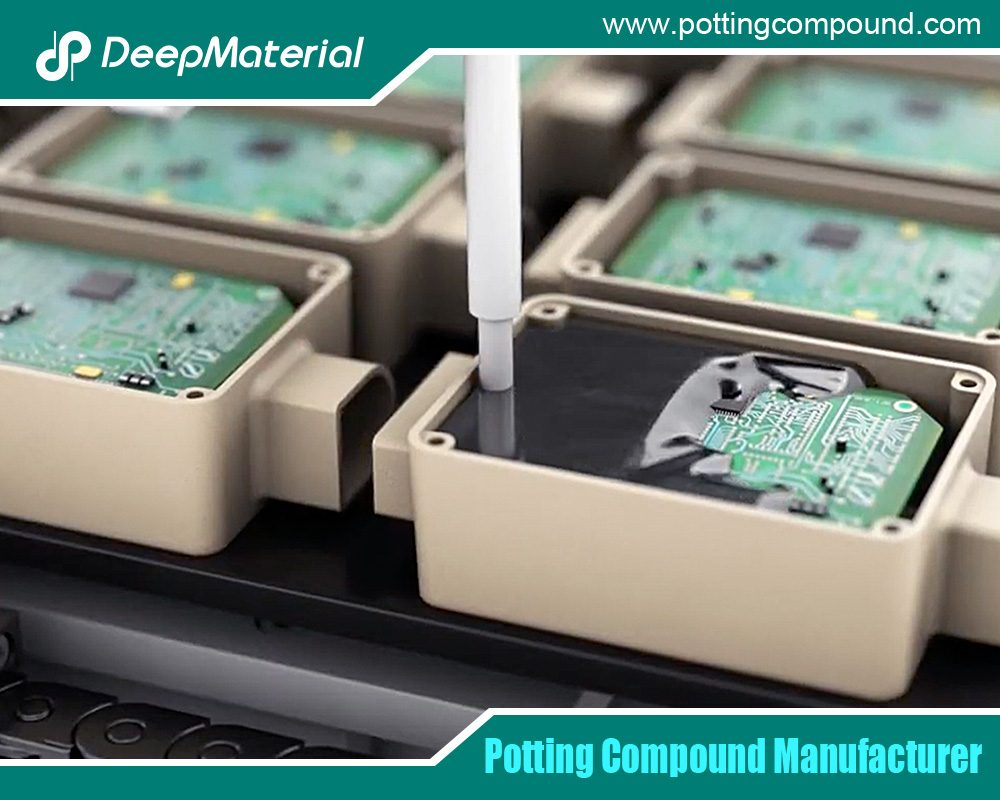

In electronics, safeguarding delicate components against environmental factors is essential for optimal performance and longevity. Electronic encapsulation, the sealing components within protective materials, is crucial in achieving this goal. Behind every successful encapsulation lies a dedicated supplier offering specialized materials and expertise to meet the diverse needs of electronic manufacturers. In this blog post, we delve into the world of electronic encapsulation suppliers, uncovering their significance, offerings, challenges, and prospects.

The Vital Role of Electronic Encapsulation Suppliers

Electronic encapsulation suppliers are pivotal in the electronics industry, providing essential materials and expertise for protecting sensitive electronic components. These suppliers offer a wide range of encapsulation materials, including resins, gels, and coatings, tailored to meet the diverse needs of electronic manufacturers across various sectors. Through their extensive knowledge of materials science and engineering, electronic encapsulation suppliers assist manufacturers in selecting the most suitable encapsulation solutions for their specific applications, ensuring optimal performance and reliability.

Moreover, electronic encapsulation suppliers are valuable partners throughout the encapsulation process, from material selection to application and quality assurance. They offer technical support and guidance to manufacturers, helping them navigate the complexities of encapsulation and overcome any challenges that may arise. By collaborating closely with their clients, electronic encapsulation suppliers ensure that the encapsulation materials meet stringent industry standards and regulatory requirements while also addressing the unique demands of each application.

In an ever-evolving technological landscape, electronic encapsulation suppliers play a vital role in driving innovation and advancing the capabilities of electronic devices. They continuously research and develop new encapsulation materials and techniques to address emerging challenges and meet the evolving needs of the electronics industry. By staying at the forefront of technological advancements, electronic encapsulation suppliers empower manufacturers to create more robust, reliable, and durable electronic products that can withstand the rigors of various environments and applications.

Types of Encapsulation Materials and Their Properties

Electronic encapsulation suppliers are instrumental in providing various encapsulation materials essential for protecting electronic components from environmental stressors. This paragraph explores the different types of encapsulation materials offered by these suppliers and their fundamental properties, highlighting their significance in ensuring the reliability and longevity of electronic devices.

Epoxy Resins:

Epoxy resins are widely used encapsulation materials known for their excellent adhesion, chemical resistance, and mechanical strength. These materials form a robust protective barrier around electronic components, shielding them from moisture, dust, and other contaminants. Epoxy resins are available in various formulations, including thermally conductive and flame-retardant options, making them suitable for diverse applications in the automotive, aerospace, and consumer electronics industries.

Silicone Gels:

Silicone gels are highly flexible encapsulation materials with exceptional thermal stability and shock absorption properties. These materials conform to complex shapes and uneven surfaces, protecting delicate electronic components against mechanical stress and thermal cycling. Silicone gels are also known for their transparency and resistance to yellowing, making them ideal for applications requiring optical clarity, such as LED lighting and optical sensors.

Polyurethane Coatings:

Polyurethane coatings are versatile encapsulation materials prized for their durability, flexibility, and resistance to abrasion and chemicals. These materials form a rigid yet flexible protective layer that withstands harsh environmental conditions, including exposure to UV radiation and extreme temperatures. Polyurethane coatings are available in different viscosities and cure times, allowing customized solutions tailored to specific application requirements in marine, industrial automation, and telecommunications industries.

Customization and Tailored Solutions

In the intricate ecosystem of electronic manufacturing, the role of an electronic encapsulation supplier is paramount. These suppliers are the cornerstone for safeguarding delicate electronic components from environmental factors and mechanical stress, ensuring the longevity and reliability of electronic devices across various industries. Offering a spectrum of customization and tailored solutions, these suppliers cater to their client’s unique needs and specifications, providing unparalleled protection and performance enhancement for electronic assemblies.

- Tailored Material Selection: To ensure optimal protection for electronic components, electronic encapsulation suppliers meticulously select materials based on their client’s requirements, considering factors such as moisture resistance, thermal conductivity, flexibility, and adhesion properties.

- Customized Formulations: Through collaboration and iterative testing, suppliers develop customized formulations to meet the precise performance criteria of their clients’ electronic applications, whether for the aerospace, automotive, medical, or industrial sectors.

- Application-Specific Designs: Suppliers design encapsulation solutions tailored to the unique geometries and configurations of their clients’ electronic assemblies, ensuring seamless integration and optimal protection.

- Prototyping and Testing Services: Electronic encapsulation suppliers offer prototyping and testing services to validate the performance and reliability of encapsulation solutions under real-world conditions, allowing for iterative refinement and optimization.

- Responsive Customer Support: With a focus on customer satisfaction, suppliers provide responsive support throughout the design, development, and implementation phases, offering technical expertise and guidance to address any challenges or concerns.

Through collaboration, innovation, and a commitment to excellence, electronic encapsulation suppliers empower electronic manufacturers to deliver products of the highest quality and reliability, driving technological advancements and enhancing the user experience across diverse applications.

Challenges Faced by Suppliers

In electronic manufacturing, electronic encapsulation suppliers play a vital role in ensuring the protection and durability of electronic components. However, they encounter various challenges that demand innovative solutions to maintain efficiency and quality in their services.

- Material Selection: Suppliers face a significant challenge in choosing the appropriate encapsulation materials to meet the diverse requirements of different electronic applications.

- Customization Demands: Meeting the increasing demand for customized encapsulation solutions tailored to specific client needs requires flexibility and adaptability in manufacturing processes.

- Quality Control: Ensuring consistent quality and reliability of encapsulation materials amidst variations in production conditions and raw materials is essential but challenging.

- Adherence to Standards and Regulations: Staying abreast of evolving industry standards and regulatory requirements adds complexity to the manufacturing process and demands continuous compliance efforts.

- Supply Chain Disruptions: Supply chain disruptions, whether due to geopolitical tensions, natural disasters, or pandemics, can disrupt production schedules and impact the availability of critical materials and components.

Future Outlook: Navigating Towards Growth

The future outlook for electronic encapsulation suppliers is promising as the demand for reliable and efficient electronic devices continues to rise. This paragraph explores the anticipated growth and opportunities for electronic encapsulation suppliers, highlighting critical areas of focus for navigating toward growth in the evolving electronics industry.

Technological Advancements:

Electronic encapsulation suppliers must leverage technological advancements to develop innovative materials and solutions. These efforts encompass integrating nanotechnology for enhanced performance, developing self-healing coatings for improved durability, and utilizing sustainable materials for eco-friendly encapsulation options.

Expansion into Emerging Markets:

As electronic devices become more ubiquitous across industries, electronic encapsulation suppliers can expand into emerging markets such as wearable technology, IoT (Internet of Things), and electric vehicles. Suppliers can capitalize on growing demand and establish a strong presence in rapidly evolving sectors by offering specialized encapsulation solutions tailored to these markets’ unique requirements.

Focus on Sustainability:

With increasing awareness of environmental issues, electronic encapsulation suppliers are expected to prioritize sustainability in their product offerings and manufacturing processes. Encapsulation suppliers increasingly focus on developing biodegradable materials, utilizing recycled resources, and adopting eco-friendly production practices to minimize environmental impact and meet evolving regulatory requirements.

Conclusion

Electronic encapsulation suppliers play a crucial role in protecting innovation and driving the advancement of electronic devices. Through customized solutions, rigorous quality assurance, and a commitment to innovation, these suppliers enable manufacturers to achieve reliability, performance, and longevity in their products. As the electronics industry continues to evolve, the future of electronic encapsulation suppliers shines bright, promising continued growth, innovation, and success in safeguarding electronic components against the elements.

For more about protecting innovation: exploring the role of electronic encapsulation suppliers,you can pay a visit to DeepMaterial at https://www.pottingcompound.com/what-is-potting-and-encapsulation/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB