Shielding Electronics: Exploring the Dynamics of the Conformal Coating Market

- Electronic Potting Material Manufacturer

- June 18, 2024

- acrylic vs silicone conformal coating, coating heads adhesive application, conformal coating for electronics, conformal coating in electronics market, conformal coating overspray, conformal coatings for electronics, conformal coatings for electronics applications, conformal coatings market for automotive electronics, consumer electronics coating, consumer electronics coatings, electronics coating, electronics coating technologies, electronics coatings, epoxy coating for electrical insulation, epoxy conformal coating, epoxy powder coating for electrical insulation, high-temperature insulation coatings for transformers, insulating epoxy coating, nano coating electronics, nano coating for electronics, non conductive coating for electronics, non conductive coatings, uv conformal coating manufacture

Shielding Electronics: Exploring the Dynamics of the Conformal Coating Market

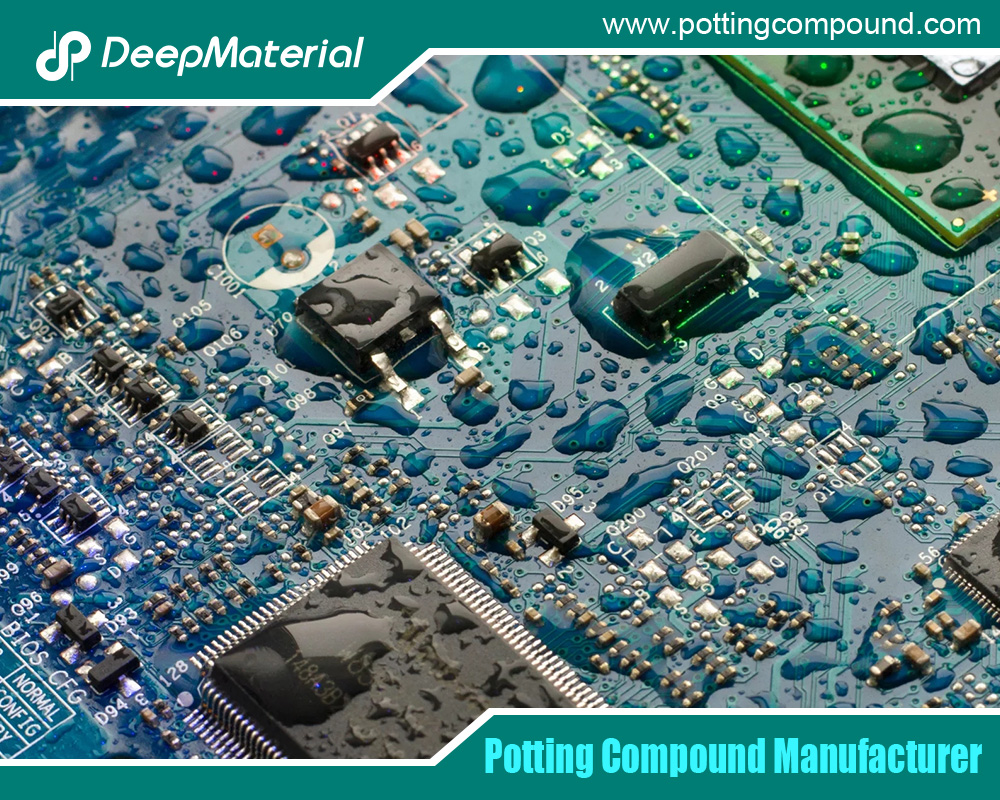

In the intricate world of electronics, safeguarding delicate components from harsh environmental conditions is paramount. Enter conformal coating, a specialized protective layer applied to electronic circuitry to enhance durability and reliability. As the demand for high-performance electronic devices continues to rise, so does the prominence of the conformal coating market. In this blog post, we delve into the nuances of this dynamic industry, exploring its growth drivers, key players, emerging trends, and prospects.

Understanding Conformal Coating: A Shield for Electronics

In the ever-evolving electronics industry, conformal coating protects electronic components from environmental factors, moisture, dust, and chemical contaminants. This paragraph delves into the nuances of conformal coating and its significance in safeguarding electronics, exploring its applications, benefits, and dynamics in the electronics market.

Applications and Importance:

Conformal coatings are applied to printed circuit boards (PCBs) and electronic assemblies to provide a protective barrier against many environmental stressors. Whether it’s consumer electronics, automotive systems, aerospace equipment, or industrial machinery, conformal coatings ensure the reliability and longevity of electronic devices by preventing corrosion, electrical short circuits, and performance degradation caused by harsh operating conditions.

Market Dynamics:

The conformal coating market in electronics is experiencing steady growth, driven by the increasing demand for reliable and durable electronic devices across various industries. As the complexity of electronic assemblies continues to rise, so does the need for advanced conformal coating solutions that can withstand extreme temperatures, vibrations, and chemical exposure. Market players are innovating to develop new formulations that offer enhanced protection while addressing environmental regulations and customer preferences for eco-friendly coatings.

Market Dynamics: Growth Drivers and Trends

Within the dynamic landscape of the electronics industry, the conformal coating market emerges as a vital segment, ensuring the longevity and reliability of electronic devices in various applications. Understanding the market dynamics, including growth drivers and emerging trends, provides valuable insights into the evolving needs of manufacturers and end-users alike.

- Rising Demand for Consumer Electronics: The proliferation of smartphones, tablets, wearables, and other consumer electronic devices fuels the demand for conformal coatings to protect sensitive electronic components from environmental factors such as moisture, dust, and temperature fluctuations.

- Advancements in Automotive Electronics: With the increasing integration of electronic systems in modern vehicles, the automotive industry represents a significant growth opportunity for conformal coating manufacturers. These coatings safeguard electronic components from harsh automotive environments, including exposure to heat, vibration, and chemicals.

- Expansion of Aerospace and Defense Applications: In the aerospace and defense sectors, conformal coatings are critical in enhancing the reliability and performance of electronic systems used in aircraft, missiles, and military equipment. As these industries continue to innovate and adopt advanced electronic technologies, the demand for specialized conformal coatings is expected to rise.

- Focus on Miniaturization and High-Performance Electronics: The trend towards miniaturization and the development of high-performance electronic devices drives the need for conformal coatings with enhanced properties, such as ultra-thin films, high dielectric strength, and superior thermal management capabilities.

- Growing Awareness of Environmental Regulations: Increasing awareness of environmental regulations and the need for eco-friendly solutions propel the demand for conformal coatings with low volatile organic compound (VOC) emissions and compliance with RoHS (Restriction of Hazardous Substances) directives.

- Shift towards Automated Application Processes: To improve efficiency and reduce costs, manufacturers are increasingly adopting automated application processes, such as selective coating and robotic spraying, for applying conformal coatings to electronic assemblies.

As the electronics industry continues to evolve, driven by technological advancements and changing consumer preferences, the conformal coating market is poised for steady growth. This is due to the imperative need for reliable protection and performance enhancement of electronic devices across diverse applications.

Types of Conformal Coatings and Their Applications

In the ever-expanding realm of electronics, applying conformal coatings is crucial to ensuring the durability, reliability, and longevity of electronic components and assemblies. Understanding the various types of conformal coatings available in the market and their specific applications is essential for manufacturers and end-users seeking optimal protection against environmental factors and mechanical stress.

- Silicone-Based Coatings: Silicone conformal coatings offer excellent flexibility and resistance to high temperatures, making them ideal for applications subjected to extreme heat or thermal cycling, such as automotive electronics, aerospace systems, and LED lighting.

- Acrylic-Based Coatings: Acrylic conformal coatings provide good moisture resistance, electrical insulation, and UV stability, making them suitable for general-purpose electronics, including consumer electronics, PCBs (Printed Circuit Boards), and industrial control systems.

- Polyurethane-Based Coatings: Polyurethane conformal coatings offer superior chemical resistance and mechanical protection, making them well-suited for harsh environments exposed to chemicals, solvents, and abrasion, such as automotive electronics, marine equipment, and outdoor telecommunications.

- Epoxy-Based Coatings: Epoxy conformal coatings provide excellent adhesion, hardness, and moisture barrier properties, making them suitable for high-reliability applications in aerospace, military, and medical electronics, where superior protection against moisture ingress and mechanical shock is critical.

- Parylene Coatings: Parylene conformal coatings offer ultra-thin, pinhole-free protection with exceptional chemical resistance and dielectric properties, making them ideal for delicate electronic components, medical devices, and MEMS (Microelectromechanical Systems) where precise, uniform coating coverage is required.

- UV-Curable Coatings: UV-curable conformal coatings offer rapid curing times and low volatile organic compound (VOC) emissions, making them environmentally friendly and suitable for high-volume manufacturing processes in consumer electronics, telecommunications, and automotive electronics.

By understanding the unique properties and applications of different types of conformal coatings, manufacturers and designers can select the most appropriate coating solution to meet their electronic assemblies’ specific performance requirements and environmental challenges, ensuring optimal reliability and longevity in diverse operating conditions.

Emerging Technologies and Innovations

As the electronics industry continues to evolve, the demand for advanced protection solutions has led to the emergence of innovative technologies in the conformal coating market. This paragraph explores some of the most promising emerging technologies and innovations shaping the landscape of conformal coatings in electronics, highlighting their potential to revolutionize electronic device protection.

Nano Coatings:

Nanocoatings represent a cutting-edge innovation in conformal coating technology, offering ultra-thin protective layers with exceptional performance properties. By leveraging nanotechnology, these coatings can achieve superior coverage and adhesion while minimizing material usage, making them ideal for compact electronic devices with densely packed components. Additionally, nano coatings exhibit enhanced resistance to moisture, chemicals, and abrasion, providing robust protection against a wide range of environmental stressors.

Self-Healing Coatings:

Self-healing coatings are another groundbreaking development in the conformal coating market. These coatings can automatically repair minor damages and scratches. These coatings contain microcapsules filled with healing agents that rupture upon damage, releasing materials that flow and fill in the affected areas, restoring the integrity of the coating. With self-healing capabilities, electronic devices coated with these innovative materials can maintain their protective barrier over time, prolonging their lifespan and reliability in harsh operating conditions.

Transparent Conductive Coatings:

Transparent conductive coatings combine the functionalities of conformal protection and electrical conductivity, enabling the coating of electronic devices without compromising their performance. These coatings, often based on conductive polymers or metal oxides, provide a transparent and electrically conductive layer that shields the underlying components while allowing for seamless touchscreens, displays, and sensor operations. With the increasing integration of electronics into everyday objects, transparent conductive coatings offer a versatile solution for protecting and enhancing the functionality of electronic devices in various applications.

Challenges and Opportunities Ahead

As the demand for electronic devices continues to surge, the conformal coating market faces a landscape rife with challenges and opportunities, driving innovation and adaptation within the industry.

- Rapid Technological Advancements: Keeping pace with rapid advancements in electronic technology poses a challenge for conformal coating manufacturers, who must develop coatings that meet evolving performance requirements.

- Environmental Regulations: Compliance with stringent environmental regulations presents challenges and opportunities for manufacturers to innovate eco-friendly coating solutions.

- Global Supply Chain Disruptions: Addressing disruptions in the global supply chain requires resilient strategies to ensure consistent access to raw materials and production capabilities.

- Emerging Applications: The expansion of electronic applications into new industries such as wearable technology, IoT (Internet of Things), and renewable energy presents opportunities for growth and diversification within the conformal coating market.

Conclusion

The conformal coating market is poised for significant growth as the demand for reliable and durable electronic devices escalates. Manufacturers can capitalize on emerging opportunities with technological advancements, innovative formulations, and a focus on sustainability. By navigating challenges and embracing collaboration, the future of the conformal coating market shines bright, promising enhanced protection and performance for electronic devices across various industries.

For more about shielding electronics: exploring the dynamics of the conformal coating market,you can pay a visit to DeepMaterial at https://www.pottingcompound.com/conformal-coating/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB