Silicone Potting Compounds for Electronics: A Comprehensive Guide to Protection and Performance

- Electronic Potting Material Manufacturer

- November 15, 2024

- Acrylic Conformal Coating, Connector Potting Compound, electronic potting compound, Flexible Potting Compound, Industrial Conformal Coating, LED Potting Compound, pcb conformal coating, PCB Potting Compound, polyurethane potting compound, Silicone Conformal Coating, Silicone Potting Compound, silicone potting compounds for electronic, silicone potting compounds for electronic china hotsale, silicone potting compounds for electronic china OEM, silicone potting compounds for electronic china wholesale, silicone potting compounds for electronic hotsale, silicone potting compounds for electronic OEM, silicone potting compounds for electronic wholesale, Urethane Conformal Coating, UV Cure Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating, waterproof potting compound

Silicone Potting Compounds for Electronics: A Comprehensive Guide to Protection and Performance

In the dynamic realm of electronics, the integrity and longevity of components are critical to ensuring reliable performance. With electronic devices’ increasing complexity and diverse environmental challenges, manufacturers and engineers constantly search for practical solutions to protect sensitive components. One of the most reliable methods is the use of silicone potting compounds. These materials provide an exceptional barrier against moisture, dust, chemicals, and mechanical stresses, enhancing the durability and reliability of electronic assemblies. This blog post will explore the properties, benefits, applications, and selection criteria of silicone potting compounds in detail, serving as a valuable resource for professionals in the electronics industry.

Understanding Silicone Potting Compounds

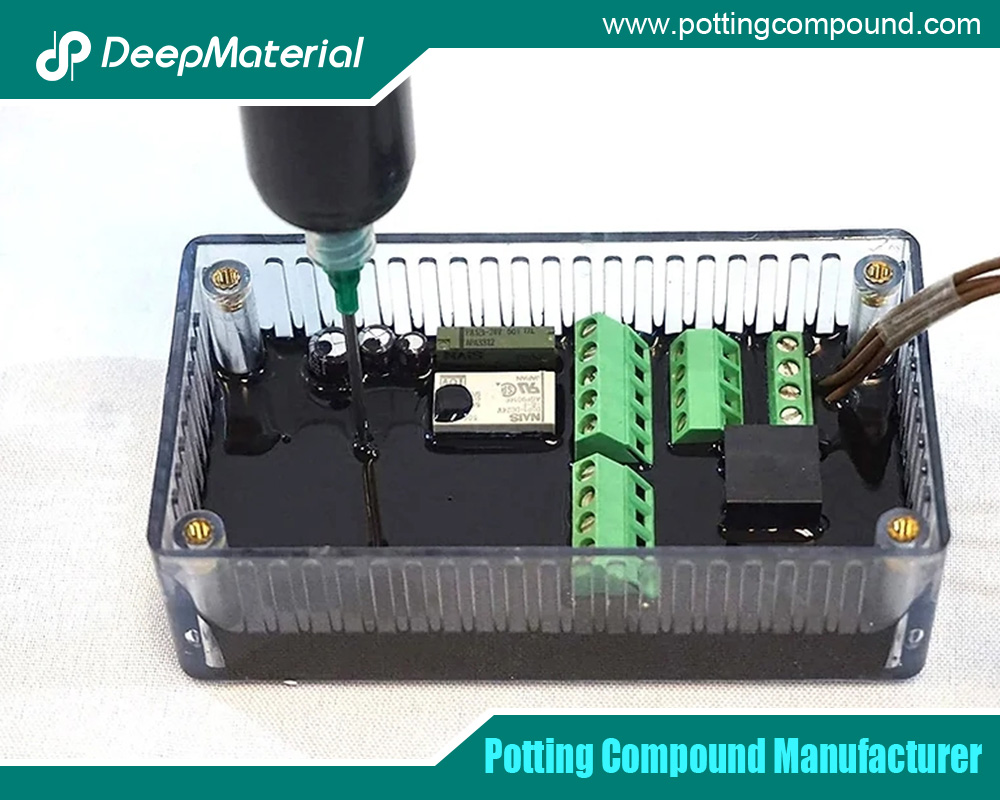

Silicone potting compounds are specialized materials that encapsulate and protect electronic components and assemblies. Made from silicone polymers, these compounds are often used in potting or encapsulation, where the compound is poured or injected around components to form a solid, protective layer. The result is a highly effective insulator shielding electronic parts from environmental factors, mechanical stress, and thermal fluctuations.

Key Properties

Silicone potting compounds possess several fundamental properties that make them ideal for electronic applications:

- Thermal Stability: They can withstand extreme temperatures without losing their integrity, making them suitable for high-heat environments.

- Chemical Resistance: These compounds resist degradation from various chemicals, ensuring they remain effective even in harsh environments.

- Flexibility: Silicone potting compounds maintain flexibility at low temperatures, which helps them absorb mechanical stress without cracking.

- Electrical Insulation:They provide excellent dielectric properties, preventing electrical shorts and enhancing overall device reliability.

- Moisture Resistance: Silicone potting compounds form a watertight seal protecting components from ingress.

Applications of Silicone Potting Compounds

Due to their versatility and protective properties, silicone potting compounds have widespread applications across various industries. Some notable applications include:

Consumer Electronics

- Smartphones and Tablets: Potting compounds protect sensitive circuit boards and components from moisture and dust, enhancing durability.

- Wearable Devices: Silicone compounds safeguard electronic components from sweat and environmental exposure in fitness trackers and smartwatches.

Automotive Electronics

- Sensors: Encapsulating sensors help prevent damage from vibrations, moisture, and extreme temperatures.

- Control Units: Potting compounds protect control units from environmental factors, ensuring reliable vehicle performance.

Industrial Equipment

- Power Supplies: Silicone potting compounds shield power supply components from dust and moisture, ensuring stable operation.

- Control Systems: Encapsulated control systems are less susceptible to external environmental influences, improving overall efficiency.

Medical Devices

- Diagnostic Equipment: Potting compounds protect sensitive electronics in medical devices, ensuring reliable operation in critical applications.

- Implantable Devices: Silicone potting compounds are essential in encapsulating electronics for implantable devices, providing biocompatibility and moisture resistance.

Benefits of Silicone Potting Compounds

The adoption of silicone potting compounds in electronic applications offers numerous advantages that contribute to enhanced device performance and longevity:

Enhanced Protection

- Moisture Barrier:Prevents water ingress, which can lead to corrosion and short circuits in electronic components.

- Dust and Dirt Resistance:Keeps contaminants away, ensuring optimal functioning of electronic parts.

- UV Resistance: Some silicone formulations protect against UV radiation, making them suitable for outdoor electronics.

Improved Performance

- Thermal Management: Helps dissipate heat from electronic components, enhancing efficiency and preventing overheating.

- Mechanical Support: Reduces the risk of damage from vibrations and shocks, making devices more robust and reliable.

Cost-Effectiveness

- Reduced Failure Rates:Enhanced protection and reliability lead to lower warranty claims and manufacturer replacement costs.

- Longer Lifespan: Devices using silicone potting compounds often experience extended operational life, providing a better return on investment.

Environmental Sustainability

- Non-toxic Formulations:Many silicone potting compounds are non-toxic and environmentally friendly, making them safer for various applications.

- Recyclability: Certain silicone products can be recycled, contributing to sustainability efforts within the electronics industry.

Choosing the Right Silicone Potting Compound

Selecting the appropriate silicone potting compound for a specific application involves considering various factors:

Cure Time

- Fast-Curing Formulations: Suitable for applications requiring quick processing times and minimal downtime.

- Slow-Curing Formulations:Ideal for larger applications where extended working time is beneficial.

Viscosity

- Low Viscosity:Preferred for applications requiring easy flow into intricate designs and gaps.

- High Viscosity: Suitable for applications where the material needs to hold its shape during the curing process.

Thermal Conductivity

- High Thermal Conductivity: Essential for applications where heat dissipation is crucial, such as power electronics.

- Low Thermal Conductivity: This may be adequate for less demanding applications.

Electrical Properties

- Dielectric Strength: Ensure the chosen compound meets the required dielectric strength for electrical insulation.

- Volume Resistivity: Select compounds with high volume resistivity to prevent electrical leakage.

Environmental Resistance

- Chemical Resistance:Choose compounds that can withstand specific chemicals present in the operating environment.

- Temperature Range:Ensure the potting compound can operate effectively within the expected temperature range.

Application Techniques for Silicone Potting Compounds

The method of applying silicone potting compounds can vary depending on the specific application and production scale:

Manual Dispensing

- Ideal for Small-Scale Projects:Useful for prototypes and small batches where precision application is necessary.

- Flexibility: Allows adjustments during the application process, making it suitable for unique designs.

Automated Dispensing

- Mass Production:Ensures consistency and efficiency in larger production runs.

- Precision: Automated systems can deliver precise amounts of material, reducing waste.

Injection Molding

- Complex Shapes:A method suitable for complex assemblies requiring complete encapsulation.

- Uniform Application: Ensures even coverage and consistent results.

Safety Considerations

When working with silicone potting compounds, safety precautions should be followed to ensure a safe working environment:

Personal Protective Equipment (PPE)

- Gloves:Wear protective gloves to prevent skin contact with uncured compounds.

- Goggles:Use safety goggles to protect eyes from splashes during mixing and application.

- Respirators: In poorly ventilated areas, wear a respirator to avoid inhaling fumes.

Ventilation

- Adequate Airflow:Ensure proper ventilation in the workspace to dissipate fumes released during mixing and curing.

Material Disposal

- Follow Regulations:Adhere to local regulations for the disposal of silicone compounds and related materials.

- Recycling Options: Explore recycling options for unused or cured materials where applicable.

Troubleshooting Common Issues

Despite the many advantages of silicone potting compounds, challenges may arise during application or performance. Here are some common issues and troubleshooting tips:

Bubbles in the Potting Compound

- Cause: Trapped air during mixing or application.

- Solution:Degas the compound in a vacuum chamber before use or apply the material slowly to minimize air entrapment.

Incomplete Curing

- Cause:Insufficient curing time or incorrect temperature.

- Solution:Ensure that the specified curing conditions are met and allow adequate Time for the compound to cure completely.

Cracking or Shrinkage

- Cause:Rapid temperature changes or incorrect formulation.

- Solution: Use a silicone compound with appropriate thermal properties for the application and avoid exposing the cured product to sudden temperature fluctuations.

Adhesion Issues

- Cause:Incompatibility with substrate materials or insufficient surface preparation.

- Solution:Ensure proper surface preparation and cleaning before applying the potting compound. Select formulations specifically designed for the substrate materials used.

Conclusion

Silicone potting compounds are indispensable in the electronics industry, offering a comprehensive solution for protecting components and enhancing device performance. Their unique properties, including thermal stability, flexibility, and excellent electrical insulation, make them ideal for various applications, from consumer electronics to medical devices. By understanding the benefits, selection criteria, application techniques, and safety considerations associated with silicone potting compounds, manufacturers and engineers can make informed decisions that improve the reliability and longevity of electronic devices.

For more about choosing the silicone potting compounds for electronics: a comprehensive guide to protection and performance, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB