The Comprehensive Guide to Epoxy Potting Compound Manufacturers

- Electronic Potting Material Manufacturer

- October 23, 2024

- acrylic vs silicone conformal coating, Automotive potting material manufacturers, Benefits of Potting Electronics, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, conformal coating, conformal coating electronics, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating material, conformal coating silicone, Connector Potting Compound, custom automated electronics potting, customize china electronic potting silicone supplier, deepmaterial PCB Potting, deepmaterial potting compound, electrical potting compound, Electronic Encapsulant Potting Compound, Electronic Epoxy Encapsulant Potting Compound, Electronic Epoxy Potting Compound, epoxy potting compound, epoxy potting compound manufacturer, epoxy potting compound manufacturers, epoxy potting glue, epoxy potting manufacturer, potting compound manufacturer

The Comprehensive Guide to Epoxy Potting Compound Manufacturers

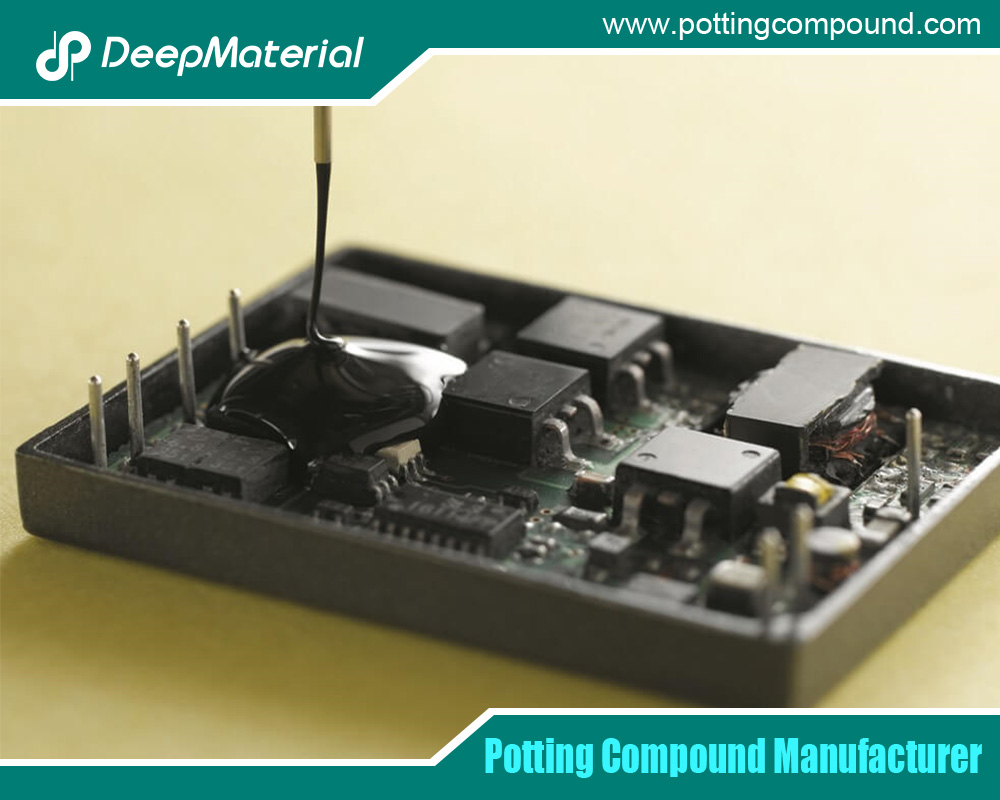

Epoxy potting compounds are essential materials in the electronics industry, providing robust protection for sensitive components against environmental factors, mechanical stress, and electrical interference. These compounds are widely used in various applications, from consumer electronics to aerospace systems, owing to their excellent adhesion, thermal stability, and chemical resistance. As the demand for reliable electronic devices continues to rise, the role of epoxy potting compound manufacturers becomes increasingly important. This blog post will explore the key players in the market, their products, applications, and considerations when choosing a manufacturer.

Understanding Epoxy Potting Compounds

Epoxy potting compounds are thermosetting polymers composed of a resin and a hardener that, when mixed, cure into a durable material. These compounds, known for their exceptional adhesion, thermal stability, and chemical resistance, protect electronic components against environmental factors, mechanical stress, and electrical interference.

What are Epoxy Potting Compounds?

Epoxy potting compounds are thermosetting polymers that, when cured, form a solid and durable material. They are typically composed of two components: a resin and a hardener. These components undergo a chemical reaction when mixed, resulting in a hardened, thermoset material with excellent mechanical properties.

Critical Properties of Epoxy Potting Compounds

Epoxy potting compounds are favored for their unique properties, which include:

- High Strength:Provides excellent mechanical support and protection.

- Thermal Stability:Can withstand high temperatures without degrading.

- Chemical Resistance: Resists solvents, oils, and other chemicals.

- Electrical Insulation: Offers superior dielectric strength, preventing electrical failures.

- Low Shrinkage: Minimal volume change during curing, ensuring a tight fit around components.

The Role of Epoxy Potting Compound Manufacturers

Epoxy potting compound manufacturers play a critical role in the electronics industry by producing high-quality materials that protect sensitive components. Their expertise ensures that these compounds meet stringent performance standards, addressing factors like durability, thermal stability, and chemical resistance, essential for reliable electronic devices across various applications.

Importance of Choosing the Right Manufacturer

The quality and performance of epoxy potting compounds heavily depend on the manufacturer. Choosing a reputable manufacturer ensures that the products meet industry standards and specifications. Key factors to consider when selecting a manufacturer include:

- Reputation and Experience:Established manufacturers often have a proven quality and reliability track record.

- Product Range: A diverse range of products allows for better selection based on specific application needs.

- Technical Support: Manufacturers that offer technical assistance can help customers optimize the use of their products.

- Customization Options:Customizing formulations based on unique requirements can be beneficial.

Applications of Epoxy Potting Compounds

Consumer Electronics

Epoxy potting compounds are widely used in consumer electronics to protect against moisture, dust, and mechanical stress. Applications include:

- Smartphones:Protecting circuit boards and components from environmental hazards.

- Wearable Devices:Ensuring durability and reliability in fitness trackers and smartwatches.

Automotive Industry

In the automotive sector, epoxy potting compounds protect electronic components from harsh conditions, including temperature fluctuations and vibration. Applications include:

- Sensor Encapsulation: Safeguarding sensors from moisture and debris.

- Electronic Control Units (ECUs):Providing mechanical support and protection against environmental factors.

Aerospace and Defense

The aerospace industry demands high-performance materials that can withstand extreme conditions. Epoxy potting compounds are used in:

- Avionics Systems:Protecting sensitive electronic components from moisture and shock.

- Satellite Electronics:Ensuring reliability in space applications.

Medical Devices

In the medical field, epoxy potting compounds play a vital role in ensuring the reliability and safety of electronic devices. Applications include:

- Implantable Devices:Protecting electronics from bodily fluids and ensuring biocompatibility.

- Diagnostic Equipment: Providing insulation and protection in various medical instruments.

Industrial Equipment

Epoxy potting compounds are widely used in industrial applications to protect electronic components in harsh environments. Applications include:

- Control Systems:Protect sensitive electronics from dust, moisture, and temperature extremes.

- Motors and Actuators:Enhancing reliability in rugged applications.

Advantages of Epoxy Potting Compounds

Epoxy potting compounds offer numerous benefits for electronic applications, including:

- Enhanced Protection: Safeguards electronic components from moisture, dust, and environmental hazards.

- Mechanical Stability:Provides excellent mechanical support and reduces the risk of damage from vibrations and shocks.

- Electrical Insulation:Offers superior dielectric strength, minimizing the risk of electrical failures.

- Versatility:This can be customized for various applications and environments, ensuring optimal performance.

Disadvantages of Epoxy Potting Compounds

While epoxy potting compounds have many advantages, they also come with some drawbacks:

- Rework Difficulty:Once components are potted, repairing or replacing them can be challenging and time-consuming.

- Weight: Some epoxy compounds can add significant weight to devices, which may not be suitable for all applications.

- Cure Time: Depending on the formulation, curing times can vary, impacting production schedules.

Factors to Consider When Choosing a Manufacturer

When selecting an epoxy potting compound manufacturer, consider the following factors:

Quality and Performance

Ensure that the manufacturer adheres to industry standards and produces high-quality products. Look for certifications and testing procedures that guarantee product performance.

Customization Options

Choose a manufacturer that offers customizable formulations to meet your specific requirements. This flexibility can enhance the performance of the potting compound in your application.

Technical Support

Opt for manufacturers that provide strong technical support, including product selection, application, and troubleshooting assistance. This support can be invaluable in optimizing the use of their products.

Delivery and Supply Chain

Consider the manufacturer’s ability to deliver products on time and manage supply chain logistics. A reliable supplier can help maintain production schedules and reduce downtime.

Pricing

Evaluate pricing structures and ensure that they align with your budget. While cost is a factor, prioritize quality and performance over the lowest price.

Future Trends in Epoxy Potting Compounds

Eco-Friendly Formulations

With increasing environmental awareness, manufacturers are developing eco-friendly epoxy potting compounds that minimize ecological impact. These formulations may be biodegradable or made from renewable resources, providing a sustainable option for electronic applications.

Advanced Thermal Management

The demand for potting compounds with advanced thermal management capabilities is growing as electronic devices become more powerful. Manufacturers are developing materials that efficiently dissipate heat while maintaining mechanical stability, which is essential for high-performance applications.

Smart Potting Solutions

Innovations in innovative materials that can respond to environmental changes are emerging. These materials can change properties based on temperature or humidity, providing dynamic protection for electronic components.

Enhanced Adhesion Technologies

New formulations are being developed to enhance adhesion between potting compounds and substrates, ensuring better protection and reducing the risk of delamination.

Conclusion

Epoxy potting compounds are essential materials in the electronics industry, providing vital protection and support for sensitive components. Understanding the leading manufacturers, their products, and the factors to consider when choosing a supplier can significantly impact the performance and reliability of electronic devices. As technology advances, the importance of high-quality epoxy potting compounds will only continue to grow.

For more about choosing the comprehensive guide to epoxy potting compound manufacturers, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB