Understanding Circuit Board Potting Compound: Types, Applications, and Considerations

- Electronic Potting Material Manufacturer

- July 31, 2024

- circuit board potting compound, Connector Potting Compound, deepmaterial potting compound, electrical potting compound, electronic encapsulant potting compounds, electronic epoxy encapsulant potting compounds, electronic potting compound, Electronic Potting Compounds Manufacturer, encapsulant potting compounds, Encapsulants and Potting Compounds Suppliers, epoxy encapsulant potting compounds, epoxy potting compound, epoxy potting compound manufacturers, Flexible Potting Compound, LED Potting Compound, PCB Potting Compound, PCB Potting Compound and Conformal Coating Adhesive, PCB potting compounds, polyurethane potting compound, potting compound, uv potting compound

Understanding Circuit Board Potting Compound: Types, Applications, and Considerations

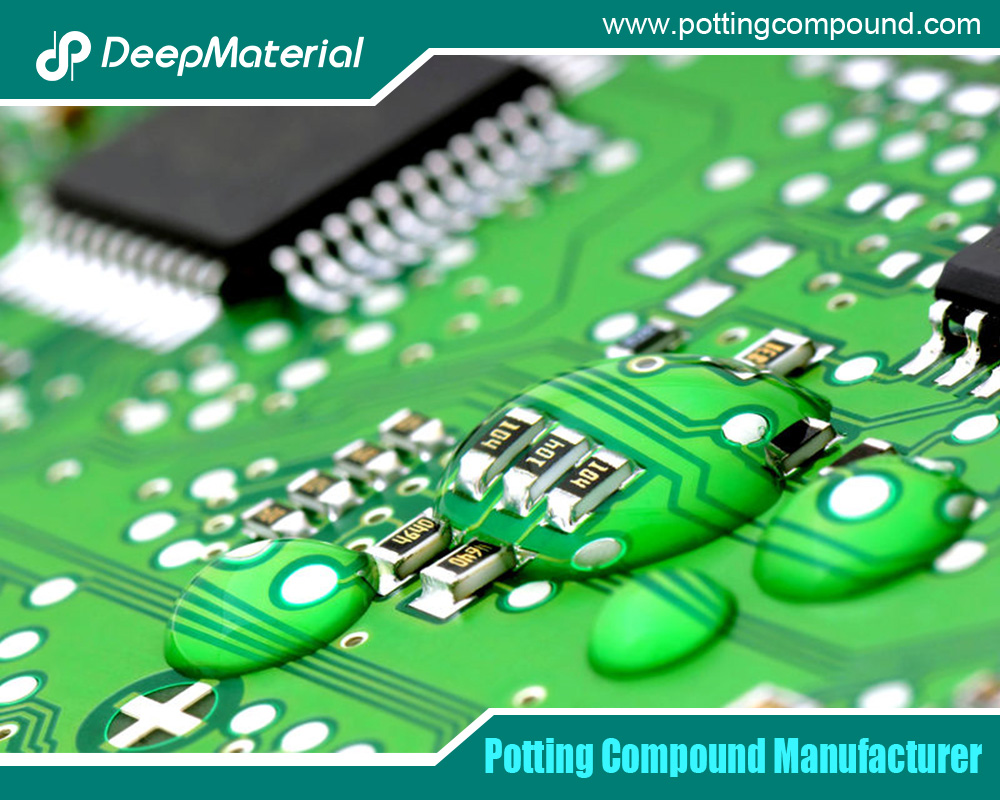

In the realm of electronic devices and systems, reliability and durability are paramount. Circuit board potting compounds play a crucial role in ensuring the longevity and performance of electronics by protecting environmental factors, mechanical stress, and electrical interference. This comprehensive guide explores circuit board potting compounds’ types, applications, benefits, and considerations, shedding light on their significance in various industries.

Circuit board potting compounds, often referred to simply as potting compounds, are materials used to encapsulate electronic components. This encapsulation serves several critical purposes: it protects sensitive electronics from moisture, dust, chemicals, and mechanical shock, enhances thermal management, improves electrical insulation, and increases overall reliability. Potting compounds are applied to circuit boards and other electronic assemblies by filling the gaps around components to form a protective barrier.

Types of Circuit Board Potting Compounds

Epoxy Resin Compounds

Epoxy resin potting compounds are the most widely used due to their excellent mechanical properties and adhesion capabilities. These compounds offer high strength, good chemical resistance, and superb protection against moisture and environmental contaminants. Epoxy resins cure into a hard, rigid material, making them suitable for applications where robust protection is required, such as in industrial electronics, automotive components, and outdoor equipment.

Properties and Benefits:

- High mechanical strength and stiffness

- Superior adhesion to various substrates

- Excellent chemical and moisture resistance

Applications:

- Industrial control systems

- Automotive electronic control units (ECUs)

- Outdoor LED lighting fixtures

Silicone Potting Compounds

Silicone potting compounds are valued for their flexibility, thermal stability, and resistance to extreme temperatures. They remain elastic over various temperatures, making them ideal for critical thermal cycling and flexibility applications. Silicone potting compounds also exhibit good resistance to moisture and UV radiation, making them suitable for outdoor and harsh environment applications.

Characteristics and Advantages:

- Flexibility and elasticity

- High thermal stability

- UV and weather resistance

Applications:

- Solar inverters

- Outdoor sensors and actuators

- Aerospace electronics

Polyurethane Potting Compounds

Polyurethane potting compounds offer a balance between flexibility and toughness. They provide excellent electrical insulation properties and can withstand mechanical stress and vibrations. Polyurethanes are known for their excellent chemical resistance and ease of processing, making them suitable for applications requiring a combination of mechanical robustness and electrical performance.

Features and Benefits:

- Flexibility and impact resistance

- Good chemical resistance

- Vibration and shock absorption

Applications:

- Consumer electronics

- Medical devices

- Renewable energy systems

Applications of Circuit Board Potting Compounds

Circuit board potting compounds are widely used across various industries where electronics are deployed in demanding environments. The applications span from consumer electronics to industrial automation, each leveraging the unique properties of potting compounds to enhance product reliability and performance.

Electronics and Electrical Equipment:

- Protecting sensitive components from moisture and contaminants

- Improving resistance to mechanical stress and vibrations

Automotive Industry:

- Enhancing the reliability of ECUs and sensors

- Thermal management in automotive electronics

Aerospace and Defense:

- Safeguarding electronics from extreme temperatures and vibrations

- Meeting stringent safety and reliability standards

Renewable Energy:

- Ensuring the durability of electronics in solar inverters and wind turbines

- Protecting against outdoor environmental conditions

Consumer Electronics:

- Improving water resistance in smartphones and wearables

- Extending product lifespan through enhanced protection

Benefits of Using Potting Compounds

Using circuit board potting compounds offers several key benefits that contribute to the reliability and longevity of electronic devices and systems.

Environmental Protection:

- Sealing electronics against moisture, dust, and chemicals

- Preventing corrosion and short circuits in harsh environments

Enhanced Thermal Management:

- Facilitating heat dissipation from electronic components

- Maintaining optimal operating temperatures for improved performance

Mechanical Protection:

- Absorbing mechanical shocks and vibrations

- Enhancing durability and resistance to physical impact

Electrical Insulation:

- Preventing electrical leakage and interference

- Ensuring safety and compliance with regulatory standards

Considerations When Choosing Potting Compounds

Selecting the suitable circuit board potting compound involves evaluating several factors to ensure compatibility with the specific application requirements and environmental conditions.

Operating Conditions:

- Temperature range and environmental exposure (e.g., humidity, UV exposure)

- Chemical resistance to substances present in the operating environment

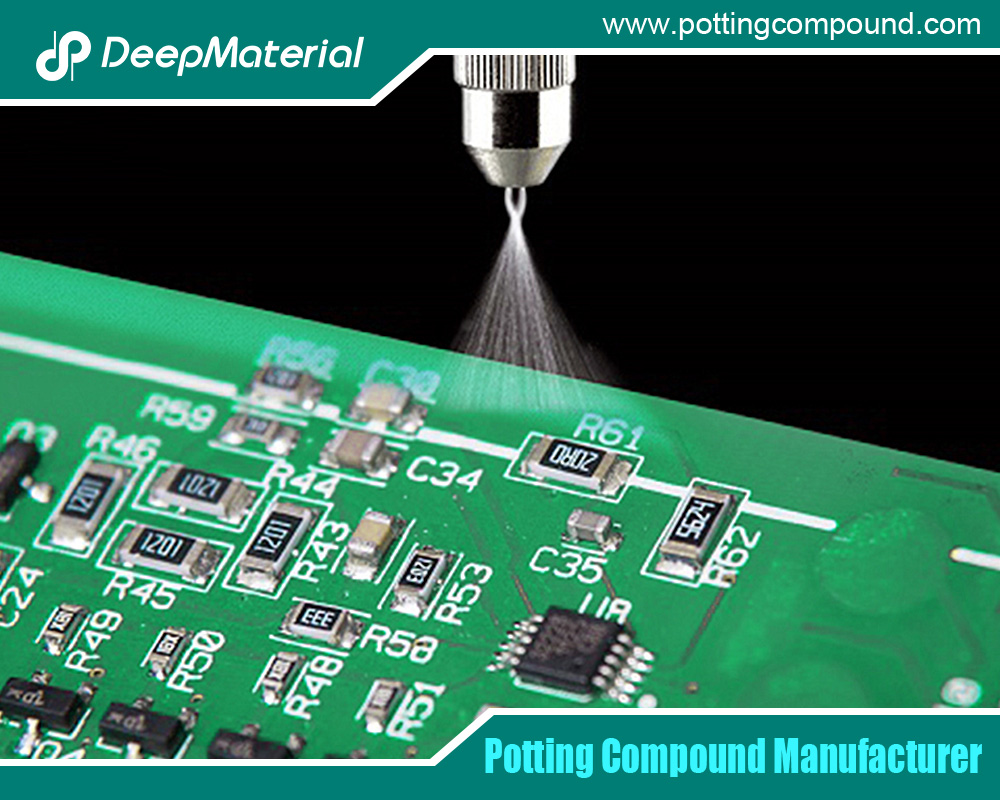

Curing and Processing Requirements:

- Pot life and cure time considerations

- Compatibility with manufacturing processes (e.g., automated dispensing, manual potting)

Mechanical Properties:

- Desired level of flexibility or rigidity based on application needs

- Impact on assembly, maintenance, and repairability of electronic assemblies

Cost and Long-Term Durability:

- Total cost of ownership analysis, considering initial material costs and maintenance requirements

- Expected lifespan and reliability impact on product lifecycle management

Future Trends

Looking ahead, advancements in material science and manufacturing technologies are expected to enhance further the capabilities and applications of circuit board potting compounds. Future trends may include:

- Developments in bio-based resins for environmental sustainability.

- Improved nanotechnology for enhanced thermal conductivity.

- Innovations in flexible potting materials to meet the evolving needs of wearable electronics and IoT devices.

Bio-based Resins: With increasing emphasis on environmental sustainability, there is a growing interest in bio-based resins derived from renewable sources such as plant oils or bio-waste. These resins offer similar or even improved properties compared to traditional synthetic resins while reducing the environmental footprint of electronic products.

Nanotechnology: Integrating nanomaterials into potting compounds holds promise for enhancing thermal conductivity and mechanical strength. Nanoparticles such as graphene or carbon nanotubes can be incorporated into potting materials to improve heat dissipation and reinforce mechanical properties without compromising flexibility.

Flexible Potting Materials: As electronics become more integrated into flexible substrates and wearable devices, there is a demand for potting compounds that can conform to irregular shapes and withstand repeated bending and stretching. Flexible potting materials based on elastomers or silicone blends are being developed to meet these requirements.

Smart Potting Compounds: The evolution of IoT devices and intelligent electronics necessitates potting compounds that can protect and interact with embedded sensors and actuators. Innovative potting materials may include self-healing properties to repair minor damage or sensors to monitor environmental conditions.

Advanced Manufacturing Techniques: Innovations in dispensing and curing technologies are streamlining the application of potting compounds in manufacturing processes. Automated dispensing systems equipped with precision control and real-time monitoring capabilities enhance consistency and efficiency in potting operations.

Regulatory Compliance: As regulations governing the use of hazardous substances in electronics (such as RoHS and REACH directives) continue to evolve, there is a focus on developing potting compounds that comply with these stringent requirements while maintaining high-performance standards.

Conclusion

The landscape of circuit board potting compounds is evolving rapidly, driven by technological advancements, environmental considerations, and the expanding applications of electronics in various industries. By understanding the types, applications, benefits, and considerations associated with potting compounds, engineers and manufacturers can make informed decisions to optimise electronic products’ reliability, durability, and performance.

As industries continue to innovate and demand higher levels of reliability from electronic devices, circuit board potting compounds will remain pivotal in safeguarding electronics against environmental factors, enhancing thermal management, improving mechanical resilience, and ensuring electrical insulation. By staying abreast of emerging trends and leveraging advancements in material science and manufacturing technologies, stakeholders in the electronics industry can pave the way for future innovations in potting compound technology.

In conclusion, the ongoing evolution of circuit board potting compounds underscores their critical importance in the reliability and functionality of modern electronics. As technology advances and market demands evolve, the development and application of advanced potting materials will continue to play a crucial role in shaping the future of electronic devices across industries.

For more about understanding circuit board potting compound: types, applications, and considerations, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB