Understanding Electrical Potting Compounds: Properties, Applications, and Benefits

- Electronic Potting Material Manufacturer

- December 10, 2024

- Acrylic Conformal Coating, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting compound, Connector Potting Compound, deepmaterial potting compound, electric motor potting compound china hotsale, electric motor potting compound china OEM, electric motor potting compound china wholesale, electric motor potting compound factory hotsale, electrical potting compound, electrical potting compounds, Electronic Conformal Coating, Electronic Epoxy Potting Compound, electronic potting compound, epoxy conformal coating, epoxy potting compound, epoxy potting compound manufacturer, Flexible Potting Compound, Industrial Conformal Coating, LED Potting Compound, pcb conformal coating, PCB Potting Compound, polyurethane potting compound, Silicone Conformal Coating, Silicone Potting Compound, Urethane Conformal Coating, UV Cure Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating, waterproof potting compound

Understanding Electrical Potting Compounds: Properties, Applications, and Benefits

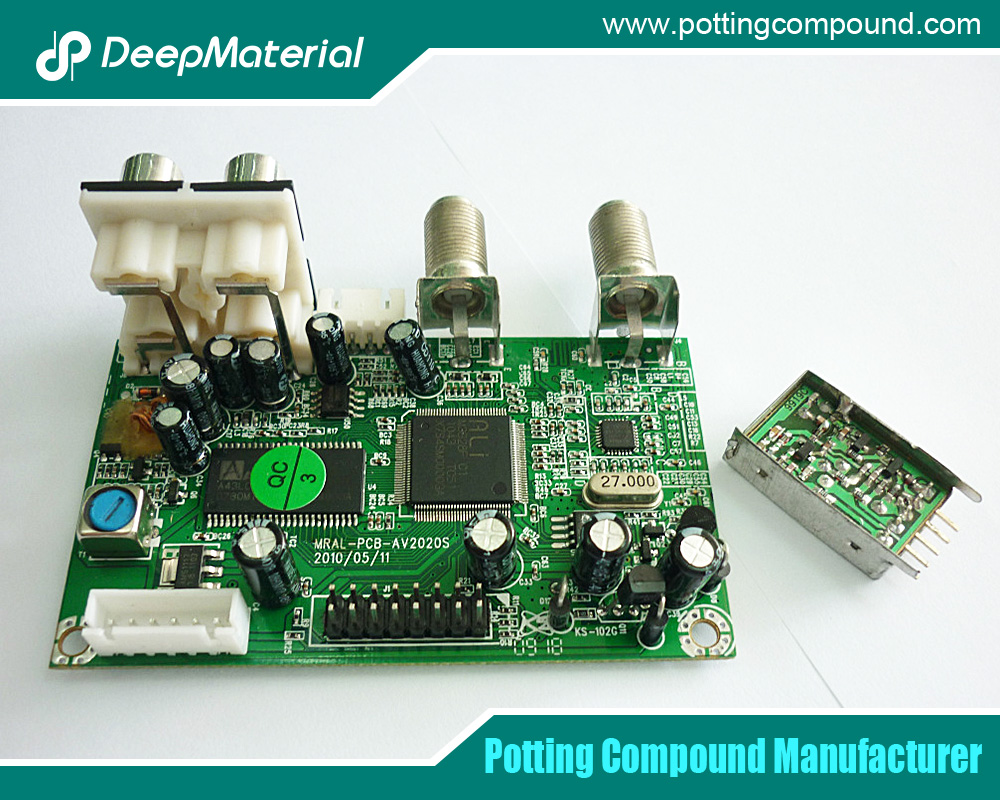

In the realm of electronics, ensuring the longevity and reliability of components is paramount. One method of achieving this is through the use of electrical potting compounds. These specialized materials serve as protective barriers, safeguarding electronic components from environmental factors such as moisture, dust, and mechanical stress. This article delves into the intricacies of electrical potting compounds, exploring their properties, applications, and the myriad benefits they offer in various industries.

What are Electrical Potting Compounds?

Electrical potting compounds are viscous materials encapsulating electronic components, providing insulation, mechanical protection, and environmental sealing. They are typically made from polymer resins, either thermosetting or thermoplastic. The choice of material depends on the application’s specific requirements, such as thermal conductivity, electrical insulation, and flexibility.

Critical Characteristics of Electrical Potting Compounds

- Chemical Composition: Composed mainly of epoxy, polyurethane, silicone, or polyester resins.

- Viscosity:Available in varying viscosities, affecting their ease of application and penetration into components.

- Curing Time: Different compounds have different curing times, influencing production speed.

- Thermal Stability:Must withstand various temperatures without degrading.

- Electrical Insulation:Essential for preventing electrical shorts and ensuring reliable operation.

Types of Electrical Potting Compounds

Several types of electrical potting compounds exist, each designed to meet specific performance criteria. Understanding the differences among these types is crucial for selecting the right one for a given application.

1. Epoxy Potting Compounds

- Features: High mechanical strength, excellent adhesion, and thermal stability.

- Applications:Ideal for harsh environments, often used in automotive and aerospace electronics.

2. Polyurethane Potting Compounds

- Features: Flexible, with good impact resistance and chemical resistance.

- Applications: Common in applications where vibration or thermal expansion is a concern.

3. Silicone Potting Compounds

- Features:Outstanding flexibility, temperature resistance, and moisture resistance.

- Applications: Widely used in high-reliability applications, such as medical devices and consumer electronics.

4. Polyester Potting Compounds

- Features:Good mechanical properties and moisture resistance.

- Applications:Often used in less demanding environments compared to epoxy and silicone.

The Potting Process: Steps and Considerations

Applying electrical potting compounds involves steps designed to ensure proper encapsulation and protection of the electronic components. Below are the general steps involved in the potting process:

Step 1: Preparation

- Cleaning: Thoroughly clean the components to remove dust, grease, or other contaminants.

- Drying: Ensure all components are dehydrated to avoid trapping moisture during potting.

Step 2: Mixing

- Proportioning: Accurately measure and mix the resin and hardener (if applicable) according to manufacturer specifications.

- Degassing: Remove air bubbles from the mixture, which can compromise the integrity of the potting.

Step 3: Application

- Pouring: Carefully pour the potting compound over the components, ensuring even distribution.

- Vacuum Impregnation: In some cases, a vacuum is applied to fill voids and ensure complete coverage.

Step 4: Curing

- Time and Temperature:Allow the compound to cure as per specifications, which can vary significantly depending on the type of material.

- Post-Cure Processing:Some compounds may require additional heating to enhance their properties.

Advantages of Using Electrical Potting Compounds

Utilizing electrical potting compounds offers many benefits, particularly in enhancing the performance and durability of electronic devices. Here are some key advantages:

Environmental Protection

- Moisture Barrier: Prevents water ingress, which can lead to corrosion and failure of components.

- Dust and Contaminant Shield: Protects sensitive electronics from dust and other contaminants that can disrupt function.

Mechanical Stability

- Vibration Resistance: Absorbs mechanical shocks and vibrations, reducing the risk of component damage.

- Thermal Expansion Management:Accommodates changes in size due to temperature fluctuations.

Improved Electrical Performance

- Insulation Properties:Enhances dielectric strength, reducing the risk of electrical shorts.

- Thermal Conductivity:Some compounds help dissipate heat, which is crucial for maintaining optimal operating temperatures.

Enhanced Product Life

- Longer Lifespan: Potting compounds can significantly extend the life of electronic devices by protecting them against environmental and mechanical stresses.

- Reliability:Increases the reliability of devices in critical applications such as medical and aerospace systems.

Applications Across Industries

Electrical potting compounds find applications in diverse industries, showcasing their versatility and adaptability.

Automotive Industry

- Use Cases: Protects electronic control units, sensors, and connectors from harsh conditions.

- Benefits:Ensures reliability and longevity in environments with extreme temperatures and moisture.

Aerospace and Defense

- Use Cases: Encapsulates avionics, communication systems, and critical components.

- Benefits:Meets rigorous standards for reliability and performance in demanding conditions.

Consumer Electronics

- Use Cases: Commonly used in smartphones, laptops, and other portable devices.

- Benefits: Protects against moisture and enhances durability.

Medical Devices

- Use Cases: Protects sensitive electronic components in devices like pacemakers and diagnostic equipment.

- Benefits:Ensures reliability and patient safety.

Industrial Equipment

- Use Cases: Used in manufacturing equipment sensors, controls, and circuits.

- Benefits: Reduces downtime and maintenance costs by enhancing reliability.

Considerations for Selecting Electrical Potting Compounds

Several factors should be considered when selecting the appropriate electrical potting compound to ensure optimal performance and compatibility with the intended application.

Operating Environment

- Temperature Range: Determine the temperature extremes the device will experience.

- Humidity Levels: Consider the moisture levels to ensure adequate protection against corrosion.

Mechanical Requirements

- Vibration Exposure:Assess the potential for mechanical shocks and vibrations affecting component integrity.

- Thermal Expansion: Understand how the materials will respond to temperature changes.

Electrical Properties

- Dielectric Strength: Choose compounds with sufficient insulation properties to prevent electrical failures.

- Thermal Conductivity: Consider the need for heat dissipation in high-power applications.

Curing Time and Method

- Production Efficiency: Factor in the curing time to maintain production schedules.

- Curing Method: Ensure compatibility with existing manufacturing processes, such as ambient or heat curing.

Cost Considerations

- Budget Constraints:Balance performance requirements with budgetary limits.

- Long-Term Savings: Consider the cost benefits of extended product lifespan and reduced maintenance.

Future Trends in Electrical Potting Compounds

As technology continues to evolve, so will the formulations and applications of electrical potting compounds. Here are some anticipated trends in this field:

Green and Sustainable Materials

- Development of Eco-Friendly Compounds:Increasing demand for environmentally friendly materials that reduce environmental impact.

- Biodegradable Options:Research into biodegradable compounds that maintain performance while being less harmful to the Environment.

Advanced Formulations

- Nano-Enhanced Materials:Incorporation of nanomaterials to improve performance characteristics, such as thermal and electrical conductivity.

- Innovative Potting Compounds: Development of materials that can change properties in response to environmental stimuli, enhancing functionality.

Increased Automation in Application

- Robotic Application Methods: Automated systems are adopted for the precision application of potting compounds.

- Monitoring Technologies: Use of sensors to monitor the curing process for improved consistency and quality control.

Conclusion

Electrical potting compounds play a critical role in the reliability and longevity of electronic devices across various industries. Their ability to provide environmental protection, mechanical stability, and enhanced electrical performance makes them indispensable in modern electronics. As technology advances, we can expect further innovations in the formulations and applications of these compounds, leading to even more effective solutions for protecting sensitive components. By understanding the properties, types, and benefits of electrical potting compounds, manufacturers can make informed decisions that enhance the performance and durability of their products.

For more about understanding electrical potting compounds: properties, applications, and benefits, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB