Understanding Epoxy Potting Compound Manufacturers: What You Need to Know

- Electronic Potting Material Manufacturer

- December 17, 2024

- Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting compound, circuit board potting compound china hotsale, circuit board potting compound china OEM, circuit board potting compound china wholesale, circuit board potting compound factory hotsale, circuit board potting compound factory OEM, circuit board potting compound factory wholesale, circuit board potting compound hotsale, circuit board potting compound wholesale, circuit board potting compounds, Connector Potting Compound, deepmaterial potting compound, electric motor potting compound, electric motor potting compound china hotsale, electric motor potting compound china OEM, electric motor potting compound factory hotsale, electric motor potting compound factory OEM, epoxy potting compound manufacturer, epoxy potting compound manufacturer hotsale, epoxy potting compound manufacturer wholesale

Understanding Epoxy Potting Compound Manufacturers: What You Need to Know

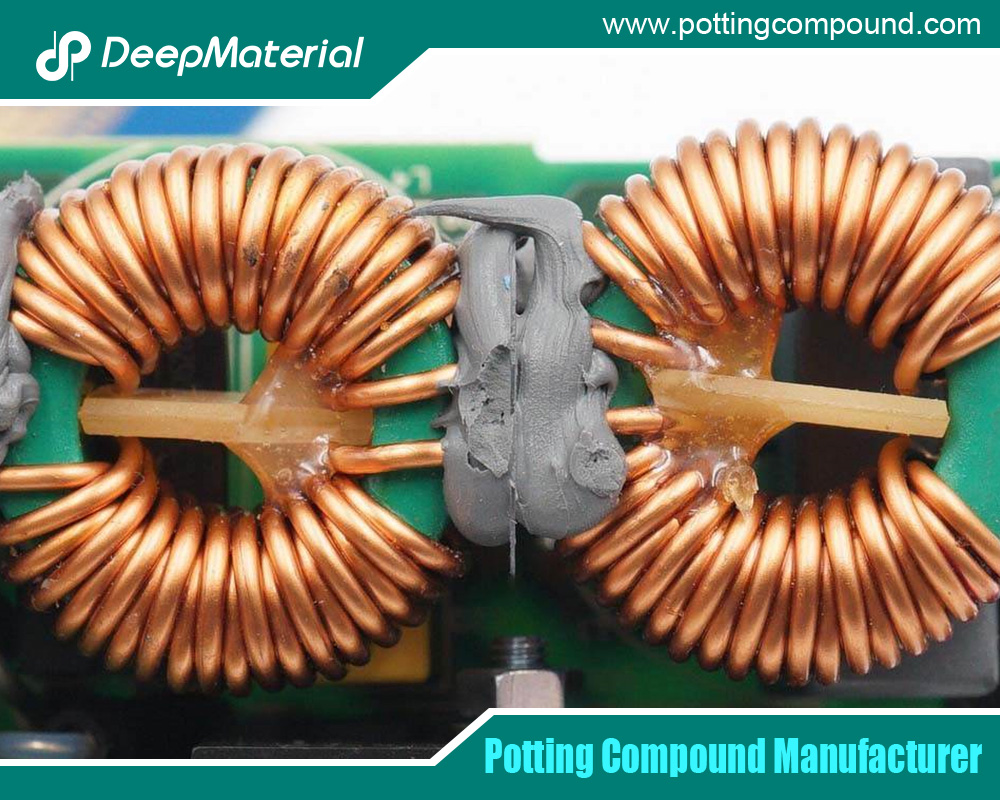

In industries ranging from electronics to automotive, epoxy potting compounds play a pivotal role in protecting delicate components from environmental factors, vibrations, and thermal stress. At the heart of producing these essential protective materials are epoxy potting compound manufacturers. These specialized companies create high-quality epoxy potting compounds and drive innovation in material science to meet diverse industry needs. This article will explore the role of epoxy potting compound manufacturers, delve into their manufacturing processes, and highlight essential considerations when selecting the right partner for your project.

The Role of Epoxy Potting Compound Manufacturers

Epoxy potting compound manufacturers are essential players in numerous industrial sectors. Their expertise extends beyond mere production to encompass material science and application-specific customization. These manufacturers typically focus on several key aspects:

- Product Customization: Tailoring formulations to meet the specific requirements of industries such as automotive, aerospace, electronics, and energy.

- Research & Development:Innovating new formulations that improve durability, thermal resistance, and other essential properties.

- Quality Control: Implementing rigorous testing to meet product quality, reliability, and safety standards.

These manufacturers create compounds that protect sensitive components against heat, moisture, shock, and chemical exposure, making their role indispensable in modern technology and engineering.

Manufacturing Process of Epoxy Potting Compounds

Epoxy potting compounds undergo a complex production process that ensures quality and efficiency. Here are the essential steps involved:

Selection of Raw Materials

Manufacturers start by choosing high-quality raw materials to achieve specific properties. These materials typically include resins, hardeners, fillers, and additives:

- Resins provide strength and chemical resistance.

- Hardeners determine the curing process and enhance durability.

- Fillers improve thermal conductivity and mechanical properties.

- Additives such as flame retardants or color pigments for additional functionality.

Formulation Development

- In this stage, manufacturers develop customized formulations to achieve desired properties. These formulations vary based on the application requirements, such as high-temperature stability or enhanced electrical insulation.

Mixing and Compounding

- Precise blending of the raw materials creates a uniform, stable compound. This phase requires specific temperature and environmental conditions to ensure consistency.

Quality Testing and Assurance

- Manufacturers conduct rigorous quality checks during and after production. Testing may involve checking for thermal resistance, adhesion, curing time, and moisture protection to meet industry standards.

Key Industries Served by Epoxy Potting Compound Manufacturers

Epoxy potting compounds are used in various industries, each with its requirements. Some of the significant sectors served include:

Electronics and Electrical

- Protection of sensitive circuitry from moisture and environmental elements.

- It enhances the insulation of electronic components to prevent electrical failures.

Automotive

- Providing a protective layer for engine control units and other automotive electronics.

- They are resisting extreme temperatures and vibrations in automotive applications.

Aerospace

- Protection against high-altitude conditions and extreme temperature variations.

- They are ensuring the longevity and reliability of flight systems.

Selecting the Right Epoxy Potting Compound Manufacturer

When choosing a manufacturer, several factors should be considered to ensure quality and suitability:

Technical Expertise and Customization Capabilities

- Look for manufacturers with a solid background in the material sciences. They are more likely to develop formulations that match your specific needs. Customization options are especially critical for industries with stringent requirements.

Product Range and Flexibility

- An extensive product range often indicates that a manufacturer can handle diverse applications. Flexibility in production volumes also matters if your business scales up or down quickly.

Compliance with Standards

- Verify that the manufacturer complies with relevant industry standards and certifications, such as ISO or UL certifications. These standards ensure quality, safety, and reliability.

Support and After-Sales Services

- Quality manufacturers often offer technical support and guidance on proper application methods. Some even provide on-site training for handling the potting compounds, which can benefit large-scale projects.

Innovations in Epoxy Potting Compounds

Epoxy potting compound manufacturers continually innovate to meet industry demands. Some notable advancements include:

- Thermal Management Solutions: Improved epoxy compounds’ thermal conductivity to effectively manage heat dissipation.

- Enhanced Electrical Properties: Innovations in insulation properties to reduce electrical interference in sensitive components.

- Environmental Sustainability: Developing eco-friendly compounds that reduce VOC emissions and ecological impact.

Understanding Key Benefits of Working with Reputable Epoxy Potting Compound Manufacturers

Opting for a reliable epoxy potting compound manufacturer provides several advantages that can benefit businesses across various sectors:

- High-Quality Compounds:Reliable manufacturers offer consistency in quality, ensuring that each batch meets the necessary specifications.

- Streamlined Production Processes:Efficient manufacturing processes contribute to timely delivery and minimize waste.

- Cost Efficiency: Long-term partnerships with reputable manufacturers can save costs, especially with bulk orders or customized solutions.

Trends in Epoxy Potting Compound Manufacturing

Epoxy potting compound manufacturing is a constantly evolving field, and several trends are currently shaping the industry:

Growing Demand for Miniaturization

- As electronic devices become smaller, manufacturers focus on compounds offering high-performance protection in limited spaces.

Increased Emphasis on Sustainability

- Due to environmental regulations and consumer demand, sustainable manufacturing practices, including eco-friendly materials and energy-efficient production, are becoming more common.

Enhanced Durability Requirements

- With more applications in harsh environments, the need for compounds that resist extreme temperatures, moisture, and chemical exposure has increased.

How to Evaluate the Quality of Epoxy Potting Compounds

To ensure you’re getting a top-quality product, here are a few qualities to look for in an epoxy potting compound:

- Thermal Conductivity: Essential for applications with high heat dissipation.

- Chemical Resistance: Important for environments where exposure to chemicals is likely.

- Adhesion:High adhesion helps the compound stay in place, even in extreme conditions.

- Viscosity and Flow: The ideal viscosity ensures easy application and proper encapsulation.

Testing and verifying these properties can help select the suitable compound for a specific application.

Conclusion

Epoxy potting compound manufacturers are crucial to industries that rely on secure and robust protection for their sensitive components. From electronics to automotive, these manufacturers provide custom solutions that meet industry demands for thermal stability, chemical resistance, and durability. Companies can make informed decisions that enhance product performance and longevity by understanding the role of these manufacturers, the manufacturing process, and the qualities to consider when choosing a supplier. Working with a reputable epoxy potting compound manufacturer ensures high-quality protection for vital components and fosters innovation for future applications.

For more about understanding epoxy potting compound manufacturers: what you need to know, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB